02-31891. Federal Motor Vehicle Safety Standards; Platform Lift Systems for Accessible Motor Vehicles, Platform Lift Installations on Motor Vehicles

-

Start Preamble

Start Printed Page 79416

AGENCY:

National Highway Traffic Safety Administration (NHTSA), Department of Transportation.

ACTION:

Final rule.

SUMMARY:

This document adopts a new rule establishing two new safety standards: An equipment standard specifying requirements for platform lifts; and a vehicle standard for all vehicles equipped with such lifts. The new equipment standard will require platform lift manufacturers to ensure that their lifts meet minimum platform dimensions and maximum size limits on platform protrusions and gaps between the platform and either the vehicle floor or the ground. The standard also requires handrails, a threshold warning signal, and retaining barriers for lifts. Performance tests are specified for wheelchair retention on the platform, lift strength, and platform slip resistance. A set of interlocks is prescribed to prevent accidental movement of a lift and the vehicle on which the lift is installed. The vehicle standard will require vehicle manufacturers who install lifts to use lifts meeting the equipment standard, to install them in accordance with the lift manufacturer's instructions, and to ensure that specific information is made available to lift users. The purpose of the two standards is to prevent injuries and fatalities during lift operation and to promote the uniformity of Federal standards and guidelines for platform lifts.

DATES:

Effective Date: This rule is effective December 27, 2004.

The incorporation by reference of the publications listed in the rule is approved by the Director of the Federal Register as of December 27, 2004.

Petitions: Petitions for reconsideration must be received by February 10, 2003.

ADDRESSES:

Petitions for reconsideration should refer to the docket and notice number of this document and be submitted to: Administrator, National Highway Traffic Safety Administration, 400 Seventh Street, SW., Washington, DC 20590.

Start Further InfoFOR FURTHER INFORMATION CONTACT:

For non-legal issues, you may call William Evans, Office of Crash Avoidance Standards, at (202) 366-2272.

For legal issues, you may call Rebecca MacPherson, Office of the Chief Counsel, at (202) 366-2992.

You may send mail to both of these officials at National Highway Traffic Safety Administration, 400 Seventh St., SW., Washington, DC 20590.

End Further Info End Preamble Start Supplemental InformationSUPPLEMENTARY INFORMATION:

Table of Contents

I. Background

II. Summary of the SNPRM

III. Summary of the final rule and key differences between it and the SNPRM

A. Manufacturer responsibilities under the final rule

1. Platform lift manufacturers

2. Vehicle manufacturers

B. Platform lift requirements

IV. Summary of public comments

V. Need for safety standards for platform life systems

VI. Differing safety needs for private and public use platform lifts

VII. Effective dates

VIII. Platform lift requirements

A. Threshold warning signal

B. Platform lift operational requirements

1. Maximum platform velocity

2. Maximum platform acceleration

3. Maximum noise level of public use lifts

C. Environmental resistance

D. Platform requirements

1. Unobstructed platform operating volume

2. Platform surface protrusions

3. Gaps, transitions, and openings

4. Platform deflection

5. Edge guards

6. Wheelchair retention

7. Inner roll stop

8. Handrails

9. Platform markings on public use lifts

10. Platform lighting on public use lifts

11. Platform slip resistance

E. Structural Integrity

1. Fatigue endurance

2. Proof load

3. Ultimate load

F. Platform free fall limits

G. Control systems

H. Jacking prevention

I. Backup operation

J. Interlocks

K. Operations counter

L. Owner's manual insert

M. Installation instruction insert

N. Test conditions and procedures

1. Test devices

2. Static load test I—working load

3. Static load test II—proof load

4. Static load test III—ultimate load

5. Interlock test procedures

IX. Vehicle requirements

X. Benefits of the final rule

XI. Costs of the final rule

XII. Miscellaneous Issues

A. Axle weight limitations

B. Definitions in the FMVSS No. 403

C. Delayed compliance with the ADA

XIII. Rulemaking Analyses and Notices

Appendix to preamble

I. Background

We initiated this rulemaking proceeding concerning safety standards for platform lifts to provide practicable, performance-based requirements and compliance procedures for the regulations promulgated by the Department of Transportation (DOT) under the Americans with Disabilities Act of 1990 [1] (ADA) and to ensure the safety of vehicles equipped with those lift systems. Under our statutory authority,[2] we establish Federal motor vehicle safety standards (FMVSS) to reduce motor vehicle crashes and the resulting deaths, injuries, and economic losses. Each standard must be practicable, meet the need for motor vehicle safety, and be stated in objective terms.[3] The ADA does not relieve us of these requirements. Our authority extends to both motor vehicles and motor vehicle equipment. Further, we are authorized to regulate non-operational vehicle safety i.e., safety while being maintained, serviced or repaired or while being entered or exited) as well as operational vehicle safety (i.e., safety while being operated on public roads).

Today, we are adopting a final rule that establishes two new safety standards. The first, FMVSS No. 403, Platform lifts systems for motor vehicles, establishes minimum performance standards for platform lifts designed for installation on a motor vehicle. The second, FMVSS No. 404, Platform lift installations in motor vehicles, places specific requirements on vehicle manufacturers or alterers who install the lifts on new vehicles. Under this final rule, lift manufacturers will have to certify that their lifts meet the requirements of FMVSS No. 403, and manufacturers or alterers of new vehicles will have to ensure that the lifts are installed according to the lift manufacturer's instructions by certifying compliance with FMVSS No. 404. Affixing a label on the lift will effect the certification of compliance with FMVSS No. 403. Certification of compliance with FMVSS No. 404 will be on the certification label already required of vehicle manufacturers and alterers under 49 CFR part 567.

Title II of the ADA requires newly purchased, leased, or remanufactured vehicles purchased by public entities, like municipalities and regional transit authorities, and used in fixed route bus Start Printed Page 79417systems to be readily accessible to and usable by individuals with disabilities, including individuals who use wheelchairs, canes, and walkers. Title II also requires a public entity operating a demand-responsive transportation system to obtain accessible vehicles unless the system, when viewed in its entirety, provides individuals with disabilities with a level of service equivalent to that provided for individuals without disabilities. Title II further requires public entities operating a fixed route bus system (other than a bus system which provides only commuter service) to provide complementary paratransit and other special transportation services to individuals with disabilities. Title III requires that designated public transportation, provided by private entities, be readily accessible to and usable by individuals with disabilities, including individuals who use wheelchairs, canes, or walkers.

The ADA directed DOT to issue regulations to implement the transportation vehicle provisions in Titles II and III. Additionally, the ADA required the Architectural and Transportation Barriers Compliance Board (ATBCB) to issue guidelines to assist DOT in establishing these regulations.[4] The regulations issued by DOT must be consistent with those guidelines.[5] On September 6, 1991, ATBCB published its final guidelines which specify that to be considered accessible, a vehicle must be equipped with a lift or other level change mechanism and have sufficient clearance to permit a wheelchair to reach a wheelchair securement location once it is on the vehicle. (56 FR 45530) ATBCB stated that “NHTSA is the appropriate agency to define safety tests” for platform lifts.[6] On the same day, DOT implemented the ADA by publishing a final rule establishing accessibility regulations at 49 CFR part 38, Transportation for Individuals with Disabilities, Subpart B—Buses, Vans and Systems, and by incorporating and requiring compliance with the September 6, 1991 guidelines issued by the ATBCB. (56 FR 45584) This document collectively refers to the ATBCB's final accessibility guidelines and DOT's final rule as the “ADAAG”.

Issuing motor vehicle safety standards provides the best way to ensure that only lift systems that comply with objective safety requirements are placed in service. The standards adopted today will ensure a level of safety and uniformity that should instill confidence in the user population.

Additionally, our regulatory framework provides specific procedures to address quickly vehicles and motor vehicle equipment that are out of compliance or contain a safety defect, including a procedure that can be followed to remedy the situation if a problem is found.

We believe the standards will be of benefit to lift manufacturers, vehicle manufacturers, alterers, and modifiers, as well as consumers. The platform lift standard was drafted to include or exceed all existing government (Federal Transit Administration (FTA), ADA, Department of Veteran's Affairs (DVA), California Title 13) and voluntary industry (e.g., Society of Automotive Engineers (SAE)) standards.[7] A chart detailing which voluntary and Federal standards correspond to each of the requirements proposed in this document can be found at the end of the document in Appendix A. A lift manufacturer who certifies its lift to the standard should have confidence that the lift would also meet other major U.S. standards currently in force without additional testing.

We published a notice of proposed rulemaking (NPRM) on February 26, 1993 proposing to create a new safety standard for buses equipped with lift systems (58 FR 11562). On July 27, 2000, we published a supplemental notice of proposed rulemaking (SNPRM) (65 FR 46228), in part because the comments on the 1993 NPRM were over six years old. That notice provided for a 60-day comment period.

II. Summary of the SNPRM

The SNPRM differed from our original proposal in several respects. Most notably, the scope of our proposal was expanded to platform lifts installed on all motor vehicles rather than just buses. Second, we decided to propose two standards, instead of one, and to assign each of them a different Federal motor vehicle safety standard number: Standard No. 141, instead of Standard No. 401, and Standard No. 142 (these designations have been changed to FMVSS No. 403 and FMVSS No. 404, respectively). We believed that two standards, one addressing the platform lift and another addressing the vehicle on which the lift is installed, would best protect lift occupants and bystanders. This two-prong approach is the same one we took in regulating underride guards.

Other significant changes from the NPRM were the proposal of additional interlock requirements, improved wheelchair retention and platform slip resistance tests, and, in some instances, lesser compliance standards for lifts installed on vehicles typically used solely for private transport.

The proposed equipment standard, first introduced in the SNPRM, tentatively required platform lift manufacturers to ensure that their lifts meet minimum platform dimensions and maximum size limits on platform protrusions and gaps between the platform and either the vehicle floor or the ground. The proposed standard also contemplated requiring handrails, a threshold warning signal, and retaining barriers for lifts. Performance tests were specified for wheelchair retention on the platform, lift strength, and platform slip resistance. A set of interlocks was proposed to prevent accidental movement of a lift and the vehicle on which the lift is installed.

The proposed vehicle standard contemplated requiring vehicle manufacturers who install lifts to use lifts meeting the equipment standard, to install them in accordance with the lift manufacturer's instructions, and to ensure that specific information is made available to lift users.

Since the purpose of the two standards is to prevent injuries and fatalities during lift operation and to promote the uniformity of Federal standards and guidelines for platform lifts, we drafted the SNPRM both with the intent of protecting lift users aided by canes or walkers as well as lift users seated in wheelchairs, scooters, and other mobility devices.

We stated the costs associated with the proposed rule should be relatively low because we believed that most lift manufacturers are already complying with the existing voluntary and Federal standards. Accordingly, we believed lift manufacturers generally would not need to make substantial changes to their existing lifts, although some work may be needed to fully comply with the lift standard.Start Printed Page 79418

III. Summary of the Final Rule and Key Differences Between It and the SNPRM

A. Manufacturer Responsibilities Under the Final Rule

1. Platform Lift Manufacturers

As in the SNPRM, the responsibility for lift design and performance ultimately rests with the lift manufacturer. The lift manufacturer must not only provide a lift that complies with all of the performance requirements set forth in today's rule, but also installation instructions that provide sufficient direction to the lift installer so that the lift, when properly installed, fully complies with all the applicable requirements of FMVSS No. 403. Additionally, the lift manufacturer must determine, at the time of certification, whether the lift is appropriate for use by the general public rather than by a single individual.

2. Vehicle Manufacturers

Vehicle manufacturers also bear responsibility under today's rule. While they are not responsible for the design of a particular lift, they are responsible for installing a lift in a manner consistent with both FMVSS No. 404 and the lift manufacturer's installation instructions. Additionally, they are responsible for making sure that only public use lifts are installed on buses, school buses, and multi-purpose vehicles (MPVs), other than motor homes, with a GVWR greater than or equal to 4,536 kg (10,000 lb). Finally, they are responsible for assuring that the lift, as installed, meets all the operational requirements that are vehicle dependent. That is to say, the installed lift must operate as mandated by today's rule.

B. Platform Lift Requirements

Although we have adopted large portions of the regulation as set forth in the SNPRM, we have made numerous changes in today's final rule. First, we have decided not to adopt three of the ten interlocks proposed in the SNPRM. In addition, we have changed the weight-based distinction for determining whether an MPV must meet the more stringent requirements based on anticipated use by members of the general public and those requirements for lifts likely to only be used by a single individual. The determination of when a lift must meet the public use requirements has been increased to a vehicle GVWR of 4,536 kg (10,000 lb). We have also extended the rule's effective date from one year to two years. Finally, we have specified weight limits necessary to activate the interlocks and alerts required by today's rule. We have also changed the standard load for private use lifts from 272 kg (600 lb) to the manufacturer's specified load or 181 kg (400 lb), whichever is greater.

IV. Summary of Public Comments

We received 25 comments in response to the SNPRM. Four industry associations submitted comments on behalf of their members. The National Mobility Equipment Dealers Association (NMEDA) represents businesses that modify vehicles for persons with disabilities. The American Bus Association (ABA) represents bus operators, manufacturers, and suppliers of products and services used by the bus industry. The United Motorcoach Association (UMA) represents motorcoach operators and suppliers. The American Public Transportation Association (APTA) represents transit systems, product and service providers, and state associations and departments of transportation. According to APTA, its members serve over 90 percent of all people who use public transportation in the United States and Canada.

The five lift manufacturers who commented, Stewart & Stevenson, Braun Corp, Ricon Corp., Lift-U, and Transport & Trolley, represent both the personal use market and the paratransit market. Seven companies representative of vehicle manufacturers also commented on the SNPRM. Blue Bird and Collins Industries (Collins) manufacture school buses. American Transport Corp. (ATC) and Motor Coach Industries (MCI) manufacture paratransit, or over-the-road buses. Prevost and VanHool are also bus manufactures, but did not specify in their comments what types of buses they manufacture. Ride-Away Corp. alters and modifies personal vehicles for persons with disabilities.

Four state agencies, the Wisconsin Department of Transportation (Wisconsin DOT), the Oregon Department of Transportation (Oregon DOT), the Michigan Department of Transportation (Michigan DOT), and the New Jersey Transit Authority (NJ Transit), offered comment, as did two private citizens and one paratransit bus operator (DMN Enterprises). Finally, we received limited comments from R.C.A. Rubber, a rubber tread manufacturer, and Bendix Commercial Vehicle Systems, a manufacturer of air brake systems and components.

In general, the comments on most portions of the proposed standards set forth in the SNPRM were supportive. However, some commenters expressed significant, overarching concerns about the possible impact of two new safety standards in this area. Specifically, several lift manufacturers raised concerns over the cost of meeting the new requirements and whether the agency had demonstrated a safety need sufficient to justify the proposed standards. Further, several over-the-road bus manufacturers and operators raised concerns about whether a new standard would delay full implementation of the ADA.

The state governments that commented were largely supportive of the proposal made in the SNPRM. For example, the Wisconsin DOT stated that all lifts owned or operated by state or local governments within the state already met or exceeded the proposed requirements.

V. Need for Safety Standards for Platform Lift Systems

As discussed in the SNPRM, we recognize that the vast majority of the American public does not need to use platform lifts. We believe, however, that individuals who do need to use them should have assurance that lifts are as safe as possible and should be protected from the risk associated with using unregulated equipment.

We acknowledge that there is a dearth of information regarding injuries associated with malfunctioning lifts. We believe that, from 1991 to 1995, at least 299,734 wheelchair users were injured. That figure, based on data collected by the Consumer Product Safety Commission during that time-frame as part of its National Electronic Injury Surveillance System (NEISS) database, is for all types of circumstances. 7,121 of these users were injured as a result of some interaction with a motor vehicle. In 1990, the Centers for Disease Control determined that 1.411 million people in the United States use wheelchairs. Thus, the NEISS figure of 299,734 represents an overall injury rate among the wheelchair-using population of slightly more than 21 percent. While only 7,121 of these people were injured during the five-year period as a result of interaction with a motor vehicle, 26% (1,366) were the direct result of some unspecified type of lift malfunction. When broken down on an annual basis, the NEISS data projects 248 injuries per year.

We anticipate that more people will use lifts on motor vehicles as the ADA requirements make transportation more accessible to individuals with mobility impairments and as the proportion of older people in the general population increases. As the number of lift-equipped vehicles increases, the number of lift-related injuries is also Start Printed Page 79419likely to go up. Indeed, our analysis has already revealed an upward trend in the number of lift-related injuries.

We believe there may be considerably more injuries due to malfunctioning lifts than the numbers suggest. Any analysis of deaths or injuries based on motor vehicle-incidents will necessarily under-represent the scope of the problem. Since lift-related injuries frequently are not reported as a motor vehicle incident, no police report is filed. Consequently, the event is not entered in the data bases that we search for injury and death information related to motor vehicles (e.g., police reported incidents from states, NASS, and FARS). Additionally, the injury count understates the number of actual injuries because it does not include incidents in which the injured persons were treated at small hospitals, emergency care centers, or doctor's offices.

Recognizing the dearth of available data, we asked commenters to respond to several questions that we posed in the SNPRM. Specifically, we sought comment on the size of the potential lift using population; the number of lifts installed on motor vehicles since 1997, with a breakdown of that number between lifts that were installed by lift manufacturers and lifts that were installed by someone else; the number of MPVs with ramps instead of lifts; and how many lifts were installed on vehicles prior to their first sale for purposes other than resale, with breakdown by entity that installed them. We also sought comment on which of the proposed requirements would most contribute to a reduction of injury and why.

Collins noted that approximately 30% of the buses it builds are equipped with platform lifts. It further noted that while in 1997 approximately 15% of the buses it manufactured were equipped with a lift-accessible service door but were not equipped with a lift, that number has shrunk to about 3%. Collins posited that the new regulation would eliminate that portion of the market. ATC stated that since 1997 it has installed approximately 858 lifts in their own vehicles and had produced approximately 171 buses with lift accessible doors but without a lift.

Ricon estimated that someone other than the vehicle manufacturer installs approximately 40% of lifts. It noted that the percentage of lifts installed by lift manufacturers is negligible. NJ Transit stated that since 1997 all of its transit buses, cruisers, minibuses and vans have had lifts installed by the vehicle manufacturer.

NMEDA noted that local dealers, who may be alterers or modifiers, install the vast majority of personal use lifts. It stated that local dealers are also responsible for installing a smaller majority of commercial lifts.

The ABA and UMA stated that NHTSA had not demonstrated a sufficient safety need for the adoption of new FMVSSs. UMA stated that it had contacted its user and insurance members and had not identified a single instance of a disabled traveler being injured or killed because of a lift design problem. It maintained that the injuries of which it is aware have all been a result of poor maintenance or training practices. ABA stated that it believed the dearth of injury data after the passage of the ADAAG indicates that lifts perform well under the current set of lift requirements and that no further regulation is needed.

The ABA and UMA and MCI also maintained that the proposed standards, if adopted, would delay the implementation of ADA requirements on over-the-road buses as bus operators will delay purchasing lift-equipped buses until bus and lift manufacturers have retooled their designs so as to comply with the new standards. Stewart & Stevenson noted that the lift industry has already expended significant development costs in meeting the ADAAG and California Title 13 requirements. It stated that the proposed requirements would impose additional costs on the lift manufacturer, vehicle manufacturer, and consumer.

Mirroring the argument by UMA that operator error was a larger problem than lift malfunction, DMN Enterprises and MCI argued that the proposed standards do not adequately consider the presence of a trained lift operator on transit vehicles. DMN Enterprises also believed that the costs might be minimal for several of the proposed requirements, but that the additional costs in several areas such as platform deflection, interlocks, and angular orientation during free fall would require major redesign and potentially high costs. It also asked why NHTSA did not consider adopting the California Title 13 test requirements rather than devising new requirements. Finally, it urged NHTSA to commit to developing standards addressing ramps and securement devices since the transit industry is moving towards greater use of ramps and less on platform lifts.

We acknowledge the dearth of data typically relied on by NHTSA in determining whether a particular safety standard meets the need for motor vehicle safety. However, as discussed above, we do not believe that the lack of concrete data necessarily means that there is no need to regulate the safety of platform lifts. Our determination that today's standards meet the requisite need for safety is based primarily on engineering assessments made by the SAE, FTA, and DVA, and verified by NHTSA, that certain safety features are needed for platform lifts. Today's rule merely establishes measurable performance standards that incorporate the existing recommended practices and guidelines.

VI. Differing Safety Needs for Private and Public Use Platform Lifts

In the SNPRM, we discussed whether it would be appropriate to have fewer requirements for platform lifts installed on MPVs than for those installed on buses. The reason for that difference is that lifts designed for MPVs have different usage patterns than those designed for buses. We proposed that buses and MPVs greater than 3,200 kg (7,100 lbs) meet stricter requirements than other vehicles. At that time, we believed that this was an appropriate cut-off, given that most of these larger vehicles are for public transit and paratransit use, instead of individual use. Since the lifts on these vehicles will generally be subjected to more stress and cyclic load and will be used by a larger and more varied population, more requirements as to platform size, controls, handrails and lighting appeared appropriate. We noted that where the ADA imposes requirements on commercial entities and those entities use a vehicle that weighs less than 3,200 kg, the commercial entity would still have to meet the applicable ADA requirement. We then requested comment on whether it is appropriate to have less stringent requirements for lifts designed for installation on motor homes, trucks, truck tractors, trailers, and MPVs less than 3,200 kg. We also sought comment on whether 3,200 kg was the correct breakpoint, and if not, what was.

Several commenters, including individuals, lift manufacturers, modifiers and vehicle manufacturers stated that the breakdown of lift requirements based on GVWR was unworkable since many individuals purchase vehicles that have a GVWR greater than 3,200 kg to accommodate the needed vehicle modifications or to provide additional cargo capacity. The majority of commenters argued that the division should be based on whether the lift would be used in a commercial setting or solely for personal use. NMEDA suggested the lift manufacturers be required to mark their lifts as suitable for personal or Start Printed Page 79420commercial use. Collins and Ride-away suggested the GVWR break-point be raised above 3,200 kg, with Collins suggesting a division at 4,536 kg (10,000 lb) GVWR.

Additionally, a private citizen and MCI argued that the requirements for private-use lifts should be no less stringent than those used for transporting the general public. MCI noted that operators of public-use lifts are trained in the proper operation of the equipment and, as demonstrated by NHTSA's own data analysis, that fewer injuries occur on lifts installed in buses than on lifts installed in MPVs. Braun supported adopting less stringent requirements for personal-use lifts.

As discussed in the SNPRM, defining a safety standard solely in terms of whether the vehicle or motor vehicle equipment is intended for private or public use fails to meet the statutory meaning of objectivity unless the agency clearly defines private and public use in a manner that is readily applicable to lift manufacturers and vehicle manufacturers. We are, however, persuaded that a break-point of 3,200 kg for MPVs will likely place unreasonable restrictions on many individuals who use their vehicle for purely personal transportation. Accordingly, we have raised the upper limit for MPVs that may use lifts that are not certified to all of the standard's requirements to 4,536 kg GVWR. Not only is this one of the break-points NHTSA has traditionally used to differentiate between private and commercial vehicles, but we also believe this break-point will accommodate almost all MPVs purchased for personal use.

As proposed in the SNPRM, the lesser requirements will also be applicable to those lifts designed for use on motor homes, trailers and tractor-trucks, since these vehicles are generally not used to transport the general public. The lifts that meet the lesser requirements shall be certified as DOT-private use compliant. Private use is defined in the standard as those lifts designed for installation on motor homes, trailers, truck tractors and MPVs with a GVWR less than 4,536 kg, and that are certified as compliant with the lesser requirements. The certification label on these lifts shall bear the statement “DOT-private use lift”.

We note that the requirements of the ADA still apply to all lifts installed on vehicles used as public conveyances, either by public entities or by private entities that transport members of the general public, regardless of vehicle size. Thus, in many instances a lift manufacturer may choose to manufacture a lift that meets the stricter requirements, either because it does not wish to develop a separate lift design, or because the lift will be installed on a smaller MPV that is used for the transportation of the general public. Under today's rule, lifts designed for use on vehicles smaller than 4,536 kg be certified to the stricter requirements. Lifts designed for installation on all buses and on MPVs with a GVWR in excess of 4,536 kg must be certified to the stricter requirements and will be defined in the standard as public-use lifts. Likewise, those lifts that are certified as meeting the stricter requirements are defined as public-use lifts, even if they may be installed on vehicles that are not buses or MPVs with a GVWR less than 4,536 kg. The certification label on these lifts shall bear the statement “DOT-public use lift”.

Throughout the rest of this document, the differences in requirements, both in the final rule and as discussed in the SNPRM, will be discussed in terms of private use lifts and public use lifts.

VII. Effective Dates

We received ten comments on the proposed one-year effective date. Three of the commenters (Braun, MCI and Collins) believed a one-year effective date was sufficient, although Braun indicated that many of the proposed requirements—particularly the proposed interlocks—would require costly and complex product redesign which would require additional leadtime. Other commenters maintained that too many changes were required to be achieved in one year. These commenters suggested an effective date ranging from two to five years. The commenters were particularly concerned about the time needed to comply with the proposed interlock requirements.

NMEDA commented that the requirements should only apply to lifts manufactured after the effective date and installed on new vehicles. In a similar vein, APTA was concerned that the proposed regulations did not address lifts installed on vehicles that had been purchased before the effective date.

NJ Transit believed the effective date should exempt existing bus orders placed by mass transit authorities as such orders can carry over multiple years. It argued that changing lift equipment in the middle of a bus order could be confusing to customer, and could increase manufacturing and maintenance costs.

Based on the comments, we have decided to adopt a two-year effective date. We believe this time frame will provide lift manufacturers sufficient time to meet any new requirements. As discussed in the SNPRM, most of the requirements adopted in today's rule are already part of an existing standard or guideline. Accordingly, lift manufacturers should not need a significant amount of time to ensure their lifts comply with the new FMVSS. As to NMEDA's and APTA's concern that the new standards not apply to lifts or vehicles manufactured before the effective date, we note that both FMVSS No. 403 and FMVSS No. 404 have a two-year effective date. Thus, only lifts manufactured after the effective date need to be certified as compliant with FMVSS No. 403 and only vehicles manufactured after the effective date need to be certified as compliant with FMVSS No. 404. FMVSS No. 404 will not apply to vehicles manufactured before the effective date even though those vehicles may have FMVSS No. 403 compliant lifts. However the use of a compliant lift, even on the older vehicles, should provide an added measure of safety.

We are unable to provide a separate effective date for vehicles that are covered by multi-year purchase orders, as NJ Transit urges. Such a provision would be non-objective and impossible for us to enforce. However, we believe the two-year delay in the effective date will provide transit operators, such as NJ Transit, to make whatever contract modifications are necessary on existing purchase orders and to ensure that all future purchase orders specify the installation of compliant lifts.

VIII. Platform Lift Requirements

Threshold Warning Signal

In the SNPRM we proposed to require a threshold warning alarm to alert vehicle occupants near an operating lift. For private use lifts, the alarm could be either audible or visual. Under the proposal, public use lifts would need to have both a visual and an audible alarm since these larger vehicles are generally used for commercial transport. In all vehicles, the alarm would have needed to warn lift users if the lift platform were more than one inch below the vehicle's floor reference plane and if any portion of the platform threshold area [8] were occupied by any portion of the lift occupant's body or any piece of equipment. This warning requirement Start Printed Page 79421was based on an SAE recommended practice specifying a warning if the lift user is within 18 inches of the platform and the platform is more than one inch below the vehicle's floor reference plane.

We stated in the SNPRM that we considered a warning alarm to be particularly important in transit and paratransit vehicles where more than one individual may use the lift sequentially. It would also be important in any personally licensed vehicle in which the lift is fitted such that the user backs onto the lift from the floor of the vehicle (this typically occurs on lifts fitted to the rear of the vehicle), since we did not believe such systems posed the same type of risk to the lift occupant or bystanders. The proposed requirement would not have applied to rotary lifts where loading takes place entirely over the surface of the vehicle's floor. We sought comment on whether an audible or visual threshold warning should be required and whether the warning would avoid injuries to users caused by an out-of-position platform. We also sought comment on whether a minimum size or weight should be specified to trigger the warning (and, if so, what that size or weight should be).

Additional concerns were raised about the effect a visual or audible alarm could have on individuals with certain medical conditions such as epilepsy. Accordingly, Ricon and Braun suggested that NHTSA allow a mechanical threshold barrier as an alternative to an audible or visual alarm. In response to our question as to whether a minimum weight should be specified to trigger the threshold alarm system, Braun and NMEDA argued that the warnings only be required to activate when the sensors detected a weight greater than 50 lb.

The Oregon DOT supported requiring an audible threshold-warning signal. It maintained such a signal would not only protect lift occupants during sequential loading, but would also warn a driver or attendant when a passenger with impaired cognitive ability approached the lift door when the lift was fully deployed.

Other commenters opposed the adoption of a threshold warning alarm, particularly for lifts used in a commercial environment. Prevost posited that a threshold-warning requirement should only be required in those instances where the lift occupant must operate the lift without assistance. Along with MCI, it maintained that the requirement should not apply to lifts installed on over-the-road buses since the drivers of these buses have been trained to load and offload disabled individuals from the bus, obviating the need for an alarm.

Stewart & Stevenson stated that most vehicle manufacturers already have a visual or audible warning that is activated when the lift is activated. It stated that these warning systems are effective, even though they are not activated whenever an individual is within 18 inches of the lift. It further averred that imposing such a requirement would increase the cost of lift design and compliance with no associated benefit. RICON, Braun, NMEDA and Prevost all stated that the proposed threshold area should be reduced to twelve inches, at least for non-commercial, non-transit vehicles. Braun noted that an eighteen-inch threshold area could consume as much as 30 percent of the interior width of a standard-size van.

MCI stated that while SAE J2090, Design Considerations for Wheelchair Lifts for Entry to or Exit from a Personally Licensed Vehicle, specified a threshold warning system, it is unaware of any manufacturer of personal use lifts who actually incorporates this feature into its lift design. It additionally claimed that it has never heard of an accident that would have been avoided if the lift had been equipped with a threshold-warning signal. Finally, MCI noted that often the wheelchair securement location is within the 18-inch area proposed in the NPRM and that requiring the alarm to go off whenever that area is occupied and the lift is in motion could draw undue attention to wheelchair occupants.

Section 4.4.6 of the State of California Department of Rehabilitation's Specifications for Adaptive Driving Equipment has required threshold warning systems for lifts installed on private vehicles since 1985. It adopted this requirement after six clients of the state's Mobility Evaluation Program were killed after backing their wheelchair off a vehicle when they thought the platform was in place. Since instituting this requirement, no other falls have come to the attention of the Mobility Equipment Program. Currently Braun provides a platform warning alarm system as optional equipment to at least some of its lifts. We believe that the vehicle modifiers are placing the warning devices in vehicles equipped with lifts manufactured by other companies are meeting the California requirements by installing simple weight detection devices on the floor of the vehicle.

Given the risk involved in backing off a vehicle when the lift is not properly positioned, we have decided to adopt the requirement for a threshold warning system as proposed in the SNPRM. Under today's rule, the threshold warning system must activate whenever the platform is more than 25 mm (1 in) below the vehicle floor reference plane. Several types of detection systems may be used to satisfy this requirement. In order to test for compliance with the requirement we have decided to place one front wheel of the wheelchair test device specified in the standard within the threshold area. This will place approximately 11.3 kg (25 lb) on the threshold. This amount of weight roughly replicates the weight of the lightest portion of an average wheelchair or half the weight of a child who may be using the lift unattended. We have decided against specifying a particular minimum weight because wheelchairs will place slightly differing amounts of weight depending on design. We believe the threshold should reasonably detect the weight of any occupant in a mobility device and any bystander who is likely to be unattended. We note that the rough approximation of weight represented by placing one wheel of a mobility device in the threshold area should allow individuals to place light objects, such as books or handbags, within the area without triggering the alert.

We are unconvinced that there is no need to require a threshold warning alert for over-the-road buses. Prevost and MCI may be correct that in general the lift operators on over-the-road buses have received specialized training in how to use the lift. However, we have no control over the level of training provided. Additionally, the lift operator may actually operate the lift from a position remote from the lift platform, such as the driver's seat. In such an instance, the operator would not be able to ensure that no other vehicle occupants were a safe distance from the lift throughout the range of lift operations.

We believe the 18-inch threshold area requirement is important for safety, particularly for wheelchair users who back onto the lift platform from the vehicle floor. If the threshold is reduced to twelve inches, as suggested by commenters, the wheelchair may be so close to the edge of the vehicle floor that the occupant will be unable to react in time to prevent the wheelchair from continuing the wheelchair's movement off the edge of the vehicle floor. The standard only requires the alert be activated when the lift is deployed, the threshold is occupied, and the lift platform is more than one inch below the level of the vehicle floor. In private vehicles the alert would only be activated when the lift is deployed and Start Printed Page 79422a vehicle occupant is either in the threshold area or simultaneously on the threshold and the platform after the lift had started moving. The same is true for transit and paratransit buses, except the alert could also activate while the lift was being used properly and another occupant was in the threshold area. While the commenters may be correct that the alert will notify all vehicle occupants that the lift is being operated, we do not believe the alert is any more likely to draw attention to a lift user than the operation of the lift itself.

Today's requirement specifies that the audible alert be at least 85 dBA and the visual alert have a frequency of 1 to 2 Hz. We believe these specifications are unlikely to lead to seizures in or cause other medical or physical impairments to vehicle or lift occupants. The 85-dBA level of the audible alarm is a frequently used level for enunciators. An individual can be exposed to this sound level for the length of time the alarm will operate without sustaining hearing loss or other negative repercussions. The low frequency flash of the visual alert (1 to 2 Hz) is in line with the frequency of warning flashers commonly used in automotive and highway applications. The flash frequency is also in line with our existing requirements in FMVSS No. 108, Lamps, reflective devices, and associated equipment, which incorporates by reference SAE recommended practice J590B, Turn Signal Flashers, for the visual flash rate of hazard warnings. SAE J590B stipulates a rate of 60 to 120 flashes per minute, which translates to a frequency of 1 to 2 Hz. We are unaware of any seizures related to the use of hazard devices required under FMVSS No. 108.

We believe lift systems that use a mechanical barrier to prevent a vehicle occupant from falling off the edge of the vehicle are used only rarely, if at all. Certainly such devices are not addressed by existing recommended practices or guidelines. In any case, we have decided against allowing such a barrier as an alternative to the threshold warning alert, as we have some concerns about the safety of such a device. Such a barrier could retain powered wheelchairs, but they would also create a tripping hazard for persons using canes and walkers. Additionally, mechanical barriers could impinge on an occupant's ability to exit the vehicle during an emergency situation. If warning systems other than those related to a threshold warning alert are developed, NHTSA could change the standard to allow such systems.

B. Platform Lift Operational Requirements

1. Maximum Platform Velocity

We proposed maximum platform operating speeds for the safety of lift users, especially standees (e.g., individuals who use a cane or walker). The SNPRM specified a maximum vertical and horizontal velocity of the platform of 152 mm/s (6 in/s) in order to assure the safety of those on or near the lift and to be consistent with the ADAAG (49 CFR 38.23(b)(10)) and FTA guidelines (section 2.5.11), which also allow a maximum velocity of 152 mm/s (6 in/s).

Based on our review of the ADA standard, we also decided to propose that during stowing and deploying, the lift platform would have a maximum vertical and horizontal velocity of 305 mm/s (12 in/s). The purpose of this requirement was to reduce the potential injuries to bystanders and lift users. We requested comment on safety need for velocity limits while platform is stowing and deploying and whether any commenters knew of any instances where someone was injured because the lift was stowing or deploying too quickly.

We received comments both supporting and opposing the adoption of a maximum operating velocity during the stowage and deployment portion of lift operation. Collins noted that while it no longer manufacturers platform lifts, it knew of very few accidents that resulted from excessive folding speed when it was manufacturing lifts. Braun also knew of no incidents related to excessive stowage or deployment speed. It stated, however, that 305 mm/sec (12 in/sec) appeared a reasonable speed to prevent injuries. Braun also requested the agency specify where on the lift to measure a maximum radial velocity during the stowage and deployment operations, suggesting a point 610 mm (24 in) from the platform pivot.

We have decided to adopt a requirement limiting the maximum velocity of platform lifts throughout the lift's range of operation. We are not persuaded that specifying a maximum platform velocity, both throughout the range of passenger operations and the stowage and deployment operations, imposes an unreasonable burden on the lift manufacturer. Today's requirement is based on existing requirements, which may explain why commenters are unaware of any accidents related to excessive platform velocity. However, the fundamental risk of injury from a lift that is moving too quickly remains unless there is a requirement that limits the lift's operating velocity.

We agree that it is appropriate to specify where on the lift the agency will measure maximum velocity during the range of operation. The regulatory text has been changed accordingly. Additionally, we recognize that some lifts use a hinged platform lift that pivots down when deployed and up when stowed. On these lifts the highest platform velocity occurs at the outer edge of the platform. In order to clarify that the maximum velocity of these lifts are covered by the standard, we have changed the regulatory text to specify that during the stowage and deployment portions of lift operation no portion of the lift shall exceed 305 mm (12 in/sec). Otherwise the requirements for maximum operating velocity have been adopted as proposed in the SNPRM.

2. Maximum Platform Acceleration

We decided to propose in the SNPRM an acceleration limit of 0.3 g with the platform both loaded and unloaded. The acceleration would be measured along axes horizontal and perpendicular to the lift platform. The no load condition was intended to ensure that even very light occupants would be protected against a sudden increase in lift speed, since very small children may use lifts, especially in school buses. By requiring compliance at any load in between the extremes, we intended to ensure that acceleration remains within the desired limits. While the proposed test procedure was based on the one specified in SAE recommended practice J211, Instrumentation for Impact Test, we proposed to depart from that test procedure by measuring acceleration with a CFC 3 filter rather than a CFC 60 filter. We believed the CFC 3 filter better represents a wheelchair's dampening characteristic. Since no one objected to this portion of the proposal, we have adopted it as proposed.

3. Maximum Noise Level of Public Use Lifts

We proposed a maximum permissible noise level of 80 dBA in the SNPRM. This level represents the maximum permissible volume of ambient noise allowing for normal communication between two people who are three feet away from each other and exceeds the level of ambient noise at a city bus stop.[9] We sought comment on whether commenters knew of any injuries directly attributable to lift occupant and lift operator being unable to communicate.

Start Printed Page 79423Braun, NMEDA, and Ricon all requested the agency provide a specific distance for measuring lift noise levels. They indicated that measurement point of “lift operator's position” was too vague since the use of a pendant control could allow the lift operator to be several feet away from the lift. Ricon suggested we adopt a measuring point located 55 inches above the platform while the lift is in use. Collins indicated that it knew of no instances in which a lift occupant or bystander was injured because the driver could not hear the passengers. It was, however, aware of instances in which the driver had ignored a passenger during lift operations. The Oregon DOT asked whether NHTSA had taken account of the accumulative effect of additional noise on people with impaired hearing when determining the maximum amount of allowable lift noise. VanHool asked whether the noise level was measured while the vehicle engine was running and whether the maximum noise level was inconsistent with the requirement that the audible alarm produce at least 85 dBA.

We are adopting the requirement as proposed in the SNPRM with slight modification. The purpose of today's requirement is to ensure the lift user and lift operator will be able to communicate. Since lift operators for private use lifts are likely to be the lift user, we believe there is no need to specify a maximum level of noise that the lift may produce. Accordingly, today's requirement only applies to those lifts certified as public-use lifts.

The commenters are correct that the proposed measuring point of the “lift operator's position” was insufficiently objective in the SNPRM to measure maximum noise levels. They are also correct that this uncertainty is exacerbated in systems that use a pendant control, since the location of that control varies based on where the lift operator is standing. Accordingly, we have changed the requirement to state that the maximum noise level will be measured for each operator position specified by the lift manufacturer in the installation instructions. Measurements are taken at the vertical centerline of the face of the control panel 30.5 cm (12 in) out from the face of the control panel. If the lift system uses a pendant control, the vertical measurement point will be at the same location discussed above, but with the control panel in its stowed or stored position, since this places the control at the point closest to the noise source. For controls located outside of the vehicle, the horizontal measurement is 157 cm (62 in) above the ground, which is roughly the same distance from the ground as an adult's ears, while the vertical measurement remains 30.5 cm (12 in) from the face of the control panel.[10]

We did not make any adjustments based on the accumulated effect of noise on individuals with impaired hearing since the lift would only be in use for a short period of time. Additionally, we note that the required 85-dBA audible threshold warning alert exceeds the maximum allowable amount of noise for lift operations. This is intentional. As noted earlier, the audible alert will only sound during lift operations if the threshold area is occupied. Thus, it generally would not be constant throughout the range of lift operations. Additionally, the audible alert should be sufficiently greater than the maximum level allowed for normal lift operations to make it distinguishable.

C. Environmental Resistance

In the SNPRM, we tentatively proposed adopting the SAE requirements for externally mounted lifts. Additionally, we proposed all attachment hardware, regardless of location inside or outside the vehicle, meet the hardware requirements of FMVSS No. 209, Seat belt assemblies, which permits compliance either by passing a salt spray test or by electroplating the components. We sought comment on whether the proposed environmental resistance requirements should be incorporated into the standard.

While the majority of those commenting on this issue supported adding an environmental resistance requirement to the standard, Lift-U maintained that the requirement for electroplating with nickel or a nickel copper alloy was too restrictive. Lift-U also suggested that all lifts, regardless of storage location, meet the SAE requirements for environmental resistance.

Given the strong support among most commenters for an environmental resistance requirement, we are adopting the requirement as proposed in the SNPRM. Both the requirement and test procedure for external components are based on the SAE recommended practice. All attachment hardware, regardless of location, must meet the requirement for attachment hardware specified in FMVSS No. 209. That standard provides for two alternative means of compliance: either by passing the salt spray test or by electroplating with a nickel or nickel/copper coating. We are not extending the SAE-based requirement to hardware located within the occupant compartment of the vehicle because that hardware will not be subjected to environmental conditions any more severe than the hardware regulated by FMVSS No. 209.

D. Platform Requirements

1. Unobstructed Platform Operating Volume

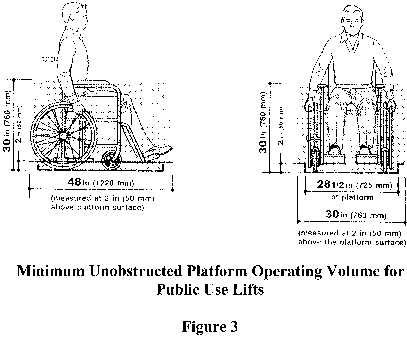

In the SNPRM, we proposed a minimum clear platform width of 724 mm (28.5 in) on the upper surface of the platform, a minimum clear width of 762 mm (30 in) at and between the heights of 51 mm to 762 mm (2 to 30 in) above the platform surface, and a minimum clear length of 122 cm (48 in) above the surface of the platform. No part of the lift or vehicle (except for a required barrier on a platform edge) could intrude into the area above the portion of the platform that would be occupied by a large wheelchair at any point during its operation. No minimum volume was specified for private use lifts, although the vehicle owner's manual insert would have had to specify the unobstructed platform operating volume. We sought comment on whether the suggested approach for private use lifts was appropriate.

The majority of the commenters agreed that it was appropriate to allow lift manufacturers to provide an unobstructed operating volume for private use lifts that was different than that proposed for public use lifts as long as the lift manufacturer disclosed what the unobstructed operating volume was. Collins stated that it could not see any justification for allowing a different size for private use lifts since the lift occupants are the same as those occupants using a commercial lift. APTA and the Michigan DOT averred the width of the upper segment of the unobstructed operating volume for commercial lifts should be increased to 813 mm (32 in) to accommodate scooters.

While Collins is correct that there is no difference in the size of occupants who use personal lifts and occupants who use public lifts, we believe there is a significant difference in lift usage. Personal lifts are generally only used by a single occupant. We expect that occupant will purchase a lift that is suitable for his or her needs. An individual with a large wheelchair or scooter will purchase a lift that accommodates a larger mobility device. An individual with a smaller mobility aid will have no need of a larger lift and may be able to increase his or her vehicle choice by purchasing a lift with a smaller size capacity. In either Start Printed Page 79424instance, the individual using the lift has an input as to which lift to purchase. This is why we believe there is no need to specify a minimum operating volume for personal use lifts as long as the lift manufacturer notifies the lift user of the maximum operating volume.

However, public use lifts are designed to accommodate the needs of several individuals. The transit operator has no way of knowing whether a smaller lift would accommodate the users of the lift. Indeed, it must assume that there will be instances where a larger lift is required to accommodate a particular lift occupant. In these vehicles the question of user choice has been removed. If the transit operators do not purchase sufficiently large lifts, some potential users will be deprived of the opportunity to use the lift.

We recognize the concerns of APTA and the Michigan DOT that the minimum operating volume may be too small to accommodate all mobility devices currently on the market. We too have some concerns that lifts designed to only meet the minimum operating volume may preclude some users from using a public use lift. However, today's requirement is based on existing requirements and the existing design of most lifts. If we were to specify a larger minimum operating volume, we believe a significant number of lifts would have to be redesigned before they could be certified as compliant. We note that nothing in today's rule prevents lift purchasers from procuring lifts with a platform operating volume that is greater than what is required in the standard. We would also expect scooter manufacturers to design their devices in a manner that allows the user to have access to public transportation.

2. Platform Surface Protrusions

For public use lifts, the SNPRM proposed the upper surface of the platform be free from protrusions greater than 6.5 mm (0.25 in) high, and proposed a test procedure for measuring the height of such protrusions. Private use lifts would be allowed to have protrusions up to 13 mm (0.5 in). The proposed limit for private use lifts was less than that required under ADAAG regulations; however, we believed the ADAAG regulations were overly stringent for the private use lifts (which are not subject to ADAAG regulations in any case). For these lifts, we continue to believe that slightly higher protrusions can be allowed for smooth rise without either compromising safety or decreasing the vehicle's accessibility as long as the transition between the platform and the protrusion is gradual.

We received no comments regarding surface protrusions. We continue to believe that allowing protrusions to be between 6.5 mm and 13 mm (0.25-0.5 in) for personal use lifts is consistent with safety for vehicles that will be used by one person with one type of mobility aid. This is also consistent with the transition requirements described in the next section. Accordingly, we are adopting the surface protrusion requirements as proposed in the SNPRM of no more than 6.5 mm on public use lifts and no more than 13 mm on private use lifts.

3. Gaps, Transitions, and Openings

As discussed in the SNPRM, we proposed the openings in the upper surface of the platform be no greater than 19 mm (0.75 in). No vertical surface transition could be more than 6.5 mm (0.25 in) at either the ground or vehicle level and horizontal gaps would be limited to 13 mm (0.5 in). The total allowable rise of any sloped surface (typically ramps or bridging devices) would be limited to 76 mm (3 in). The proposed allowable slope on the portion of the rise between 6.5 mm and 13 mm (0.25 and 0.5 in) above the ground, platform surface, or vehicle surface would be limited to a 1:2 ratio and a 1:8 ratio would be allowed for the portion of the ramp above 13 mm (0.5 in). Gaps between the upper surface of the platform and either the outer barriers or the inner roll stops would be limited to no more than 16 mm (0.625 in) when fully deployed. Gaps would be tested with a 16 x 16 x 102 mm (0.625 x 0.625 x 4.0 in) test block that could not pass through any gaps. Gaps between the lift and edge guards permanently affixed to the ramp could not exceed 13 mm (0.5 in) throughout the range of lift operation. Edge guards that are an integral part of the vehicle could not be more than 6.5 mm (0.25 in) from the platform throughout lift operation.

Lift-U suggested that we limit the restrictions on maximum gap size to the usable platform surface, instead of the entire platform surface, as there may be gaps that are greater than the proposed 19 mm (0.75 in) behind linkages. Since the mobility device or lift passenger does not have access to these portions of the lift, Lift-U argued that there was no need for a maximum size limitation. No other comments were submitted regarding the proposed requirement.

We believe Lift-U's point is well taken. We are only concerned with the area of the platform that coincides with the portion of the platform that may be occupied. Accordingly, we have changed the wording regarding gaps, transitions and openings to indicate that the applicable platform area for this requirement is the area of the platform that coincides with the unobstructed platform operating volume.

4. Platform Deflection

We proposed requiring that the platform angle not deviate from the vehicle floor by more than one degree when the platform is unloaded and by more than three degrees when the platform is loaded. We also proposed platform deflection be tested with a platform load of 272 kg (600 lbs), centrally placed on the lift. The amount of deviation would be measured throughout the lift cycle. This technique is consistent with the one used in the Department of Veterans Administration procurement standard that a specified deflection limit may not be exceeded either before or after loading. The proposed three-degree limit is consistent with both the FTA-sponsored guidelines (sections 2.2.5 and 3.1.3) and the ADAAG (49 CFR 38.23(b)(9)). Testing throughout the lift cycle is also consistent with the FTA requirement that lifts must meet the deflection limit during the entire lift cycle. We requested comment on whether platform deflection should be included in vehicle standard as well as lift standard, limiting the effect of vehicle suspension on lift deflection.

The majority of commenters on this issue indicated that platform deflection relative to the ground is very difficult to measure since the amount of deflection is vehicle-dependent. Collins indicated that heavier lifts will deflect less than those designed for personal use. ATC stated that it had actually measured the level of deflection at ground level on two different buses with the lift loaded with 600 lb of ballast and found the difference in deflection to be minimal. Lift-U noted that some of their lifts are designed to deflect more than one degree to accommodate less-than-ideal road conditions. By design, these lift platforms angle two degrees toward the vehicle centerline when the lift is at the vehicle floor and two degrees away from the vehicle centerline when at ground level.

Lift-U noted that with over 100,000 of these lifts in use, they have an excellent safety record. Accordingly, Lift-U suggested NHTSA adopt a maximum unloaded deflection angle of 1.8 degrees with respect to the vehicle floor with a maximum loaded angle of an additional three degrees with respect to the unloaded position. In both instances, it urged that we not allow a total slope that exceeds a 1:12 ratio. Lift-U maintained that this approach would allow design flexibility and would be Start Printed Page 79425consistent with the ADA requirement for general access to buildings. Prevost noted that the suspension on its vehicles provide a roll angle of one to two degrees when the lift is deployed and loaded.

Because vehicle suspension appears to play only a nominal role in the amount of overall deflection, we have decided to measure platform deflection only as it relates to the vehicle floor. This is what we had proposed in the SNPRM. However, we have made changes to the proposal based on Lift-U's comments. We believe the FTA standard described by Lift-U will adequately protect against excessive deflection. Under the FTA specification, a lift could deflect no more than 4.8 degrees, even when fully loaded. Allowing a maximum deflection of 4.8 degrees, with no more than 1.8 degrees deflection of an unloaded lift (as measured from the vehicle floor reference plane) is consistent with the FTA specification and slightly more stringent than the SAE recommended practice, which specifies a total maximum loaded deflection of 3.6 degrees as compared to its preloaded position. Adopting this slightly more lenient level will obviate the need to make costly changes to existing lift systems.

5. Edge Guards

In the SNPRM we proposed requiring edge guards that were at least 38 mm (1.5 in) high and sought comment on whether any existing passive lifts have edge guards that extend beyond the lowest step riser when the lift is functioning as vehicle steps and whether such a design creates a tripping hazard. We proposed the 38 mm (1.5 in) height because we believed it would be sufficient to deflect the motion of the wheelchair and alert the wheelchair occupant that the wheelchair is at the edge of the platform. Edge guards of this height are required by both the FTA-sponsored guidelines (section 2.2.6.1) and the ADAAG (49 CFR 38.23(b)(5)).

We requested comments on whether any existing lifts have edge guards that extend beyond the lowest step riser when the lift, in a stowed position, converts into vehicle steps, and whether such edge guards create a tripping hazard when the lift is stowed.

Collins stated that it knew of no passive lifts where the edge guard extended below the lowest riser of the steps. Lift-U stated that edge guards on passive lifts should only be required for those portions of the lift that are outside of the vehicle and that any handrails be considered part of the edge guard. It also argued, as did APTA, that the guards should not be required within three inches of the outer edge of the lift. In the same vein, Braun and NMEDA stated that, for personal use lifts, edge guards should not be required on thirty percent of the platform on one side. The basis for both suggestions was that lifts are commonly designed without a continuous edge guard to facilitate the loading and unloading of the lift passenger when space is limited. Braun and NMEDA also alternatively argued for a reduction in minimum height from the proposed 1.5 inches to 0.75 inches.

The edge guard specifications in today's rule have been amended in response to comments. The practice of ending edge guards short of the outer edge of the platform and reducing the length of the edge guards on one side of the platform allows a lift occupant to turn his or her mobility device when space directly in front of the platform is limited. Accordingly, we have decided to require edge guards be present and continuous along the sides of the platform to within 3 inches from the outer platform edge. In many cases this will be less than the 30% reduction common on many lifts. However, we are concerned that allowing up to a 30% reduction in coverage along the side of the platform could compromise wheelchair retention on the lift platform. This is precisely the type of situation we wish to avoid. Some present lift designs offer lifts where a significant portion of the edge guard stows when the lift is at ground level. Other designs feature stowable edge guards that incorporate at least 30% of the entire edge guard. Such systems are permissible under today's rule as long as the edge guard is fully deployed by the time the lift is more than 3 inches above the ground. We believe this will allow those types of lift designs where additional turning space is desirable without compromising the safety of the lift occupant.

Handrails would also be allowed to operate as an edge guard as long as the handrail provides a continuous surface along and adjacent to the side of the platform parallel to the direction of wheelchair movement during loading and unloading. Likewise, as noted in the SNPRM, the interior structure of the stairwell in an over-the-road bus may serve as an edge guard for those lifts. However, we note that the restriction on gaps, transitions and openings discussed above would apply to these surfaces.

We have decided against reducing the minimum height requirement for edge guards on private use lifts. We do not believe a minimum height of one and one-half inches is excessive. Both the FTA and SAE guidelines specify a minimum height of 1.5 inches, and we are unaware of any problems associated with meeting these guidelines. Additionally, commenters failed to provide any rationale as to why a shorter edge guard was needed or how it would adequately protect a lift user.

6. Wheelchair Retention

In the SNPRM, we proposed that lifts be equipped with a wheelchair retention device that can keep a wheelchair upright throughout the range of lift operation and can sustain a direct force of 7,117 N (1,600 lb). We proposed testing the device both dynamically (impact tests) and statically (overload test) since the two tests replicate different conditions. The dynamic impact test was designed to ensure that the wheelchair could not climb a barrier, while the static test measures a restraining device's structural integrity. We proposed running the dynamic impact test by impacting an empty wheelchair into the barrier when the platform is level with the ground. We would run the proposed static test by applying a load against the retention device and then examining it for separation, fracture or breakage. We proposed a separate dynamic test for rotary lifts whereby both barriers are impacted at a point in lift operation between the ground and vehicle floor.

Lift-U and APTA stated that the SNPRM did not clearly indicate whether the wheels of the wheelchair had to remain on the lift platform during the entire test sequence for both tests, or whether they only had to be in contact with the platform at the end of the test. Trolley & Transport suggested that the wheelchair retention device be at least as high as the average armrest, approximately 635-762 mm (25-30 in), in order to prevent a wheelchair occupant from being tipped out of the wheelchair and off the platform. It also recommended that the dynamic test be conducted using the 95th percentile adult male test dummy and 5th percentile adult female test dummy to assure that a wheelchair occupant would not be thrown off the lift even though the wheels of the mobility aid remained on the platform.

Lift-U also indicated that allowing the wheelchair retention test to be performed in one direction when a single loading direction is specified in the owner's manual is contrary to the requirements of the ADA. Braun commented that the compliance tests for the wheelchair retention device should be conducted using the ISO/SAE surrogate wheelchair. NMEDA also advocated that, for personal use lifts, the Start Printed Page 79426outer barrier be required to be fully in position before the lift can be raised or lowered. It stated that this requirement is particularly important for personal use lifts because those systems almost never have a wheelchair securement device to keep the wheelchair on the lift in the absence of an outer barrier. Ricon believed we should mandate the use of an occupant restraint system for the lift as is currently specified in the Canadian Standards Association D-409.

APTA doubted whether any existing lifts, particularly those installed on paratransit vehicles, have retention devices that could withstand the application of 7,117 N (1,600 lbf) without significant redesign. Braun also believes, as does NMEDA, that the static 7,117 N (1,600 lbf) overload test is sufficient for personal use lifts and that no dynamic test is needed. It argues that the dynamic test will require systems, such as belts or taller outboard roll stops, which are cumbersome and generally incompatible with the smaller, personal use lifts.

We have decided to adopt the wheelchair retention device requirement as proposed in the SNPRM. We note that in many instances the retention device will simply be the lift's outer barrier, and, if applicable, the inner roll stop discussed after this section. The test device need not maintain full contact with the lift platform throughout the wheelchair retention dynamic test. It must remain upright at the conclusion of the test.

We have decided against testing the retention device with a 5th percentile adult female test dummy or a 95th percentile adult male test dummy. When developing the wheelchair retention test, we ran the test with the wheelchairs empty and loaded with 102 kg (225 lb) of ballast. The empty wheelchairs were the most likely to climb the barrier. Transport & Trolley is correct that a loaded wheelchair is more likely to tip over the outer barrier; however, we believe the requirement that the wheelchair remain upright at the conclusion of the test should require designs that are unlikely to tip an occupant out of the wheelchair. The only way to guarantee that a wheelchair does not tip over the outer barrier is to require the type of high barrier advocated by Trolley & Transport or to require an occupant restraint system. We are not mandating the use of an occupant restraint system, as specified in the Canadian Standards Association D-409, because we believe such a requirement is unduly design restrictive. Likewise, we have decided against adopting the suggestion that the retention device be as high as a handrail. We are not persuaded that such restrictions on design are warranted. Rather, we believe any device that can meet the applicable static and dynamic tests used to test for compliance will be amply safe. We note that while we are not imposing a requirement that the outer barrier be fully positioned before a lift can be raised or lowered, rather, we are adopting a requirement that the wheelchair retention device must be fully deployed whenever the lift platform is more than 75 mm (3 in) from the ground.

We note that the ADA does not apply to private use lifts. Accordingly, allowing private use lifts without an inner roll stop if the lift manufacturer specifies that rearward loading is required is not inconsistent with the requirements of the ADA.

We have decided against using the ISO surrogate wheelchair because that wheelchair is not powered. Our test procedure requires the technician to maintain power until all wheelchair motion other than the drive wheels has ceased. This requirement is included in the test procedure to determine whether a powered wheelchair is capable of climbing the barrier. Accordingly, it is imperative that we specify a testing device that is power driven.

We do not know why APTA believes none of the lifts currently installed on its' members buses could not meet the 7,117 N (1,600 lbf) static overload test. This test is based on the existing FTA guidelines, which should apply to many of APTA's members. Additionally, no lift manufacturer objected to the force levels proposed in the SNPRM. Absent any evidence that the proposed force level is excessive, we have decided to adopt the static overload test as proposed in the SNPRM.

7. Inner Roll Stop

We proposed in the SNPRM requiring an inner roll stop to prevent a wheelchair from rolling off the platform's inner edge. For arc lifts, i.e., lifts that move in arcing motion from vehicle edge to a distance away from the vehicle edge during operation, this device prevents the lift occupant from falling off the inner edge. For all lifts, it prevents injuries due to pinching and shearing of the occupant's legs or feet between the platform and the vehicle. For elevator lifts, i.e., lifts that move vertically during operation, it is possible for the vehicle wall below the wheelchair lift entry door to perform the function of the inner roll stop. Accordingly, we proposed a two-part requirement for inner roll stops to ensure that the inner roll stop has adequate strength and will be sufficient to prevent pinching of an occupant's feet throughout the range of operations. Tests would be conducted by preventing the wheels of a wheelchair from passing over the inboard edge of the platform when at ground level and by attempting to move the wheelchair toward the roll stop as the lift is operated. We proposed not requiring an inner roll stop on private use lifts as long as the owner's manual specified that rearward loading was required. We requested information whether pinching was possible in rearward-loading lifts.

Braun commented that the compliance tests for the inner roll stop should be conducted using the ISO/SAE surrogate wheelchair. Braun also noted that it was highly unlikely an occupant on a personal lift would be subjected to a pinching risk when using the lift as instructed and in a lift-compatible wheelchair. Lift-U indicated that allowing the inner roll stop test to be performed in one direction when a single loading direction is specified in the owner's manual is contrary to the requirements of the ADA.