-

Start Preamble

Start Printed Page 66434

AGENCY:

Environmental Protection Agency (EPA).

ACTION:

Final rule.

SUMMARY:

EPA is amending specific provisions in the 2009 Final Mandatory Greenhouse Gas Reporting rule to correct certain technical and editorial errors that have been identified since promulgation and to clarify and update certain provisions that have been the subject of questions from reporting entities. These final changes include additional information to better or more fully understand compliance obligations, corrections to data reporting elements so they more closely conform to the information used to perform emission calculations, and other corrections and amendments.

DATES:

The final rule amendments are effective on November 29, 2010. The incorporation by reference of certain publications listed in the final rule amendments are approved by the director of the Federal Register as of November 29, 2010.

ADDRESSES:

EPA has established a docket under Docket ID No. EPA-HQ-OAR-2010-0109 for this action. All documents in the docket are listed on the http://www.regulations.gov index. Although listed in the index, some information is not publicly available, e.g., CBI or other information whose disclosure is restricted by statute. Certain other material, such as copyrighted material, is not placed on the Internet and will be publicly available only in hard copy form. Publicly available docket materials are available either electronically through http://www.regulations.gov or in hard copy at EPA's Docket Center, Public Reading Room, EPA West Building, Room 3334, 1301 Constitution Ave., NW., Washington, DC. This Docket Facility is open from 8:30 a.m. to 4:30 p.m., Monday through Friday, excluding legal holidays. The telephone number for the Public Reading Room is (202) 566-1744, and the telephone number for the Air Docket is (202) 566-1742.

Start Further InfoFOR FURTHER GENERAL INFORMATION CONTACT:

Carole Cook, Climate Change Division, Office of Atmospheric Programs (MC-6207J), Environmental Protection Agency, 1200 Pennsylvania Ave., NW., Washington, DC 20460; telephone number: (202) 343-9263; fax number: (202) 343-2342; e-mail address: GHGReportingRule@epa.gov. For technical information and implementation materials, please go to the Greenhouse Gas Reporting Program Web site http://www.epa.gov/climatechange/emissions/ghgrulemaking.html. To submit a question, select Rule Help Center, followed by Contact Us.

End Further Info End Preamble Start Supplemental InformationSUPPLEMENTARY INFORMATION:

Regulated Entities. The Administrator determined that this action is subject to the provisions of Clean Air Act (CAA) section 307(d). See CAA section 307(d)(1)(V) (the provisions of section 307(d) apply to “such other actions as the Administrator may determine”). These are final amendments to existing regulations. These amended regulations affect owners or operators of certain fossil fuel suppliers, direct emitters of greenhouse gases, and manufacturers of highway heavy-duty vehicles. Regulated categories and entities include those listed in Table 1 of this preamble:

Table 1—Examples of Affected Entities by Category

Category NAICS Examples of affected facilities Adipic Acid Production 325199 Adipic acid manufacturing facilities. Cement Production 327310 Portland cement manufacturing plants. Ferroalloy Production 331112 Ferroalloys manufacturing facilities. Glass Production 327211 Flat glass manufacturing facilities. 327213 Glass container manufacturing facilities. 327212 Other pressed and blown glass and glassware manufacturing facilities. HCFC-22 Production and HFC-23 Destruction 325120 Chlorodifluoromethane manufacturing facilities. Hydrogen Production 325120 Hydrogen manufacturing facilities. Iron and Steel Production 331111 Integrated iron and steel mills, steel companies, sinter plants, blast furnaces, basic oxygen process furnace shops. Lime Production 327410 Calcium oxide, calcium hydroxide, dolomitic hydrates manufacturing facilities. Nitric Acid Production 325311 Nitric acid manufacturing facilities. Phosphoric Acid Production 325312 Phosphoric acid manufacturing facilities. Soda Ash Manufacturing 325181 Alkali and chlorine manufacturing facilities. 212391 Soda ash, natural, mining and/or beneficiation. Titanium Dioxide Production 325188 Titanium dioxide manufacturing facilities. Zinc Production 331419 Primary zinc refining facilities. 331492 Zinc dust reclaiming facilities, recovering from scrap and/or alloying purchased metals. Municipal Solid Waste Landfills 562212 Solid Waste Landfills. 221320 Sewage Treatment Facilities. Suppliers of Coal Based Liquids Fuels 211111 Coal liquefaction at mine sites. Suppliers of Natural Gas and NGLs 221210 Natural gas distribution facilities. 211112 Natural gas liquid extraction facilities. Table 1 of this preamble is not intended to be exhaustive, but rather provides a guide for readers regarding facilities likely to be affected by this action. Table 1 of this preamble lists the types of facilities that EPA is now aware could be potentially affected by the reporting requirements. Other types of facilities than those listed in the table could also be subject to reporting requirements. To determine whether you are affected by this action, you should carefully examine the applicability criteria found in 40 CFR part 98, subpart A or the relevant criteria in the sections related to fossil fuel suppliers, direct emitters of GHGs, and manufacturers of highway heavy-Start Printed Page 66435duty vehicles. If you have questions regarding the applicability of this action to a particular facility, consult the person listed in the preceding FOR FURTHER GENERAL INFORMATION CONTACT section.

Judicial Review. Under section 307(b)(1) of the Clean Air Act (CAA), judicial review of this final rule is available only by filing a petition for review in the U.S. Court of Appeals for the District of Columbia Circuit (the Court) by December 27, 2010. Under CAA section 307(d)(7)(B), only an objection to this final rule that was raised with reasonable specificity during the period for public comment can be raised during judicial review. Section 307(d)(7)(B) of the CAA also provides a mechanism for EPA to convene a proceeding for reconsideration, “[i]f the person raising an objection can demonstrate to EPA that it was impracticable to raise such objection within [the period for public comment] or if the grounds for such objection arose after the period for public comment (but within the time specified for judicial review) and if such objection is of central relevance to the outcome of the rule.” Any person seeking to make such a demonstration to us should submit a Petition for Reconsideration to the Office of the Administrator, Environmental Protection Agency, Room 3000, Ariel Rios Building, 1200 Pennsylvania Ave., NW., Washington, DC 20460, with a copy to the person listed in the preceding FOR FURTHER GENERAL INFORMATION CONTACT section, and the Associate General Counsel for the Air and Radiation Law Office, Office of General Counsel (Mail Code 2344A), Environmental Protection Agency, 1200 Pennsylvania Ave., NW., Washington, DC 20004. Note, under CAA section 307(b)(2), the requirements established by this final rule may not be challenged separately in any civil or criminal proceedings brought by EPA to enforce these requirements.

Acronyms and Abbreviations. The following acronyms and abbreviations are used in this document.

AFPC Association of Fertilizer and Phosphate Chemists

AOD argon-oxygen decarburization

API American Petroleum Institute

ASTM American Society for Testing and Materials

C&D construction and demolition

CAA Clean Air Act

CaO calcium oxide

CBI confidential business information

CEMS continuous emission monitoring system

CFR Code of Federal Regulations

CH4 methane

CKD cement kiln dust

CO2 carbon dioxide

DE destruction efficiency

DOC degradable organic carbon

EAF electric arc furnace

EF emission factor

EIA Energy Information Administration

EPA U.S. Environmental Protection Agency

FR Federal Register

GHG greenhouse gas

HHV higher heating value

ID identification

kg kilograms

lb pound

LNG liquefied natural gas

LMPs lime manufacturing plants

MCF Methane Correction Factor

MgO magnesium oxide

Mscf thousand standard cubic feet

MSW municipal solid waste

MSWLF municipal solid waste landfill

N2 O nitrous oxide

NAICS North American Industry Classification System

NGLs natural gas liquids

NOX nitrogen oxides

NTTAA National Technology Transfer and Advancement Act

OMB Office of Management and Budget

QA/QC quality assurance/quality control

RCRA Resource Conservation and Recovery Act

RFA Regulatory Flexibility Act

SBREFA Small Business Regulatory Enforcement Fairness Act

SWDS solid waste disposal site

TSCA Toxic Substances Control Act (TSCA)

U.S. United States

UMRA Unfunded Mandates Reform Act of 1995

VOD vacuum oxygen decarburization

Table of Contents

I. Background

A. How is this preamble organized?

B. Background on This Action

C. Legal Authority

D. How will these amendments apply to 2011 reports?

II. Final Amendments and Responses to Public Comments

A. Mobile Sources

B. Subpart A—General Provisions

C. Subpart E—Adipic Acid Production

D. Subpart H—Cement Production

E. Subpart K—Ferroalloy Production

F. Subpart N—Glass Production

G. Subpart O—HCFC-22 Production and HFC-23 Destruction

H. Subpart P—Hydrogen Production

I. Subpart Q—Iron and Steel Production

J. Subpart S—Lime Manufacturing

K. Subpart V—Nitric Acid Production

L. Subpart Z—Phosphoric Acid Production

M. Subpart CC—Soda Ash Manufacturing

N. Subpart EE—Titanium Dioxide Production

O. Subpart GG—Zinc Production

P. Subpart HH—Municipal Solid Waste Landfills

R. Subpart MM—Suppliers of Petroleum Products

S. Subpart NN—Suppliers of Natural Gas and Natural Gas Liquids

III. Statutory and Executive Order Reviews

A. Executive Order 12866: Regulatory Planning and Review

B. Paperwork Reduction Act

C. Regulatory Flexibility Act (RFA)

D. Unfunded Mandates Reform Act (UMRA)

E. Executive Order 13132: Federalism

F. Executive Order 13175: Consultation and Coordination With Indian Tribal Governments

G. Executive Order 13045: Protection of Children From Environmental Health Risks and Safety Risks

H. Executive Order 13211: Actions That Significantly Affect Energy Supply, Distribution, or Use

I. National Technology Transfer and Advancement Act

J. Executive Order 12898: Federal Actions To Address Environmental Justice in Minority Populations and Low-Income Populations

K. Congressional Review Act

I. Background

A. How is this preamble organized?

The first section of this preamble contains the basic background information about the origin of these rule amendments. This section also discusses EPA's use of our legal authority under the CAA to collect data under the mandatory GHG reporting rule.

The second section of this preamble describes in detail the rule changes that are being promulgated to correct technical errors, to provide clarification, and to address implementation issues identified by EPA and others. This section also presents a summary and EPA's response to the major public comments submitted on the proposed rule amendments, and significant changes, if any, made since proposal in response to those comments.

Finally, the last (third) section of the preamble discusses the various statutory and executive order requirements applicable to this final rulemaking.

B. Background on This Action

The final Mandatory Reporting of Greenhouse Gases Rule (40 CFR part 98 or Part 98) was signed by EPA Administrator Lisa Jackson on September 22, 2009 and published in the Federal Register on October 30, 2009 (74 FR 56260, October 30, 2009). Part 98, which became effective on December 29, 2009, included reporting of greenhouse gas (GHG) information from facilities and suppliers, consistent with the 2008 Consolidated Appropriations Act.[1] These source categories capture approximately 85 percent of U.S. GHG emissions through reporting by direct emitters as well as suppliers of fossil fuels and industrial Start Printed Page 66436gases and manufacturers of mobile sources.

EPA published a notice proposing amendments to Part 98 to, among other things, correct certain technical and editorial errors that have been identified since promulgation and clarify or propose amendments to certain provisions that have been the subject of questions from reporting entities. The proposal was published on June 15, 2010 (75 FR 33950). The public comment period for the proposed rule amendments ended on July 30, 2010. EPA did not receive any requests to hold a public hearing.

In addition to the notice published on June 15, 2010 (75 FR 33950), EPA published a second proposal on August 11, 2010 (75 FR 48744). The second notice proposed to correct certain technical and editorial errors in Part 98 that were identified since promulgation and clarify or propose amendments to certain provisions that were the subject of questions from reporting entities, primarily to subparts not addressed in the June 15, 2010 proposal. The August 11, 2010 proposal complements the proposal published on June 15, 2010.

C. Legal Authority

EPA is promulgating these rule amendments under its existing CAA authority, specifically authorities provided in CAA sections 114 and 208.

As stated in the preamble to the final Part 98 (74 FR 56260), CAA sections 114 and 208 provide EPA broad authority to require the information mandated by this rule because such data will inform and are relevant to EPA's carrying out a wide variety of CAA provisions. As discussed in the preamble to the initial proposed Part 98 (74 FR 16448, April 10, 2009) CAA section 114(a)(1) authorizes the Administrator to require emissions sources, persons subject to the CAA, manufacturers of process or control equipment, and persons whom the Administrator believes may have necessary information to monitor and report emissions and provide such other information the Administrator requests for the purposes of carrying out any provision of the CAA (except for a provision of title II with respect to manufacturers of new motor vehicles or new motor vehicle engines [2] ). Section 208 of the CAA provides EPA with similar broad authority regarding the manufacturers of new motor vehicles or new motor vehicle engines, and other persons subject to the requirements of parts A and C of title II. For further information about EPA's legal authority, see the preambles to the proposed and final Part 98.[3]

D. How will these amendments apply to 2011 reports?

With two exceptions, we have determined that it is feasible for reporters to implement these changes for the 2010 reporting year because the revisions primarily provide additional clarifications regarding the existing regulatory requirements, generally do not affect the type of information that must be collected and do not substantially affect how emissions are calculated. Our rationale for this determination is explained in the preamble to the proposed rule amendments.[4]

In summary, these amendments, with the two exceptions described below, do not require any additional monitoring or information collection above what was already included in Part 98. Therefore, we have determined that reporters can use the same information that they have been collecting for each subpart to calculate and report GHG emissions for 2010 and submit reports in 2011 under the amended subparts.

The first exception is for reporting CO2 emissions from certain types of decarburization vessels at iron and steel sources under subpart Q. EPA has determined, based on public comments, that it is necessary to allow a delay in reporting from certain decarburization vessels until the 2011 data collection year (and the subsequent annual GHG emissions reports submitted to EPA by March 31, 2012). The delay in implementation was determined to be necessary because although the 2009 final rule was clear that emissions from argon oxygen-decarburization vessels were required to be reported, the inclusion of other types of decarburization vessels was not clear. A more detailed description of the affected decarburization vessels and our rationale is available in Section II.I of this preamble.

The second exception is related to crude oil reporting requirements in subpart MM. We are providing reporters some flexibility in defining a batch of crude oil for purposes of reporting crude oil data for reporting year 2010. A more detailed description of the type of flexibility we are providing and our rationale is available in Section II.R of this preamble. EPA notes that crude oil data does not impact the CO2 calculations for 2010 or for any other reporting year.

II. Final Amendments and Responses to Public Comments

We are amending 40 CFR part 86 to appropriately incorporate the regulatory text into the regulations at 40 CFR 86.1844-01.

In 40 CFR Part 98, we are amending various subparts to correct errors in the regulatory language that were identified as a result of working with affected industries to implement the various subparts of Part 98. We are also amending certain rule provisions to provide greater clarity. The amendments to 40 CFR Part 98 include the following types of changes:

- Changes to correct cross references within and between subparts.

- Additional information to better or more fully understand compliance obligations in a specific provision, such as the reference to a standardized method that must be followed.

- Amendments to certain equations to better reflect actual operating conditions.

- Corrections to terms and definitions in certain equations.

- Corrections to data reporting requirements so that they more closely conform to the information used to perform emission calculations.

- Other amendments related to certain issues identified as a result of working with the reporters during rule implementation and outreach.

The final amendments promulgated by this action reflect EPA's consideration of the comments received on the proposal. The major public comments and EPA's responses for each subpart are provided in this preamble. Our responses to additional significant public comments on the proposal are presented in a comment summary and response document available in Docket ID No. EPA-HQ-OAR-2010-0109.

A. Mobile Sources

1. Summary of Final Amendments and Major Changes Since Proposal

Manufacturers of highway heavy-duty vehicles, as well as manufacturers of highway heavy-duty engines, are subject to GHG reporting requirements. EPA inadvertently omitted the regulatory text covering manufacturers of highway heavy-duty vehicles. We are amending 40 CFR part 86 to correct that error by incorporating the appropriate language into the regulations at 40 CFR 86.1844-01.

2. Summary of Comments and Responses

EPA did not receive any comments on the proposed amendments to 40 CFR Start Printed Page 66437part 86 and is finalizing the amendments as proposed.

B. Subpart A—General Provisions

1. Summary of Final Amendments and Major Changes Since Proposal

We are adding and changing several definitions to subpart A to clarify terms used in other subparts of Part 98. Similarly, we are amending 40 CFR 98.7 (incorporation by reference) to accommodate changes in the standard methods that are allowed by other subparts of Part 98.

We are amending the following definitions in 40 CFR 98.6:

- Carbonate-based mineral.

- Carbonate-based mineral mass fraction.

- Carbonate-based raw material.

- Crude oil.

- Decarburization vessel.

- Gas collection system or landfill gas collection system.

- Mscf.

- Non-crude feedstocks.

We are amending the definitions of “carbonate-based mineral,” “carbonate-based mineral mass fraction,” and “carbonate-based raw material” in order to include barium carbonate, potassium carbonate, lithium carbonate, and strontium carbonate, because these carbonates are consumed in the glass industry subject to subpart N.

We are amending the definition of “crude oil” in 40 CFR 98.6 so that it is consistent with the definition in the Energy Information Administration's (EIA) Definitions of Petroleum Products and Other Terms (Revised January 2010) [5] , with one additional provision to accommodate the needs of this program to ensure complete reporting of petroleum products, including the unique circumstances that have been raised in comments. We are adding a crude oil reporting requirement in subpart MM (40 CFR 98.396 (a)(22)) to accommodate this provision.

We are amending the definition of “decarburization vessel” in 40 CFR 98.6 to include vessels that are used to further refine molten steel with the primary intent of reducing the carbon content of the steel.

We are amending the definition of “gas collection system or landfill gas collection system,” in 40 CFR 98.6 to clarify that the passive vents/flares are not considered part of a landfill gas collection system for purposes of subpart HH, to state that such a system collects gas actively by means of a fan or similar mechanical draft equipment, versus collecting gas passively. Based on a comment received, we are also clarifying that a single landfill may have more than one gas collection system.

We are also amending the definition of “Mscf” in 40 CFR 98.6 to indicate that “Mscf” means thousand standard cubic feet.

We are also amending the definition of “non-crude feedstocks” in 40 CFR 98.6 to remove the phrase “as a feedstock” in order to avoid confusion with the definition of “feedstock.” Under subpart MM, refiners must calculate annual CO2 emissions that would result from the complete combustion or oxidation of each non-crude feedstock. Our intention in subpart MM is to capture all petroleum products and natural gas liquids that enter a refinery to be further refined or otherwise used on site. By removing the term “as a feedstock” from the definition of “non-crude feedstocks” we are aligning the definition to the original intent of subpart MM.

We are also incorporating by reference ASTM D6349-09, “Standard Test Method for Determination of Major and Minor Elements in Coal, Coke, and Solid Residues from Combustion of Coal and Coke by Inductively Coupled Plasma—Atomic Emission Spectrometry” for subpart N.

Major changes since proposal are identified in the following list. The rationale for these and any other significant changes can be found in this preamble or the Response to Comments: Technical Corrections, Clarifying and Other Amendments (see EPA-HQ-OAR-2010-0109).

- In the definitions of “carbonate-based mineral,” “carbonate-based mineral mass fraction,” and “carbonate-based raw material,” adding lithium carbonate and strontium carbonate, as well as the proposed additions of barium carbonate and potassium carbonate.

- Expanding the proposed definition of crude oil to include petroleum products injected into a crude supply or reservoir.

- Narrowing the definition of decarburization vessel to include only vessels for which the primary intent is reducing the carbon content of the steel.

- Incorporating by reference ASTM D6349-09, “Standard Test Method for Determination of Major and Minor Elements in Coal, Coke, and Solid Residues from Combustion of Coal and Coke by Inductively Coupled Plasma—Atomic Emission Spectrometry” for subpart N.

2. Summary of Comments and Responses

This section contains a brief summary of major comments and responses. Several comments were received on this subpart. Responses to additional significant comments received can be found in Response to Comments: Technical Corrections, Clarifying and Other Amendments (see EPA-HQ-OAR-2010-0109).

Comment: One commenter responded to EPA's question regarding whether other carbonates not listed in the proposed definitions are consumed in glass production, and the commenter noted that they consume lithium carbonate and strontium carbonate.

Response: EPA appreciates the clarification and has added these carbonates to the definitions of carbonate-based materials in 40 CFR 98.6 and to Table N-1 to subpart N.

Comment: EPA received several comments on our proposal to amend the definition of crude oil. Two commenters supported the proposed definition of crude oil because it is identical to the definition used for reporting to the Energy Information Administration (EIA) and it will be easier for reporters to calculate and report the same data for both agencies' crude oil reporting requirements. One commenter suggested that EPA expand it even further by adding the word “nitrogen” to describe non-hydrocarbons, referencing atmospheric conditions rather than just atmospheric pressure, removing the requirement that hydrocarbon liquids must be comingled with a crude stream, and including natural gas processing plant liquids captured by gravity separation. Therefore, the commenter did not support using a definition of crude oil that is identical to the definition used by EIA. Two commenters submitted information about situations where a petroleum product is re-injected into a crude supply line or back into a reservoir. One of these two commenters reported that they inject a mixture of products, some of which meet the proposed definition of crude and some of which do not, and specifically requested clarification on how to treat such a mixture with respect to crude oil and petroleum product reporting.

Response: In today's final rule, EPA is retaining the amendatory text proposed for the definition of crude oil and making amendments beyond what was proposed to address the comments received and improve technical accuracy.

EPA agrees with commenters that a definition of crude oil for Part 98 that is identical to the EIA definition makes it easier for refineries to comply with both agencies' reporting requirements. However, EPA considered comments requesting amendments to the crude oil definition in an effort to ensure the definition is technically accurate and to allow for complete reporting.Start Printed Page 66438

EPA considered including natural gas processing plant liquids captured by gravity separation in the crude oil definition, but concluded that doing so would create ambiguity in the regulatory text. EPA has always required natural gas liquids (NGLs) received by the refinery to be reported as non-crude feedstock because the vast majority is being reported by fractionators as product supplied under subpart NN, and EPA does not want these volumes to be double counted across the industry. Because refiners would be unable to physically distinguish NGLs from gravity separation from NGLs reported as product by fractionators under subpart NN, EPA does not concur that such an edit is an improvement to the proposed definition and has not made the suggested change in the definition.

EPA agrees with the comment that specifying atmospheric conditions (temperature and pressure), rather than just atmospheric pressure, is technically more accurate and has made this change in the final definition. This change allows for conditions under which liquids may drop out because of lower temperatures that may not have dropped out in warmer temperatures and atmospheric pressure. EPA has concluded that adding “nitrogen” as an example of non-hydrocarbons does not improve technical accuracy and is not necessary since it is clear that nitrogen is a non-hydrocarbon. Therefore, EPA has not made this change to the final definition.

EPA considered removing the qualification that hydrocarbon liquids must be comingled with a crude stream to meet the crude oil definition and concluded that removing that qualification would create ambiguity. EPA determined that it may be difficult for refineries to distinguish between such hydrocarbon liquids (which commenters suggested should be treated as crude oil) and natural gas liquids or petroleum products (which EPA required be treated as non-crude feedstock) when received and to, therefore, determine how to comply with the rule. EPA has concluded that we cannot delete such text from the crude oil definition unless we specifically seek comment on the impact of such a revision to reporters. Therefore, such an amendment is outside of the scope of this rulemaking.

Finally, EPA is expanding the proposed definition of crude oil to include petroleum products that are received or produced at a refinery and subsequently injected into a crude supply or reservoir by the same refinery owner or operator. EPA is making this addition because, in these situations, petroleum products will be comingled with crude oil to the point of being indistinguishable from crude oil. Whenever a refinery receives the comingled crude oil downstream they will report it as crude oil to EPA. Therefore, this addition is needed to prevent double-counting among reporters under subpart MM. EPA has concluded that the additions to the definition beyond what is used by EIA will only apply to a small minority of refineries that face the unique circumstances presented by commenters and that all other refineries will be able to report to EPA according to the same definition that they use to report to EIA.

With this amendment in place, EPA will need data on the volume injected into a crude supply or reservoir from this small minority of refineries in order to conduct effective verification on the full set of data submitted under subpart MM. Therefore, we are making a harmonizing amendment to subpart MM to require reporting on the volume of any crude oil injected into a crude supply or reservoir under a new paragraph 40 CFR 98.396(a)(22).

Comment: One commenter noted that the Phosphate Mining States Methods Used and Adopted by the Association of Fertilizer and Phosphate Chemists (AFPC) Manual 10th Edition—Version 1.9 had been updated to the version 1.92, which includes a protocol for collecting grab samples of phosphate rock to be tested for chemical composition.

Response: EPA agrees that it is important to allow phosphoric acid facilities to follow the latest standard protocol for grab samples of phosphate rock. In light of this, EPA has finalized requirements to use an industry consensus standard or industry standard practice for collecting grab samples. As an example, the Association of Fertilizer and Phosphate Chemists (AFPC) Manual 10th Edition—Version 1.92 and future versions of that manual would be an acceptable standard.

C. Subpart E—Adipic Acid Production

1. Summary of Final Amendments and Major Changes Since Proposal

We are amending Equation E-1, Equation E-2 and Equation E-3 in 40 CFR 98.53. First, we are amending these equations so that the calculation equations are internally consistent. Currently, the equations do not correctly address situations in which a facility has more than one production unit or process line with separate N2 O control or abatement technology on the separate production units or process lines, and the technologies are not operated 100 percent of the time. In these circumstances, the current equations will not provide an accurate calculation of N2 O emissions. We are amending the equations so that emissions are calculated separately for each production unit or process line (or groups of units or lines) that has a separate control or abatement technology, and then the emissions for all such units or lines are summed to determine the overall N2 O emissions for the facility. For consistency with these amendments, we are also amending 40 CFR 98.54(a), 98.56(j), and 98.57(c) for monitoring and QA/QC, reporting, and recordkeeping, respectively.

We are amending 40 CFR 98.53(b)(1) to address performance testing when a group of adipic acid production units share a common abatement technology or emission point.

We are amending Equation E-3 of subpart E to accommodate N2 O abatement technology located after the emission test (sampling) point and re-designating it as Equation E-3a of subpart E. There are three ways in which abatement technology can be employed. Equation E-3a of subpart E is for one N2 O abatement technology. We are amending Equation E-3a of subpart E further so that the annual adipic acid produced by adipic acid unit “z” (Pz) is used rather than annual adipic acid produced by unit(s) for which N2 O abatement technology “N” is operating (Pa,N). Also, the summation was removed.

We are adding Equation E-3b of subpart E to accommodate multiple N2 O abatement technologies in series and we are adding Equation E-3c of subpart E to accommodate multiple N2 O abatement technologies in parallel. We are also adding a new Equation E-3d of subpart E for facilities that do not have any N2 O abatement technology located after the test (sampling) point.

We are adding Equation E-4 of subpart E to sum the emissions from Equations E-3a through E-3d of subpart E for each adipic acid production unit “z”.

We are amending the language in 40 CFR 98.54(a)(3) and 98.56(k) regarding the Administrator approved alternative method to clarify that this alternative method is for determining N2 O emissions rather than N2 O concentration. Also, we are amending the language in 40 CFR 98.54(a)(1), (e) and (f) to clarify the location of the test (sampling) point used for the performance test and to clarify that the performance test should be conducted when the process is operating normally. As promulgated, the language can be Start Printed Page 66439misconstrued that EPA is requiring the facility to shut down any N2 O abatement technology during the performance testing. This was not intended because many, if not all, of the N2 O abatement technologies in use must be operated at all times that the adipic acid facility is operated to control emissions of NOX in order to comply with state and federal regulations limiting NOX emissions. The amendments clarify that testing can occur before or after N2 O abatement technology as long as the destruction efficiency of the N2 O abatement technology is properly accounted for and adipic acid production is quantified while abatement equipment is operating. Finally, we are clarifying under 40 CFR 98.57(f) that facilities should retain records of all data collected during performance tests, not just the calculated emission factor. This clarification is consistent with the general recordkeeping requirements in 40 CFR 98.3(g)(2)(ii).

Major changes since proposal are identified in the following list. The rationale for these and any other significant changes can be found in this preamble or the Response to Comments: Technical Corrections, Clarifying and Other Amendments (see EPA-HQ-OAR-2010-0109).

- Language was added to 40 CFR 98.53(b)(1) to address performance testing when multiple adipic acid production units exhaust to a common emission point.

- Changed the emission factor in Equation E-1 of subpart E from EFN2O,N to EFN2O,z to eliminate confusion.

- Changed the description of the emission factor, EFN2O,z from “Average facility-specific N2 O emission factor for each adipic acid production unit (lb N2 O generated/ton adipic acid produced)” to “Average facility-specific N2 O emission factor for each adipic acid production unit “z” (lb N2 O/ton adipic acid produced).”

- Changed the terms “waste gas stream” and “air stream” to “vent stream” at 40 CFR 98.53(b)(1) and 98.53(g)(1).

- Edited Equation E-1 and Equation E-3a of subpart E to include changes above.

- Added Equation E-3b, Equation E-3c, Equation E-3d and Equation E-4 of subpart E.

2. Summary of Comments and Responses

This section contains a brief summary of major comments and responses. Several comments were received on this subpart. Responses to additional significant comments received can be found in Response to Comments: Technical Corrections, Clarifying and Other Amendments (see EPA-HQ-OAR-2010-0109).

Comment: One commenter raised the issue that there are situations where multiple adipic acid production units exhaust to a common abatement technology or emission point and should be addressed during the performance test.

Response: EPA has added language at 40 CFR 98.53(b)(1) to address performance testing for a group of adipic acid production units exhausting to a common abatement technology or emission point and for other possible situations that were not accurately addressed by the proposed Equation V-3a of subpart V (abatement technologies used in series and backup abatement technologies operated periodically. We are aware of at least one facility where multiple units exhaust through a common abatement technology.

Comment: One commenter suggested that the subscript letter “N” in the term EFN2O,N used in Equation E-1 of subpart E be explained and changed to avoid confusion with the term “N” in Equations E-2 and E-3a. The commenter also suggested that the word “generated” be struck from the definition of EFN2O,N in Equation E-1 of subpart E to reflect that the emission factor may now be determined either before or after abatement. If measured after abatement, EFN2O,N represents the controlled emission rate instead of the amount ofN2O generated. The commenter suggested a similar change to Equations E-3a and E-3b of subpart E where the terms EFN2O,N and EFN2O respectively, are used.

Response: EPA agrees that the subscript letter “N” in the term EFN2O,N used in Equation E-1 of subpart E could be confused with the term “N” used in Equations E-2 and E-3a of subpart E. Therefore, the subscript “N” has been changed to subscript “z” in Equation E-1 of subpart E. EPA also agrees that EFN2O,N represents the controlled emission rate instead of the amount ofN2O generated, if the test point is located after the abatement technology. Therefore, the definition of EFN2O,z has been revised to be the average facility-specificN2O emission factor for each adipic acid production unit “z”, in units of lb NN2O/ton adipic acid produced.

EPA also removed the word “generated” in Equations E-3a and E-3b of subpart E for the definitions of the terms EFN2O,N and EFN2O, respectively.

Comment: One commenter agreed with the proposed amendments to correctly calculate emissions in which an abatement technology is not operated 100 percent of the time. The commenter requested that additional changes be made to Equation E-3a in 40 CFR 98.53(g)(1). The commenter suggested the use of Pa (annual adipic acid produced for unit a) instead of PaN (annual adipic acid produced by unit(s) for whichN2O abatement technology “N” is operating), and noted that the summation over the range of 1 to N should include only the term (1-(DFN*AFN)), to accurately represent the effect of multiple abatement devices on each unit.

Response: EPA agrees that annual adipic acid produced from unit “z” (Pz) should be used rather than annual adipic acid produced by unit(s) for whichN2O abatement technology “N” is operating (Pa,N). These changes have been made in the final rule.

D. Subpart H—Cement Production

1. Summary of Final Amendments and Major Changes Since Proposal

We are amending 40 CFR 98.84(b) to correct the most recent ASTM standard, to ASTM C114-09 rather than C114-07, for determining the weight fraction of magnesium oxide (MgO) and calcium oxide (CaO) in clinker. In addition we have learned through questions from reporters, that for some facilities it is more efficient to sample clinker for the weight fraction of total MgO and CaO as it exits the kiln rather than from bulk storage. Some facilities do perform this analysis on clinker on a daily basis. We are amending the rule to allow facilities the option to determine a monthly value based on the arithmetic average of the daily samples.

Through reporters we have also learned that facilities use direct measurement in conjunction with other factors (e.g., kiln feed) to determine clinker production. These procedures are verified periodically for accuracy. We are amending 40 CFR 98.84(d) to allow facilities to use these existing procedures for measuring clinker produced and verify those on a monthly basis. Facilities are already required to measure clinker on a monthly basis. Concurrent with this change, we are amending 40 CFR 98.86(b) so that facilities that do not estimate combined process and combustion emissions using continuous emission monitoring systems (CEMS) will be required to report the kiln specific feed-to-kiln ratios used to calculate clinker produced for EPA verification of emissions associated with clinker production. For consistency, we are clarifying 40 CFR 98.84(e) to allow similar flexibility in determination of cement kiln dust produced.

Further, we understand from facilities' questions that an analysis of the organic carbon contents of raw materials could be determined from a composite sample of the kiln feed or from sampling each raw material in the Start Printed Page 66440kiln feed depending on the existing sampling methods and raw material storage procedures at the facility. We are amending the calculation and monitoring procedures in 40 CFR 98.83(d)(3) and 98.84(c) to allow facilities the option to use either sampling procedure for estimating carbon dioxide (CO2) emissions from raw materials.

We are also correcting and clarifying the recordkeeping requirements under 40 CFR 98.87(a) and (b) for facilities with CEMS and for facilities without CEMS. In Part 98, the recordkeeping requirements listed under 40 CFR 98.87(a)(1) and (a)(2) should have been listed under 40 CFR 98.87(b). Facilities using CEMS to estimate combined process and combustion CO2 emissions from kilns do not need to calculate process emissions using the clinker based emissions methodology provided in Subpart H and, therefore, would not have the relevant records requested in 40 CFR 98.87(a)(1) and (a)(2).

Major changes since proposal are identified in the following list. The rationale for these and any other significant changes can be found in this preamble or the Response to Comments: Technical Corrections, Clarifying and Other Amendments document (see EPA-HQ-OAR-2010-0109).

- Clarifying the cement kiln dust (CKD) monitoring requirements in 40 CFR 98.84(e);

- Changing cement production reporting requirements under 40 CFR 98.86 to require annual, facility-wide cement production instead of monthly, kiln-specific cement production; and

2. Summary of Comments and Responses

This section contains a brief summary of major comments and responses. Several comments were received on this subpart. Responses to additional significant comments received can be found in Response to Comments: Technical Corrections, Clarifying and Other Amendments document (see EPA-HQ-OAR-2010-0109).

Comment: One commenter expressed concern that the monthly verification of the feed-to-clinker ratio, required under 40 CFR 98.94(d), is unduly burdensome. The commenter suggested that EPA change subpart H to require quarterly verification instead of monthly.

Response: Because subpart H requires cement manufacturers to report clinker production on a monthly basis, we are requiring facilities that estimate clinker production using a feed-to-clinker ratio to verify the accuracy of that ratio also on a monthly basis. We provided cement manufacturers the option to use a feed-to-clinker ratio instead of direct clinker measurement to provide flexibility and consistency with current industry practices. We note the commenter's concern regarding the burden of monthly verification. However, other industry comments generally support this requirement.

Comment: One commenter stated that the CKD measurement requirements under 40 CFR 98.84(e) should be revised to be consistent with the clinker measurement requirements under 40 CFR 98.84(d). Specifically, 40 CFR 98.84(d) allows facilities to determine monthly clinker quantities by either reconciling weigh hopper or belt weigh feeder measurements against inventory measurements, or by direct weight measurement of raw feed and applying a feed-to-clinker ratio. Meanwhile, 40 CFR 98.84(e) requires facilities to determine quarterly CKD quantities by direct weight measurement. The commenter points out that the CKD quantity has a lesser impact on CO2 emission calculations than the clinker quantity. Therefore, the rule should not have more stringent measurement requirements for CKD than for clinker. The commenter also states that direct weight measurement devices should not be required to be installed if they are currently not being utilized at the facility, and requests that facilities be permitted to use the same methods currently in place for accounting purposes to determine the quantity of CKD not recycled to the kiln.

Response: The rule currently allows for the type of flexibility that the commenter is requesting. The rule lists direct weight measurement as an example technique that may be used; however, the examples provided in the rule are not an exhaustive list. Facilities should determine the quantity of CKD not recycled to the kiln for each kiln using the same plant techniques used for accounting purposes. We have revised the language in 40 CFR 98.84(e) to clarify this flexibility.

Comment: Two commenters noted that reporting requirements in 40 CFR 98.86(a)(2) and 98.86(b)(3) require cement manufacturers to report monthly cement production from each kiln at the facility. The commenters pointed out that cement kilns produce clinker—not cement. The clinker from each cement kiln is subsequently sent to a mill and pulverized into a fine powder, and mixed with other ingredients to produce cement. Plants that operate multiple kilns may combine the clinker from all kilns and store the combined clinker before feeding it to the cement mill. Because of the variability of the amount of clinker produced by different kilns, and the varying methods of storage, the commenters proposed that EPA require cement manufacturers to report the total quantity of cement produced by the facility on an annual rather than monthly, kiln-specific basis.

Response: EPA agrees with the commenter that the requirements in 40 CFR 98.86(a)(2) and 98.86(b)(3) are inconsistent with cement plant manufacturing practices, and should not be required on a kiln-specific basis. In addition, we agree that due to the variations in storage time between clinker production and cement production, cement production data are not needed on a monthly basis. This reporting requirement was added for verification of reported emissions, not calculating emissions. Therefore, we have revised the rule to require facilities to report cement production on an annual, facility-wide basis.

E. Subpart K—Ferroalloy Production

1. Summary of Final Amendments and Major Changes Since Proposal

We are amending 40 CFR 98.112(a) to be consistent with the requirement described in 40 CFR 98.113(d) to calculate methane (CH4) emissions from an electric arc furnace (EAF) used for the production of all ferroalloys for which an applicable CH4 emission factor is provided in the rule. These alloys and the associated CH4 emission factors are listed in Table K-1 to subpart K. Subpart K in Part 98 contained calculation and reporting procedures for quantifying process CH4 emissions from all ferroalloys listed in Table K-1 to subpart K, but CH4 was inadvertently not included in the GHGs to Report section.

We are also amending the introductory language for 40 CFR 98.113 to clarify the applicability of the procedures for calculating CO2 and CH4 emissions in that section. Finally, we are amending the language in 40 CFR 98.116 to clarify that the data reporting requirements in 40 CFR 98.116(b) are for each EAF and those in 40 CFR 98.116(d)(1) and (e)(1) are for any ferroalloy product identified in 40 CFR 98.110. We are also amending 40 CFR 98.116(d) to correct an incorrect cross-reference to 40 CFR 98.36.

2. Summary of Comments and Responses

EPA did not receive any comments on the proposed amendments to subpart K and is finalizing the amendments to this subpart as proposed.Start Printed Page 66441

F. Subpart N—Glass Production

1. Summary of Final Amendments and Major Changes Since Proposal

We are amending subpart N to add CO2 emission factors to Table N-1 to subpart N for barium carbonate, potassium carbonate, lithium carbonate, and strontium carbonate. These raw materials were not included in Part 98, but EPA has since learned that they are also used by the glass industry. EPA is also amending 40 CFR 98.144(b) to allow for an additional method for determining the carbonate mineral mass fraction of raw materials used in glass production. Specifically, in addition to ASTM D3682-01, reporters can also use ASTM D6349-09, “Standard Test Method for Determination of Major and Minor Elements in Coal, Coke, and Solid Residues from Combustion of Coal and Coke by Inductively Coupled Plasma—Atomic Emission Spectrometry.” We are also amending the introductory language to 40 CFR 98.146(a) to correct an incorrect cross-reference to 40 CFR 98.36 and to clarify in 40 CFR 98.146(a)(2) that reporting of glass production is by furnace and from all furnaces combined, consistent with the calculation methods. We are amending 40 CFR 98.146(b)(7) and (9) to correct typographical errors.

Major changes since proposal are identified in the following list. The rationale for these changes can be found in this preamble.

- Added an emission factor for lithium carbonate.

- Added an emission factor for strontium carbonate.

- Removed the requirement for analysis by an “independent certified laboratory.” When the final subpart N was published on October 30, 2009, EPA agreed with commenters that analyses do not have to be performed by an independent certified laboratory, but this language inadvertently remained in subpart N.

2. Summary of Comments and Responses

This section contains a brief summary of major comments and responses. One comment letter was received on this subpart.

Comment: One commenter asked that emission factors for lithium carbonate and strontium carbonate be added to subpart N, in addition to those being added for barium carbonate and potassium carbonate.

Response: EPA has added these two compounds to the final subpart N. EPA was not previously aware of use of these carbonates in glass production in the United States during the initial proposal of the rule. While less common, these carbonates are used in glass production to add different properties to glass products and EPA therefore agrees that these emission factors should be included in the final rule.

G. Subpart O—HCFC-22 Production and HFC-23 Destruction

1. Summary of Final Amendments and Major Changes Since Proposal

We are amending 40 CFR 98.154(k), the requirement to monitor HFC-23 emitted from process vents, to refer to Equation O-7 of subpart O rather than Equation O-6 of subpart O. In 40 CFR 98.154(k), (l), and (o) and in 40 CFR 98.156(b), we are amending the language so that the term “destruction device” is used rather than the narrower term “thermal oxidizer.”

We are amending the reporting requirements in 40 CFR 98.156(c) and (d) to clarify that only facilities that are required to recalculate the destruction efficiency of their destruction device under 40 CFR 98.154(l) must report the flow rate of HFC-23 being fed into the destruction device, the flow rate at the outlet of the destruction device, and the emission rate of the device. In addition, such facilities will be required to report the newly calculated DE of the device, the HFC-23 concentration measurement used in the DE calculation, and whether 40 CFR 98.154(l)(1) or (l)(2) was used for the calculation. Under these two paragraphs, other HFC-23 destruction facilities will be required to report only the results of their annual measurement of the HFC-23 concentration at the outlet of the destruction device.

We are amending the reporting requirements in 40 CFR 98.156(e) to clarify that the one-time report for HFC-23 destruction facilities is due by March 31, 2011 or within 60 days of commencing HFC-23 destruction. The amendment was necessary because it was not clear when the one-time report must be submitted. The amendment will make the due date in 40 CFR 98.156(e) consistent with the due date for a similar report required in Subpart OO.

In general, these amendments to the reporting requirements for HFC-23 destruction facilities make them consistent with the monitoring requirements for these facilities. The due dates for the one-time report are consistent with those elsewhere in Part 98 for the source categories that are required to begin monitoring in 2010.

2. Summary of Comments and Responses

EPA did not receive any comments on the proposed amendments to subpart O and is finalizing the amendments to this subpart as proposed.

H. Subpart P—Hydrogen Production

1. Summary of Final Amendments and Major Changes Since Proposal

We are amending the definition of the source category in 40 CFR 98.160(c) to clarify that hydrogen production facilities located within other facilities are also included in the source category if they are not owned by, or under the direct control of, the other facility's owner and operator. This clarification was necessary to correct a misunderstanding that the original rule text limited the source universe to hydrogen production facilities located within petroleum refineries.

Broadly, we are amending subpart P to remove several references to “process” CO2 emissions. EPA received information from industry indicating that the use of the term “process” in the context of calculating and reporting CO2 emissions resulted in confusion in differentiating between process and combustion emissions. We are clarifying the text in the rule by removing references to the term “process” from the rule language.

We are removing the requirements in 40 CFR 98.162(b) for owners or operators to report CO2, CH4 and N2 O combustion emissions from each hydrogen production process unit using the emissions calculation methods in subpart C. This provision results in double counting of combustion-related emissions from hydrogen production process units, as these combustion emissions are already accounted for when following the calculation methods in 40 CFR 98.163(a) or (b). CO2 emissions will still be reported under 40 CFR 98.162(a) using the procedures in 40 CFR 98.163(a) or 98.163(b).

We are also amending language describing the calculation of GHG emissions from gaseous, liquid and solid fuels and feedstocks in 40 CFR 98.163. The clarified language specifies that each gaseous, liquid or solid fuel and feedstock will need to be calculated based on its respective equations detailed in the rule language. This removes the concern that the language was unclear as to which fuel and feedstock stream should be used to calculate CO2 emissions.

Lastly, we are amending 40 CFR 98.166(c) to strike “quarterly” and “kg” (kilogram). Some facilities subject to subpart P may also be subject to subpart PP—Suppliers of Carbon Dioxide. Quarterly reporting of CO2 quantities (in kilograms) was not consistent with subpart PP.Start Printed Page 66442

2. Summary of Comments and Responses

All comments received on the proposed amendments to subpart P were supportive and EPA is finalizing the amendments to this subpart as proposed.

I. Subpart Q—Iron and Steel Production

1. Summary of Final Amendments and Major Changes Since Proposal

We are amending the subpart Q requirements regarding emissions from flares to clarify the requirements and correct certain deficiencies in the rule pertaining to flares burning off-gases from argon-oxygen decarburization (AOD) and other decarburization processes. Section 98.172(b) of Part 98 required reporting of CO2 emissions from flares using procedures from subpart Y (Petroleum Refineries), without distinguishing flares burning off-gases from AOD or other decarburization processes from other types of flares.

The referenced equations in subpart Y and the further instructions in 40 CFR 98.172(b) are applicable to estimating emissions from burning coke oven gas or blast furnace gas, but are not applicable for estimating emissions from flares burning the off-gases from AOD or other decarburization processes. We are, therefore, amending the language in 40 CFR 98.172(b) to clarify that for subpart Q facilities, flare emissions must be estimated for flares burning blast furnace gas or coke oven gas. Similarly, we are amending the introductory text in 40 CFR 98.175 to specify that the missing data procedures in subpart Y (Petroleum Refineries) at 40 CFR 98.255(b) must be followed for flares burning coke oven gas or blast furnace gas. We are also amending the introductory text for the data reporting requirements in 40 CFR 98.176 to include flares burning coke oven gas or blast furnace gas.

Subpart Q in Part 98 also referenced incorrect equations from subpart Y. We are amending and correcting the references in 40 CFR 98.172(b) to the subpart Y flare equations. Equations Y-2 and Y-3 of subpart Y are the correct equations; the promulgated subpart Q of subpart Q incorrectly referenced Equation Y-1 of subpart Y.

We are amending the reporting requirements in 40 CFR 98.176(e)(3) to clarify that fuel consumption needs to be reported separately for each type of fuel and other process input and output material. We are also adding paragraphs (g) and (h) to 40 CFR 98.176. Paragraph (g) requires facilities to report the annual amount of coal charged to coke ovens because it is used to estimate CO2 emissions from coke pushing. Paragraph (h) incorporates the same reporting requirements specified in 40 CFR 98.256(e) of subpart Y (Petroleum Refineries) for flares burning coke oven gas or blast furnace gas.

We are amending the recordkeeping requirements in 40 CFR 98.177(d) to clarify the units and processes for which annual operating hours need to be recorded.

We are also amending the requirements in the promulgated rule to estimate GHG emissions from AOD vessels to clarify that they also apply to any other type of vessel used with the primary intent of removing carbon from molten steel (decarburization), such as vacuum oxygen decarburization. Because of the clarification noted above to include all types of decarburization vessels used primarily to remove carbon, we are replacing the term “argon-oxygen decarburization vessels” with the term “decarburization vessels” throughout subpart Q and replacing the definition of “argon-oxygen decarburization vessels” with a definition for “decarburization vessels” in order to maintain reporting of the CO2 emissions from these vessels.

In response to comments, we are clarifying the definition of “decarburization vessels” to include only those decarburization vessels, such as AOD and vacuum oxygen decarburization vessels, used with the primary intent of removing carbon from the steel. We are also delaying the reporting of GHG emissions from decarburization vessels that are not AOD vessels until reports submitted in 2012, instead of requiring reporting with the first reports submitted to EPA in March 2011.

Major changes since proposal are identified in the following list. The rationale for these and any other significant changes can be found in this preamble or the Response to Comments: Technical Corrections, Clarifying and Other Amendments document (see EPA-HQ-OAR-2010-0109).

- Clarifying the definition of “decarburization vessels” to include only those decarburization vessels used with the primary intent of removing carbon from the steel.

- Delaying the reporting of GHG emissions from decarburization vessels that are not AOD vessels until reports submitted in 2012.

2. Summary of Comments and Responses

This section contains a brief summary of major comments and responses. Several comments were received on this subpart. Responses to additional significant comments received can be found in Response to Comments: Technical Corrections, Clarifying and Other Amendments document (see EPA-HQ-OAR-2010-0109).

Comment: We received three comments on our proposal to clarify the definition of decarburization vessels to include all decarburization vessels rather than just argon-oxygen decarburization (AOD). Two commenters noted that the proposal was not merely a technical correction or clarification, but was instead a substantive change to subpart Q as promulgated. According to the commenters, the new definition of decarburization vessel, which includes a list of the covered processes and the phrase “or other decarburization vessels,” was too broad and inclusive. The commenters noted that most steel plants, whether integrated or electric arc furnace producers, employ several different kinds of refining processes to improve the quality of the steel produced, and some of these refining processes, such as AODs, are primarily intended to reduce carbon. However, the commenters stated that other processes, such as vacuum degassing, electro-slag remelting, and vacuum-arc remelting, are primarily intended to reduce dissolved gases such as hydrogen, nitrogen, and oxygen in the molten steel, and carbon reduction is only incidental. According to the commenters, making these processes subject to subpart Q would require facilities to make numerous adjustments to their monitoring plans and conduct additional sampling. For these reasons, the commenters believe that the proposed amendment would add significant new requirements and represent a substantive change rather than being merely a clarification. One commenter argued that the time and effort to verify GHG emissions from vacuum degassing would be burdensome, estimating that it would increase the resources needed to comply with subpart Q by 50 percent. The commenter stated that the added burden of data collection, measurements, recordkeeping, and reporting of these emissions is not justified by the addition of vacuum degassing and other refining operations to the reporting requirements.

Two of the commenters estimated that the additional processes included in the proposed amendment contribute “substantially less than 1 percent” of the emissions from the sector. Another commenter estimated they contributed only 0.02 percent of the emissions. The same commenter argued that because these emissions are relatively Start Printed Page 66443insignificant and would be extremely difficult to quantify for reporting purposes, they should continue to be excluded from reporting obligations. The commenter also rejected the rationale that emissions from all decarburization vessels should be reported because EPA is also proposing to limit reporting of emissions from flares to those burning coke oven gas or blast furnace gas only (an amendment that the commenter supports), which would obviate reporting of vacuum degasser flare emissions. The commenter estimated that the emissions are so low they would be difficult to detect, and measuring such emissions through either the carbon-mass balance approach or a site-specific emission factor would be burdensome and potentially infeasible. The commenter concluded that EPA has not provided a rational basis for inclusion of decarburization vessels within the GHG Reporting Program.

Two commenters recommended that if EPA proceeds by adding a definition for “decarburization vessel,” the definition should be revised. One commenter suggested that the definition be clarified such that it includes only vessels for which the primary purpose is decarburization. The other commenter asked that it be revised to read “any vessel used to further refine molten steel with the primary intent of reducing carbon content of the steel that also requires flaring the off-gas to oxidize CO to CO2.”

All three commenters stated that if EPA chooses to include all decarburization vessels as proposed, they should not be included in the reports submitted to EPA in 2011. Two commenters explained that making this change retroactive to data collection in 2010 is untenable because companies were obligated to develop comprehensive GHG Monitoring Plans in early 2010 and to begin recordkeeping in January 2010 in order to be able to report for the entire 2010 reporting year by March 2011.

One commenter stated that by expanding the decarburization vessel definition in Subpart Q to include vacuum degassing and other refining operations beyond AODs, facilities with these operations will need to make adjustments to their monitoring plans, conduct additional sampling of inputs and outputs for these operations, make programmatic modifications to tracking software, and re-train employees. The commenter claimed that it will be impossible to collect the necessary samples of steel and dust or sludge and perform analyses representative of the months that have elapsed since the beginning of 2010 in order to perform a mass balance, and it is also unrealistic to expect companies to consider the option of establishing a site-specific emission factor for these units because of all of activities that would be required to perform testing. The commenter recommended that EPA follow the course set in its July 12, 2010 final rule notice adding four new source categories to Part 98 (75 FR 39735). The commenter said that EPA recognized in that notice that it would be unrealistic to require those operations to report emissions for 2010 and made these new rules effective with the data collection in 2011.

Two commenters recommended that if EPA proceeds with the proposed changes, those requirements should be effective no sooner than 2011 and should be reportable in March 2012. One commenter argued that by amending a rule to include data acquisition and management after a reporting period has already begun is arbitrary and capricious and will significantly add to the burden the regulated community faces when attempting to collect meaningful data. The commenter stated that any such amendment should be prospective in nature and not impact calculations and sampling already underway.

Response: After consideration of these comments, we agree that the proposed new definition of “decarburization vessels” was too broad and would include certain steel refining processes that were not intended (i.e., those whose primary purpose is not removal of carbon). Some of the additional processes cited by the commenters have a primary purpose to remove dissolved gases, and although some carbon may be incidentally removed, the CO2 emissions from these processes are a small percent of total GHG emissions from iron and steel making. Because the change in carbon content of the steel is so small, it is difficult to accurately quantify the emissions by a carbon balance, and it is problematic to measure them because of the sampling and other difficulties mentioned by the commenters. Consequently, we are revising the definition of “decarburization vessels” to include those for which the primary purpose is removal of carbon, including but not limited to AOD and vacuum oxygen decarburization (VOD). We are not adding the suggested revision that the definition should include only those decarburization vessels equipped with flares because not all AOD and VOD vessels are equipped with flares. The revised definition makes the amendment a technical clarification that is more consistent with the final rule as originally promulgated.

We also agree that additional time would be required to gather the data to report emissions from decarburization vessels other than AOD vessels, and we are amending the reporting requirements so that these emissions are reported beginning in March 2012 for the year 2011. However, the final amendments will not require a delay in the reporting period for AOD vessels because facilities with AOD vessels have known since the original promulgation of subpart Q that these decarburization vessels would be included in the reporting for 2010.

J. Subpart S—Lime Manufacturing

1. Summary of Final Amendments and Major Changes Since Proposal

We are amending the cross reference to 40 CFR 98.193(b)(1) in the introductory language to 40 CFR 98.195; it incorrectly referenced 40 CFR 98.193(b)(2).

We are also amending the terminology used throughout subpart S to clarify whether the calculation and reporting requirements are referring to calcined byproducts and waste materials by adding the word “calcined” to the lime byproduct and waste terminology, as needed. We are also amending the terminology in the subpart to clarify when the calculation and reporting requirements apply to lime products that are produced at the facility.

2. Summary of Comments and Responses

EPA did not receive any comments on the proposed amendments to subpart S and is finalizing the amendments to this subpart as proposed.

K. Subpart V—Nitric Acid Production

1. Summary of Final Amendments and Major Changes Since Proposal

We are amending 40 CFR 98.223 and 98.224 to clarify how N2 O emissions are to be measured if a facility has an N2 O abatement device. The first amendment clarifies the location of the test (sampling) point used for the performance test in several paragraphs in 40 CFR 98.223. As promulgated, the language could be misconstrued to require the nitric acid facility to shut down any N2 O abatement technology during the performance testing. This was not the intention as many, if not all, of the N2 O abatement technologies in use must be operated at all times that the nitric acid facility is operated to control emissions of NOX in order to comply with state and federal regulations limiting NOX emissions. The Start Printed Page 66444amendments will clarify that testing can occur before or after N2 O abatement technology as long as the testing properly accounts for destruction efficiency.

We are amending Equation V-3 of subpart V to accommodate N2 O abatement technology located after the emission test (sampling) point, and re-designating it as Equation V-3a of subpart V. Equation V-3a is also corrected so that the term on the left-hand side of the equation is changed from EFN2Ot to EN2Ot.

There are three ways in which abatement technology can be employed. Equation V-3a of subpart V is for one N2 O abatement technology. We are adding Equation V-3b of subpart V to accommodate multiple N2 O abatement technologies in series and we are adding Equation V-3c of subpart V to accommodate multiple N2 O abatement technologies in parallel.

We are also including a new Equation V-3d of subpart V for facilities that do not have N2 O abatement technology located after the test (sampling) point.

In addition, we are clarifying in 40 CFR 98.223 that the annual performance test must be conducted for each nitric acid train, consistent with the equations in 40 CFR 98.223. Additional changes were made to the monitoring requirements in 40 CFR 98.224 to conform to the changes in the calculation methods in 40 CFR 98.223. We are amending 40 CFR 98.224(a)(1) to clarify when during a nitric acid production campaign facilities must conduct the performance test.

We are also amending the language concerning the Administrator-approved alternative method for determining N2 O emissions in 40 CFR 98.223(a)(2)(ii), 98.224(a)(3), and 98.226(n). The alternative method is for determining N2 O emissions rather than N2 O concentration or an N2 O emission factor. The language has been changed to correct this point.

We are amending the data reporting requirements in 40 CFR 98.226(g) and (m) to be consistent with the calculation methods which are for each nitric acid train, not the facility.

Major changes since proposal are identified in the following list. The rationale for these and any other significant changes can be found in this preamble or the Response to Comments: Technical Corrections, Clarifying and Other Amendments document (see EPA-HQ-OAR-2010-0109).

- Changed the description of the emission factor, EFN2Ot from “lb N2 O generated/ton nitric acid produced, 100 percent acid basis” to “lb N2 O/ton nitric acid produced, 100 percent acid basis.”

- Changed the term “air stream” to “vent stream” at 40 CFR 98.223(g)(1).

- Added Equations E-3b and E-3c of subpart E.

2. Summary of Comments and Responses

This section contains a brief summary of major comments and responses. Two sets of comments were received on this subpart. Responses to additional significant comments received can be found in Response to Comments: Technical Corrections, Clarifying and Other Amendments document (see EPA-HQ-OAR-2010-0109).

Comment: One commenter noted that the regulation for Adipic Acid is similar to the regulation for Nitric Acid and asked that EPA compare the clarifications made to each of these subparts for consistency.

Response: EPA agrees that there are similarities between the two subparts. Although the commenter did not provide specific examples for subpart V, EPA reviewed the commenter's suggested clarifications for subpart E and made the following comparable changes to subpart V:

EPA agrees with the change to the term “air stream.” The term has been changed to “vent stream” in 40 CFR 98.223(g)(1) as this is more consistent with terminology used to identify testing locations at current facilities.

EPA agrees that there could be situations at nitric acid facilities where multiple trains exhaust to a common abatement technology. Language has been added to 98.223(b)(1) to add flexibility for facilities that have a group of trains that exhaust to the same abatement equipment. Further, the equations do not correctly address situations in which a facility has separate N2 O control or abatement technology on the separate train or process lines, back-up controls in parallel on a single train, and these technologies are not operated 100 percent of the time (i.e., operated during maintenance operations on primary controls). We have learned that some facilities could have existing controls (e.g., NSCR) and may apply additional controls during the production process (e.g secondary catalysts in oxidation reactor) in the future.

In these circumstances, the current equations will not provide an accurate calculation of N2 O emissions. To address the three ways in which abatement technology can be employed EPA has revised 40 CRR 98.223 to include calculation methods to accurately account for these possible abatement applications. The current Equation V-3a of subpart V is for one N2 O abatement technology. EPA has added Equation V-3b and V-3c to accommodate situations where multiple N2 O abatement technologies operate in series and or multiple abatement technologies in parallel, respectively. Equation V-3d of subpart V addresses the situation when facilities that do not have N2 O abatement technology.

Comment: According to one commenter, facilities do not have information to determine a point during the campaign which is representative of the average emissions over the entire campaign. The commenter requested that 40 CFR 98.224(a)(1) be modified to ensure that performance tests are conducted during representative operations while enabling operating facilities to document and demonstrate compliance with this objective.

Response: The purpose of this language was to capture emissions data when the process was operating normally. This requirement is to ensure that the emission factor developed through this performance test is an accurate depiction of the quantity of N2 O emitted per quantity of nitric acid produced over the course of an entire year. A campaign was used as a reference due to concerns that N2 O rates from nitric acid plants are somewhat below average at the beginning of a campaign and above average at the end of a campaign. Testing during either of those times could result in an emission factor developed during non-representative conditions. For example, at the end of a campaign, the age of the catalyst may influence emissions. As long as the choice of the timing of the testing is documented and the methods used to determine the timing are documented, this requirement is met. EPA has clarified “average emissions over the entire campaign” to “average emissions rate from nitric acid campaigns” as it is the emissions rate that is obtained during the performance test and a facility may run more than one production campaign over a reporting year. EPA does not agree that the additional changes recommended are needed.

The rule offers flexibility in determining the timing of the performance testing. Facilities may refer to literature and continuous monitoring data from similar facilities in other countries. This literature and data could be used to determine an appropriate test point from a representative or typical nitric acid campaign. The rule provides facilities flexibility on methods to determine this testing point. Further, facilities can also apply to EPA to use alternative methods for determining N2 O emissions.Start Printed Page 66445

L. Subpart Z—Phosphoric Acid Production

1. Summary of Final Amendments and Major Changes Since Proposal

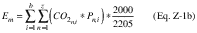

We are renumbering Equation Z-1 as Z-1a of subpart Z and adding a new Equation Z-1b of subpart Z. Equation Z-1b will be used to calculate CO2 emissions when the method used to analyze phosphate rock provides a direct estimate of CO2 emissions instead of just inorganic carbon content.

We have learned from facilities that the “Phosphate Mining States Methods Used and Adopted by the Association of Fertilizer and Phosphate Chemists AFPC Manual 10th Edition—Version 1.9” (AFPC manual) does not currently contain a procedure for obtaining a representative grab sample of rock for testing. A recently updated version of the AFPC manual, Version 1.92, does contain the appropriate sampling procedures. To add flexibility to the rule, we are amending 40 CFR 98.264(a) to allow facilities to use the appropriate industry consensus standards or industry standard practices currently available. We are also amending 40 CFR 98.264(a) to clarify that the grab sample must be collected prior to entering the mill for accurate analysis of inorganic carbon contents.