03-22928. National Emission Standards for Hazardous Air Pollutants: Miscellaneous Coating Manufacturing

-

Start Preamble

Start Printed Page 69164

AGENCY:

Environmental Protection Agency (EPA).

ACTION:

Final rule.

SUMMARY:

This action promulgates national emission standards for hazardous air pollutants (NESHAP) for miscellaneous coating manufacturing facilities. The final rule establishes emission limits and work practice requirements for new and existing miscellaneous coating manufacturing operations, including process vessels, storage tanks, wastewater, transfer operations, equipment leaks, and heat exchange systems, and implements section 112(d) of the Clean Air Act (CAA) by requiring all major sources to meet hazardous air pollutant (HAP) emission standards reflecting application of the maximum achievable control technology (MACT). The HAP emitted from miscellaneous coating manufacturing facilities include toluene, xylene, glycol ethers, methyl ethyl ketone, and methyl isobutyl ketone. Exposure to these substances has been demonstrated to cause adverse health effects such as irritation of the lung, eye, and mucous membranes, effects on the central nervous system, and cancer. We do not have the type of current detailed data on each of the facilities and the people living around the facilities covered by the final rule for this source category that would be necessary to conduct an analysis to determine the actual population exposures to the HAP emitted from these facilities and the potential for resultant health effects. Therefore, we do not know the extent to which the adverse health effects described above occur in the populations surrounding these facilities. However, to the extent the adverse effects do occur, and the final rule reduces emissions, subsequent exposures will be reduced. The final rule will reduce HAP emissions by 4,900 tons per year (tpy) for existing facilities that manufacture miscellaneous coatings.

EFFECTIVE DATE:

December 11, 2003.

ADDRESSES:

Docket ID. No. OAR-2003-0178 and A-96-04 are located at the U.S. EPA, Office of Air & Radiation Docket & Information Center (6102T), 1301 Constitution Avenue, NW., room B108, Washington, DC 20460.

Start Further InfoFOR FURTHER INFORMATION CONTACT:

Mr. Randy McDonald, Organic Chemicals Group, Emission Standards Division (MD-C504-04), U.S. EPA, Research Triangle Park, NC 27711, telephone number (919) 541-5402, electronic mail (e-mail) address mcdonald.randy@epa.gov.

End Further Info End Preamble Start Supplemental InformationSUPPLEMENTARY INFORMATION:

Regulated Entities. Categories and entities potentially regulated by this action include:

Category NAICS* Examples of regulated entities Industry 3255 Manufacturers of coatings, including inks, paints, or adhesives. * North American Industry Classification System. This table is not intended to be exhaustive, but rather provides a guide for readers regarding entities likely to be regulated by this action. To determine whether your facility is regulated by this action, you should examine the applicability criteria in § 63.7985 of the final rule. If you have any questions regarding the applicability of this action to a particular entity, consult the person listed in the preceding FOR FURTHER INFORMATION CONTACT section.

Docket. The EPA has established official electronic public dockets for this action under Docket ID No. OAR-2003-0178 and A-96-04. The official public docket consists of the documents specifically referenced in this action, any public comments received, and other information related to this action. Although a part of the official docket, a public docket does not include Confidential Business Information or other information whose disclosure is restricted by statute. The official public docket is the collection of materials that is available for public viewing at the Air and Radiation Docket in the EPA Docket Center, (EPA/DC) EPA West, Room B102, 1301 Constitution Ave., NW., Washington, DC. The EPA Docket Center Public Reading Room is open from 8:30 a.m. to 4:30 p.m., Monday through Friday, excluding legal holidays. The telephone number for the Reading Room is (202) 566-1744, and the telephone number for the Air and Radiation Docket is (202) 566-1742. A reasonable fee may be charged for copying docket materials.

Electronic Access. You may access this Federal Register document electronically through the EPA Internet under the Federal Register listings at http://www.epa.gov/fedrgstr/. An electronic version of the public docket is available through EPA's electronic public docket and comment system, EPA Dockets. You may use EPA Dockets at http://www.epa.gov/edocket/ to view public comments, access the index listing of the contents of the official public docket, and to access those documents in the public docket that are available electronically. Portions of the docket materials are available electronically through Docket ID No. OAR-2003-0178. Once in the system, select “search,” then key in the appropriate docket identification number. You may still access publicly available docket materials through the Docket ID No. A-96-04.

Worldwide Web (WWW). In addition to being available in the docket, an electronic copy of the final rule will also be available on the WWW through the Technology Transfer Network (TTN). Following signature, a copy of the rule will be placed on the TTN's policy and guidance page for newly proposed or promulgated rules at http://www.epa.gov/ttn/oarpg. The TTN provides information and technology exchange in various areas of air pollution control. If more information regarding the TTN is needed, call the TTN HELP line at (919) 541-5384.

Judicial Review. Under section 307(b)(1) of the CAA, judicial review of the final NESHAP is available only by filing a petition for review in the U.S. Court of Appeals for the District of Columbia Circuit by February 9, 2004. Under section 307(d)(7)(B) of the CAA, only an objection to a rule or procedure raised with reasonable specificity during the period for public comment can be raised during judicial review. Moreover, under CAA section 307(b)(2) of the CAA, the requirements established by the final rule may not be challenged separately in any civil or criminal proceeding brought to enforce these requirements.

Background Information Document. The EPA proposed the NESHAP for miscellaneous coating manufacturing on April 4, 2002 (67 FR 16154), and received 81 comment letters and comments from 8 speakers at a public hearing on the proposal. A background information document (BID) (“National Emission Standards for Hazardous Air Pollutants (NESHAP) for the Miscellaneous Coating Manufacturing Industry, Summary of Public Comments and Responses,”) containing EPA's responses to each public comment is available in Docket ID No. OAR-2003-0178. Start Printed Page 69165

Outline. The information presented in this preamble is organized as follows:

I. Background

A. What is the source of authority for development of NESHAP?

B. What criteria are used in the development of NESHAP?

C. What is the history of the source category?

D. What are the health effects associated with the pollutants emitted from miscellaneous coating manufacturing?

E. How did we develop the final rule?

II. Summary of the Final Rule

A. What are the affected sources and emission points?

B. What are the emission limitations and work practice standards?

C. What are the testing and initial compliance requirements?

D. What are the continuous compliance requirements?

E. What are the notification, recordkeeping, and reporting requirements?

III. Summary of Environmental, Energy, and Economic Impacts

A. What are the air emission reduction impacts?

B. What are the cost impacts?

C. What are the economic impacts?

D. What are the non-air quality health and environmental impacts and energy impacts?

IV. Summary of Responses to Major Comments

A. What changes to applicability did the commenters suggest?

B. How Did We Develop the Standards?

C. Standards for Process Vessels

D. Standards for Storage Tanks

E. Standards for Wastewater

F. Standards for Equipment Leaks

G. Standards for Transfer Operations

H. Pollution Prevention

I. Initial Compliance

J. Ongoing Compliance

K. Recordkeeping and Reporting

L. Startup, Shutdown, and Malfunction

V. Statutory and Executive Order Reviews

A. Executive Order 12866: Regulatory Planning and Review

B. Paperwork Reduction Act

C. Regulatory Flexibility Act

D. Unfunded Mandates Reform Act

E. Executive Order 13132: Federalism

F. Executive Order 13175: Consultation and Coordination with Indian Tribal Governments

G. Executive Order 13045: Protection of Children from Environmental Health and Safety Risks

H. Executive Order 13211: Actions that Significantly Affect Energy Supply, Distribution, or Use

I. National Technology Transfer Advancement Act

J. Congressional Review Act

I. Background

A. What Is the Source of Authority for Development of NESHAP?

Section 112 of the CAA requires us to list categories and subcategories of major sources and some area sources of HAP and to establish NESHAP for the listed source categories and subcategories. Major sources of HAP are those that are located within a contiguous area and under common control and have the potential to emit greater than 9.1 megagrams per year (Mg/yr) (10 tpy) of any one HAP or 22.7 Mg/yr (25 tpy) of any combination of HAP.

B. What Criteria Are Used in the Development of NESHAP?

Section 112 of the CAA requires that we establish NESHAP for the control of HAP from both new and existing major sources. The CAA requires the NESHAP to reflect the maximum degree of reduction in emissions of HAP that is achievable, taking into consideration the cost of achieving the emissions reductions, any non-air quality health and environmental impacts, and energy requirements. This level of control is commonly referred to as the maximum achievable control technology or MACT.

The MACT floor is the minimum control level allowed for NESHAP and is defined under section 112(d)(3) of the CAA. In essence, the MACT floor ensures that all major sources achieve the level of control already achieved by the better-controlled and lower-emitting sources in each source category or subcategory. For new sources, the MACT floor cannot be less stringent than the emission control that is achieved in practice by the best-controlled similar source. The MACT standards for existing sources can be less stringent than standards for new sources, but they cannot be less stringent than the average emission limitation achieved by the best-performing 12 percent of existing sources for which the Administrator has emissions information (or the best-performing five sources for which the Administrator has or could reasonably obtain emissions information for categories or subcategories with fewer than 30 sources).

In developing MACT, we also consider control options that are more stringent than the floor. In considering whether to establish standards more stringent than the floor, we must consider cost, non-air quality health and environmental impacts, and energy requirements.

C. What Is the History of the Source Category?

Section 112 of the CAA requires us to establish rules for categories of emission sources that emit HAP. On July 16, 1992, we published an initial list of 174 source categories to be regulated (57 FR 31576). The listing was our best attempt to identify major sources of HAP by manufacturing category. Following the publication of that listing, we published a schedule for the promulgation of emission standards for each of the 174 listed source categories. At the time the initial list was published, we recognized that we might have to revise the list from time to time as better information became available.

Based on information we collected in 1995, we realized that several of the original source categories on the list had similar process equipment, emission characteristics and applicable control technologies. Additionally, many of these source categories were on the same schedule for promulgation, by November 15, 2000. Therefore, we decided to combine a number of source categories from the original listing into one broad set of emission standards. On November 7, 1996, we published a Federal Register notice combining 21 source categories from the initial list of 174 into the Miscellaneous Organic Chemical Processes source category (61 FR 57602). One of the 21 source categories was the manufacture of paints, coatings, and adhesives.

On November 18, 1999, we published a Federal Register notice describing changes to the source category list (64 FR 63035). At that time, we also described our intent to group the source categories into two new source categories instead of one. The two new source categories are called the miscellaneous organic chemical manufacturing source category and the miscellaneous coating manufacturing source category. We proposed the NESHAP for both source categories on April 4, 2002 (67 FR 16154).

Today's action establishes final standards for miscellaneous coating manufacturing (40 CFR part 63, subpart HHHHH). Final standards for miscellaneous organic chemical manufacturing (40 CFR part 63, subpart FFFF) will be published separately.

D. What Are the Health Effects Associated With the Pollutants Emitted From Miscellaneous Coating Manufacturing?

The CAA was created, in part, “to protect and enhance the quality of the Nation's air resources so as to promote the public health and welfare and the productive capacity of the population” (see section 101(b) of the CAA). These NESHAP will protect public health by reducing emissions of HAP from miscellaneous coating manufacturing facilities.

Miscellaneous coating manufacturing facilities emit an estimated 6,900 Mg/yr (7,600 tpy) of HAP. Approximately 30 Start Printed Page 69166percent of the HAP emitted by miscellaneous coating manufacturing facilities is toluene, 30 percent is xylene, and glycol ethers, methyl ethyl ketone, and methyl isobutyl ketone account for approximately 25 percent. The final rule reduces total HAP emissions from miscellaneous coating manufacturing facilities by 64 percent. As a result of controlling these HAP, the final NESHAP will also reduce emissions of volatile organic compounds (VOC). A summary of the potential health effects caused by exposure to these pollutants is presented in the preamble to the proposed rule (67 FR 16154).

E. How Did We Develop the Final Rule?

We proposed the NESHAP for the Miscellaneous Coating Manufacturing source category on April 4, 2002 (67 FR 16154) and provided an 85-day comment period. We received public comments on the proposed miscellaneous coating manufacturing NESHAP from 81 sources consisting of paint, ink, and adhesives manufacturers, industry trade associations, a federal government agency, an environmental group, and other interested parties. In addition, a public hearing was held, at which 8 of 11 speakers provided testimony related to the proposed miscellaneous coating manufacturing rule. A copy of each of the comment letters is available in Docket ID No. OAR-2003-0178.

The final rule reflects full consideration of all the comments we received on the proposed subpart HHHHH, as well as our reassessment of certain data in the rulemaking record. A detailed response to all comments is included in the BID for the promulgated standards (Docket ID No. OAR-2003-0178).

II. Summary of the Final Rule

A. What Are the Affected Sources and Emission Points?

The affected source for the miscellaneous coating manufacturing source category is the miscellaneous coating manufacturing operations at the facility. These operations include storage tanks, process vessels, equipment components, wastewater treatment and conveyance systems, transfer operations, and ancillary sources such as heat exchange systems.

The final standards for miscellaneous coating manufacturing cover vents from process vessels, storage tanks, wastewater, transfer operations, equipment leaks, and ancillary heat exchange operations. Total baseline HAP emissions for the miscellaneous coating manufacturing source category are estimated to be 6,900 Mg/yr (7,600 tpy).

B. What Are the Emission Limitations and Work Practice Standards?

Process Vessel Vents

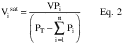

For stationary process vessels with capacities greater than or equal to 0.94 cubic meters (m3) (250 gallons (gal)) at existing sources, the final rule requires an overall reduction, adjusting for capture and control efficiency based on enclosure tests, as applicable, of at least 75 percent by weight for HAP with a vapor pressure greater than or equal to 0.6 kilopascals (kPa) (0.09 pounds per square inch absolute (psia)), and at least a 60 percent reduction by weight for HAP with a vapor pressure less than 0.6 kPa (0.09 psia). The final rule also provides an emissions averaging alternative for stationary process vessels at existing sources that are equipped with a tightly-fitting vented cover. The overall mass reduction in HAP emissions for vessels in the averaging group must be equal to or greater than the reduction that would have resulted if each of the covered vessels were vented to a control device that achieves a 75 percent emissions reduction for HAP with a vapor pressure greater than or equal to 0.6 kPa (0.09 psia) or a 60 percent emissions reduction for HAP with a vapor pressure less than 0.6 kPa (0.09 psia). The final rule requires that portable process vessels at existing sources with capacities greater than or equal to 0.94 m3 (250 gal) be equipped with a cover. Stationary and portable vessels at new sources must be equipped with a tightly-fitting vented cover, and the vented organic HAP emissions must be reduced by at least 95 percent by weight. Alternatively, for stationary process vessels with capacities greater than or equal to 0.94 m3 (250 gal) at existing and new sources and portable process vessels with capacities greater than or equal to 0.94 m3 (250 gal) at new sources, you may install a tightly-fitting vented cover and vent emissions to a condenser operated at specified temperature limits to satisfy the overall control requirement. Another option for meeting the standards for stationary process vessels at existing sources is to use the vessels to produce coatings with less than 5 percent HAP by weight; no additional control of process vessel vents is required when producing such coatings.

We did not specifically request information on process vessels with capacities less than 0.94 m3 (250 gal). Thus, we do not have information indicating that a sufficient number of sources are using control devices or other HAP emission reduction techniques to enable us to set a MACT floor based on such devices or techniques. Therefore, the MACT floor for process vessels with capacities less than 0.94 m3 (250 gal) is no emissions reduction. We examined one regulatory alternative that would require the same 75 percent emissions reduction as for larger process vessels. We concluded that the total impacts of this alternative, including cost, non-air quality health and environmental impacts, and energy requirements, are unreasonable in light of the HAP emission reductions achieved. Thus, we did not develop standards for process vessels with capacities less than 250 gal.

Storage Tanks

The standards for storage tanks at existing sources require either organic HAP emissions reductions of 90 percent by weight or more, or the use of floating roofs, or vapor balancing if the storage tanks have capacities greater than or equal to 75 m3 (20,000 gal) and store material with an organic HAP vapor pressure greater than or equal to 13.1 kPa (1.9 psia). The standards for storage tanks at new sources require either organic HAP emissions reductions of at least 80 percent by weight, the use of floating roofs, or vapor balancing if the storage tanks have capacities greater than or equal to 10,000 gal and store material with an organic HAP vapor pressure greater than or equal to 0.02 psia. The standards for new sources also require either organic HAP emissions reductions of at least 90 percent by weight, the use of floating roofs, or vapor balancing for storage tanks that have capacities equal to or greater than 75 m3 (20,000 gal) but less than 94 m3 (25,000 gal) and store material that has an organic HAP vapor pressure greater than or equal to 10.3 kPa (1.5 psia), and tanks with capacities greater than 94 m3 (25,000 gal) storing material that has an organic HAP vapor pressure greater than or equal to 0.7 kPa (0.1 psia). The final rule does not include standards for storage tanks smaller than 20,000 gal at existing sources or for storage tanks smaller than 10,000 gal at new sources because the MACT floor for these tanks was determined to be no emissions reduction.

Wastewater

For existing sources, the final rule requires that wastewater containing a total partially soluble and soluble HAP load of 750 pounds per year (lb/yr) and a concentration of 4,000 parts per million by weight (ppmw) or greater be treated as hazardous waste or in an Start Printed Page 69167enhanced biological treatment unit. The final rule also allows for offsite treatment provided the affected sources that ship their wastewater to an offsite facility for treatment as a hazardous waste note this fact along with the name of the facility to which the wastewater is shipped in their notification of compliance status report. If the wastewater is shipped offsite for treatment in an enhanced biological treatment unit, the offsite facility must comply with the monitoring, recordkeeping, and reporting requirements in subpart HHHHH. For new sources, the applicability triggers for control are more stringent, affecting all streams that contain partially soluble and soluble HAP at a concentration greater than or equal to 1,600 ppmw.

Transfer Operations

Standards for transfer operations at existing and new sources require 75 percent control of HAP emissions from product loading to tank trucks and railcars if the amount of material transferred contains at least 11.4 million liters per year (l/yr) (3.0 million gal/yr) of HAP, and the material has a HAP partial pressure greater than or equal to 10.3 kPa (1.5 psia). Acceptable control strategies also include routing displaced vapors back to the process, or the use of condensers operated below specified temperature limits.

Equipment Leaks

The final rule requires compliance with leak detection and repair (LDAR) programs for equipment leaks. Existing sources must comply with the sensory-based LDAR provisions of 40 CFR part 63, subpart R, the NESHAP for Gas Distribution Facilities. Alternatively, existing sources may comply with the LDAR program in 40 CFR part 63, subpart TT, or subpart UU (the National Emission Standards for Equipment Leaks—Control Level 1 and Control Level 2, respectively) because these alternatives are equivalent to or more stringent than the sensory-based LDAR program. New sources must comply with either the subpart TT or subpart UU LDAR provisions. For heat exchange systems at existing and new sources, the final rule requires a leak detection program, consistent with the program in 40 CFR 63.104 (the Hazardous Organic NESHAP (HON)).

Cleaning operations are considered part of the miscellaneous coating manufacturing operations at existing and new sources. Therefore, cleaning fluids are considered to be process fluids, and the requirements for process vessels, storage tanks, equipment leaks, and wastewater systems that apply to other process operations also apply to cleaning operations.

C. What Are the Testing and Initial Compliance Requirements?

To verify that the required reductions have been achieved, you must either test or use calculation methodologies, depending on the emission stream characteristics, control device, and the type of process vent. Initial compliance demonstration provisions for stationary process vessels at miscellaneous coating manufacturing sources reference the 40 CFR part 63, subpart SS, closed vent system and performance test provisions and the capture efficiency Method 204 in appendix M to 40 CFR part 51. Control devices handling greater than 9.1 Mg/yr (10 tpy) of HAP must be tested, while engineering assessments are allowed for control devices with lower loads and for condensers. Performance test provisions are based on worst case operating conditions for devices controlling process vents.

The initial compliance demonstration procedures reference 40 CFR part 63, subpart SS, for storage tanks complying using control devices and transfer operations, and 40 CFR part 63, subpart WW, for storage tanks complying using floating roofs.

D. What Are the Continuous Compliance Requirements?

The final rule requires monitoring to determine whether you are in compliance with emission limits on an ongoing basis. This monitoring is done either by continuously measuring HAP emissions reductions or by continuously measuring a site-specific operational parameter, the value of which you would establish during the initial compliance demonstration. These parameters are required to be monitored at 15-minute intervals throughout the operation of the control device. For control devices that do not control more than 1 tpy of HAP emissions, only a daily verification of the operating parameter is required, as is provided in 40 CFR part 63, subpart GGG. To demonstrate compliance with work practice standards, such as the requirement to maintain floating roofs, inspection of equipment serves as the monitoring demonstration.

E. What Are the Notification, Recordkeeping, and Reporting Requirements?

The final rule requires recordkeeping and initial and semiannual reporting. The initial notification is required within 120 days of the effective date of the NESHAP. That report, which is very brief, serves to alert appropriate agencies (State agencies and EPA Regional Offices) of the existence of your affected source and puts them on notice for future compliance actions. The precompliance report details compliance alternatives that require preapproval and is required 6 months prior to the compliance date. The notification of compliance status (NOCS) report, which is due 150 days after the compliance date of the NESHAP, is a comprehensive report that describes the affected source and the strategy being used to comply. The final rule also incorporates a number of provisions in subpart A of 40 CFR part 63 (General Provisions), among them the startup, shutdown and malfunction provisions.

III. Summary of Environmental, Energy, and Economic Impacts

A. What Are the Air Emission Reduction Impacts?

We estimate nationwide baseline HAP emissions from the miscellaneous coating manufacturing sources to be 6,900 Mg/yr (7,600 tpy). We project that the final rule will reduce HAP emissions by about 4,400 Mg/yr (4,900 tpy). Because many of the HAP emitted by miscellaneous coating manufacturing facilities are also VOC, the proposed NESHAP will also reduce VOC.

Combustion of fuels to generate electricity and steam will increase secondary emissions of carbon monoxide (CO), nitrogen oxides (NOX), and sulfur dioxide (SO2) by about 25 Mg/yr (27 tpy). These impacts were estimated assuming electricity is generated in coal-fired power plants and steam is produced in natural gas-fired industrial boilers.

B. What Are the Cost Impacts?

The cost impacts include the capital cost to install control devices and monitoring equipment, and include the annual costs involved in operating control devices and monitoring equipment, implementing work practices, and conducting performance tests. The annual cost impacts also include the cost savings generated by reducing the loss of product or solvent in the form of emissions. The total capital costs for existing sources are estimated to be $57 million, and the total annualized costs for existing sources are estimated to be $16 million. Total capital costs for new sources are estimated to be $1.3 million per new facility and total annualized costs are estimated to be $.25 million per new facility. Three new facilities were estimated in the first 3 years after promulgation of this rule.Start Printed Page 69168

We estimate that in the first 3 years after the effective date of 40 CFR part 63, subpart HHHHH, that the annual cost burden will average $3,500/yr per respondent for recordkeeping and reporting requirements for an estimated 129 sources. Most of these costs are for new and reconstructed sources that must be in compliance upon startup; other costs are for existing sources to prepare initial notifications and plans. In the fourth year after the effective date, existing facilities must begin to monitor and record operating parameters to comply with operating limits and prepare compliance reports. These activities will significantly increase the nationwide annual burden.

We expect that the actual compliance cost impacts of the NESHAP will be less than described above because of the potential to use common control devices, upgrade existing control devices, implement emissions averaging, or comply with the preset temperature limits for condensers. Because the effect of such practices is highly site-specific and data were unavailable to estimate how often the lower cost compliance practices could be utilized, we could not quantify the amount by which actual compliance costs will be reduced.

C. What Are the Economic Impacts?

The economic impact analysis shows that the expected price increase for affected output would be 0.3 percent as a result of the NESHAP for miscellaneous coating manufacturers. The expected change in production of affected output is a reduction of 0.1 percent as a result of the final rule. One plant closure is expected out of the 127 facilities affected by the final rule. It should be noted that the baseline economic conditions of the facility predicted to close affect the closure estimate provided by the economic model, and that the facility predicted to close appears to have low profitability levels currently. Therefore, no adverse impact is expected to occur for those industries that produce output affected by the NESHAP, such as paints, inks, and adhesives.

D. What Are the Non-Air Quality Health and Environmental Impacts and Energy Impacts?

We do not expect wastewater, solid waste, or hazardous waste to be generated from controlling HAP emissions from miscellaneous coating manufacturing facilities. Thus, we expect no non-air quality health impacts from controlling HAP emissions from miscellaneous coating manufacturing facilities. We expect the overall energy demand (i.e., for electricity generation and steam production) to increase by an estimated 32,000 gigajoules per year (30.0 billion British thermal units per year (Btu/yr).

IV. Summary of Responses to Major Comments

A. What Changes to Applicability Did the Commenters Suggest?

Comment: A number of commenters opposed regulation of activities such as mixing additives and other ingredients, thinning, and adjusting tint by facilities that are the end-users of coatings and are subject to any of the surface coating NESHAP; several of the commenters described these activities as “affiliated operations,” and they concurred with the definition and draft preamble language for the Paper and Other Web Coating (POWC) NESHAP that were discussed during POWC stakeholder meetings on May 22 and June 26, 2002.[1] For example, several of the commenters requested specific exemptions for affiliated operations at facilities subject to surface coating rules in subpart GG (National Emission Standards for Aerospace Manufacturing and Rework Facilities), subpart KK of 40 CFR part 63 (NESHAP for the Printing and Publishing Industry), and/or subpart JJJJ of 40 CFR part 63 (NESHAP: Paper and Other Web Coating). Another commenter requested an exemption for the onsite formulation and mixing of specialty, ablative coatings that are applied to space vehicles at a National Aeronautics and Space Administration (NASA) site and are exempt from control under subpart GG of 40 CFR part 63. Two commenters requested specific language in either the preamble or final rule to clarify that operations at facilities subject to subpart DDDD of 40 CFR part 63 (the plywood and composite wood products NESHAP) are not subject to subpart HHHHH of 40 CFR part 63. Another commenter also suggested extending the provision to all equipment associated with a process for which another 40 CFR part 63 standard has been promulgated. One commenter stated that end users, particularly those at facilities subject to subpart MMMM of 40 CFR part 63 (NESHAP: Surface Coating of Miscellaneous Metal Parts and Products), should be exempt because subpart MMMM already addresses emissions associated with the use of diluents at such facilities. Another commenter noted that the exemption in § 63.7985(a)(4) of operations that are part of an affected source under another subpart of 40 CFR part 63 should apply to end-users subject to subparts MMMM, IIII (auto surface), and PPPP (plastic parts and products) because affiliated operations are part of the affected sources under those rules. One commenter requested clarification that the exemption in § 63.7985(a)(4) is not limited only to operations that are required to implement controls under other standards.

Two commenters requested exemptions for affiliated operations at facilities subject to any of the surface coating NESHAP. According to the commenters, the exemption is necessary because we obtained no information on end-users while developing subpart HHHHH, some of the regulated community would not have an opportunity to comment on the proposal because some of the surface coating rules will not be published until after subpart HHHHH is finalized, and we considered emissions from affiliated operations in some surface coating source categories to be insignificant when we were developing the surface coating NESHAP. To exclude end users in general, one commenter recommended more clearly defining “coatings manufacturing” with a definition similar to that for “batch process” in subpart GGG of 40 CFR part 63, using a more narrow listing of Standard Industrial Classification (SIC) and North American Industrial Classification System (NAICS) codes, and adding specific exemptions for temporary activities such as mixing prior to painting a tank or structure at a major source.

Response: The final rule does not apply to activities conducted by end users of coating products in preparation for application. As noted by some of the commenters, we have decided to exempt affiliated operations at POWC facilities from subpart HHHHH. In the preamble to the final POWC surface coating MACT rule (67 FR 72330, December 4, 2002), we define affiliated operations at POWC facilities and indicate that they are part of the POWC source category, but they are not part of the POWC affected source for a variety of reasons. We also examined other surface coating rules, and determined that the exemption for affiliated operations should also be applied to sources that are subject to the printing and publishing rule (subpart KK), the aerospace manufacturing rule (subpart GG), the metal coil coating rule (subpart SSSS of 40 CFR part 63), and the miscellaneous metal parts and products rule (subpart MMMM). These five rules lack requirements for affiliated Start Printed Page 69169operations, but affiliated operations were considered during the development of the rules and controls were determined not to be warranted. We have not extended this exemption to other surface coating rules (or certain other rules) that already include affiliated operations as part of the affected source under the applicable subpart because operations that are part of another affected source are exempt from the final subpart HHHHH according to § 63.7985(a)(4). One commenter's assumption that this exemption is not limited to those operations within another affected source that must implement controls is correct. Preparations for painting equipment or structures at a facility are not part of a manufacturing process and thus are not subject to subpart HHHHH.

Comment: Several commenters recommended clarifying the provision in § 63.7985(c)(3) of the proposed rule that would exempt all equipment associated with a process that has less than 5 percent HAP in process vessels. One commenter noted that this provision will not exempt all water-based coating manufacturing because the actual HAP content in the process vessel varies during the process. To be useful, this commenter stated the determination must be based on the HAP content of the final product. According to another commenter, the exemption should be based on “organic” HAP, and sources should be allowed to determine this percentage based on material safety data sheets (MSDS) or other available information as an alternative to chemical analysis. One commenter suggested that the exemption would be less confusing if it were applied to individual vessels rather than a “coating process” because equipment is generally associated with a specific process vessel and the definition of “process” is too broad. One commenter also stated that if a process vessel is not subject to control because its capacity is less than 250 gallons or the HAP emissions are less than 50 parts per million by volume (ppmv), then it is also reasonable that no other requirements should apply to any of the equipment associated with that process vessel (i.e., the storage tank, equipment leak, and wastewater standards).

To minimize the compliance burden, one commenter requested exemptions for impurities and trace constituents present in quantities less than 0.1 percent by weight for carcinogens and less than 1.0 percent by weight for all other HAP, values which are consistent with the levels that must be provided on MSDS. The commenter stated that this would reduce the burden of determining the HAP content in a vessel for comparison with the 5 percent exemption level and for determining the HAP content in process vessel vents for comparison to the 50 ppmv limit.

Response: Under the proposed rule, whenever the contents of a process vessel contain less than 5 percent HAP by weight, the owner or operator would be exempt from all requirements for the process vessel and related equipment. Under the final rule, this provision has been replaced with a provision that provides for compliance with the stationary process vessel standards at existing sources when the vessel is being used to manufacture a coating that contains less than 5 percent HAP by weight. Our rationale for allowing the mass limit as an alternative standard is based on an estimated equivalent reduction in HAP emissions as compared to complying with the process vessel standards. Although we did not collect specific data on coatings content, we reviewed information that we collected in the development of standards for other coating manufacturing source categories. Based on these data, we concluded that we could achieve equivalent reductions in HAP emissions if coating manufacturers reduce the HAP content of final products to less than 5 percent by weight. In order to achieve equivalent reductions of 75 percent for process vessels, the average HAP content of coatings would have to be greater than 20 percent. Other data collection efforts support the conclusion. For example, the average HAP levels in all the solventborne coatings reported in the metal can and wood building products source categories are 32 and 28 percent, respectively. On a consumption-weighted basis, the HAP content of coatings in the metal can source category is 20 percent. Further, although the HAP content of many water-based coatings is less than 5 percent by weight, we did not include an explicit exemption for waterborne coatings because the HAP content of some waterborne coatings could be relatively high as long as the HAP is soluble in water.

In developing this alternative, we are persuaded by one commenter's suggestion to apply it to all vessels that are associated with the manufacturing of the final product. Although another commenter suggested that identifying all process vessels in a manufacturing process would be confusing, we think that this alternative would actually simplify compliance for most owners and operators. As long as the process vessel meets the definition in the final rule, an owner or operator could comply with the alternative standard when the vessel was processing material that would ultimately contain less than 5 percent HAP by weight as final product.

To further eliminate confusion, we clarified that the alternative applies only to process vessels. Storage tanks are not considered because their control requirements are determined based on the size of the tank and the HAP partial pressure, not whether the tank is used for an individual product. Transfer operations are not considered because their control requirements are determined based on the total annual quantity of coating that is loaded and its weighted average partial pressure. Equipment leaks also are not considered because the need for control is determined by the number of hours a particular component is in organic HAP service within the affected source, not the specific product being produced. Also, we did not exempt wastewater streams from process vessels smaller than 250 gal because we have no evidence that such vessels are cleaned by a different procedure than larger vessels or that the wastewater streams from such cleaning operations are kept separate.

We did not allow in the final rule a de minimis exemption of 0.1 or 1 weight percent HAP for trace constituents. This exemption is not relevant to the 5 weight percent HAP product alternative standard. Further, we do not feel that an additional de minimis or trace constituent exemption for compliance with the remaining standards is necessary.

Comment: One commenter recommended establishing applicability based on the affected source rather than the major source so that small coating manufacturing operations co-located with large surface coating sources are not subject to subpart HHHHH.

Response: We have not made the suggested change because the definition of a “major source” encompasses an entire plant site without being subdivided according to industrial classifications or activities. This definition is contained in section 112(a)(1) of the CAA, which includes “any stationary source or group of stationary sources located within a contiguous area and under common control that emits or has the potential to emit considering controls, in the aggregate, 10 tpy or more of any HAP or 25 tpy or more of any combination of HAP.”

Comment: One commenter requested an exemption for processes with uncontrolled emissions less than 10,000 lb/yr.Start Printed Page 69170

Response: We have not incorporated the requested exemption because it is not supported by the available data.

Comment: One commenter requested an exemption for waterborne coatings.

Response: We have not included an explicit exemption for waterborne coatings because the HAP content of a waterborne coating could be relatively high as long as the HAP is soluble in water. However, a source can reformulate coatings to contain less than 5 percent HAP as a means of meeting the process vessel vent emission limits and work practice standards for existing sources.

Comment: One commenter requested an exemption for low vapor pressure HAP.

Response: We did not provide an exemption for low vapor pressure HAP materials because we could not justify a no emissions reduction MACT floor for these materials based on our information. We did not collect information that could be used to support the concept that process vessels containing only low vapor pressure materials would not be controlled to the same levels as those containing higher vapor pressure materials. Further, we reviewed HAP storage tank throughput at facilities that reported control of process vessels, and noted that lower vapor pressure HAP, such as glycol ethers and ethylene glycol, were also used at these facilities. However, for the final rule, we have written the standard for stationary process vessels at existing sources to require 75 percent reduction only for HAP with a vapor pressure greater than or equal to 0.6 kPa. We made this change based on a revised analysis that showed the total impacts of the regulatory alternative are unreasonable for HAP with vapor pressures less than 0.6 kPa. Thus, these HAP must be controlled to the MACT floor level of 60 percent.

Comment: Three commenters requested clarification of how to determine whether 40 CFR part 63, subpart FFFF, or 40 CFR part 63, subpart HHHHH, applies to their operations. One commenter noted that the proposed definition of “coating manufacturing” is expansive and would unnecessarily subject facilities to both subparts.

Response: If the product being manufactured is a coating, and the manufacturing steps involve blending, mixing, diluting, and related formulation operations, without an intended reaction, then the process is subject to subpart HHHHH. If a reaction as well as various other operations are involved, then the process typically is subject to subpart FFFF. However, if the downstream formulation operations are distinct from the preceding synthesis process(es), (perhaps because the synthesized product is isolated and some of it is sold or transferred offsite), then the formulation operations are subject to subpart HHHHH, and the synthesis operations are subject to subpart FFFF. In the event that equipment used for manufacturing products in processes that are subject to subpart FFFF is also used for coating manufacturing operations that are subject to subpart HHHHH, then the primary use of the equipment determines applicability.

B. How Did We Develop the Standards?

Comment: According to one commenter, the lack of standards for all HAP is unlawful. The commenter cited hydrogen chloride (HCl), hydrogen fluoride, chlorine, potassium compounds, and maleic and phthalic anhydrides as examples of HAP that are not regulated. Another commenter recommended listing the HAP that are subject to the final rule, or cross-referencing Table 2 in subpart F of the HON.

Response: The standards in subpart HHHHH apply to all HAP that are used in coating manufacturing. Of the six compounds cited by the first commenter, only HCl and phthalic anhydride are listed in our database. All process vessels larger than 250 gallons that emit any HAP, including the six cited by the first commenter, must be controlled. We did not list the HAP in the final rule because the rule applies to all HAP listed in the Clean Air Act.

Comment: One commenter stated that the thresholds in the proposed subpart HHHHH unlawfully exempt emission points from control. According to the commenter, all emission points must be controlled.

Response: We disagree that every emission point at a major source must be required to reduce emissions. First, section 112(a) of the CAA defines “stationary source” (through reference to section 111(a)) as: * * * any building, structure, facility, or installation which emits or may emit any air pollutant * * * .” (42 U.S.C. 7412(a)(3) and 7411(a)(3)). The General Provisions for the MACT program define the term “affected source” as * * * the collection of equipment, activities, or both within a single contiguous area and under common control that is included in a section 112(c) source category or subcategory for which a section 112(d) standard or other relevant standard is established pursuant to section 112 * * *.” (40 CFR 63.2). Nothing in the definition of “stationary source” or in the regulatory definition of “affected source” states or implies that each emission point or volume of emissions must be subjected to control requirements in standards promulgated under CAA section 112.

Further, even under the commenter's interpretation of “stationary source,” the Agency would still have discretion in regulating individual emission sources. Section 112(d)(1) of the CAA allows the Administrator to * * * distinguish among classes, types, and sizes of sources within a category or subcategory in establishing such standards * * *.” We interpret this provision for the miscellaneous coating manufacturing NESHAP, as we have for previous rules, as allowing emission limitations to be established for subcategories of sources based on size or volume of materials processed at the affected source. Under the discretion allowed by the CAA for the Agency to consider sizes of sources, we made the determination that certain small-capacity and low-use operations (e.g., smaller storage tanks) can be analyzed separately for purposes of identifying the MACT floor and determining whether beyond-the-floor requirements are reasonable. In addition, our MACT floor determinations for certain categories (e.g., stationary process vessels), which are set according to section 112(d)(3) of the CAA, reflect the performance levels of the best-performing sources for which we had information, including vapor pressure thresholds or cutoffs below which the best-performing sources do not reduce emissions.

In general, our MACT floor determinations have focused on the best-performing sources in each source category, and they consider add-on control technologies as well as other practices that reduce emissions. As part of our information collection effort, we requested information on emission reduction measures. We generally did not receive information indicating that, for the emission points covered by 40 CFR part 63, subpart HHHHH, sources are currently reducing emissions through measures other than control technologies (e.g., by fuel switching or raw materials or process changes) in sufficient numbers to support a MACT floor based on such measures. Accordingly, our standards include a performance level that represents the level achieved by the best control technology, and a threshold or cutoff that represents the lowest emission potential that is controlled by the best 12 percent of sources. Because the miscellaneous coating manufacturing source category is broad in terms of the Start Printed Page 69171numbers and types of processing operations that are covered, one challenge was to develop a format by which all sources could be compared to each other to establish the best-performing sources. The performance level generally is of the format that can be applied to different types of control technology and processes and is generally consistent with existing State and local rules. Thus, different types of control technology and emission levels resulting from existing rules are captured in our MACT floor analysis. The cutoff allows owners and operators that have reduced their emissions below a certain level using one or more methods, including process changes to reduce or eliminate pollution at the source, to comply without additional control. Both performance levels and cutoffs have been set to account for variations in emission stream characteristics so that the standards can be applied consistently across the source category. This approach is consistent with the language of CAA section 112(d)(3) that requires us to set the MACT floor based on the best-performing 12 percent of existing sources.

C. Standards for Process Vessels

Comment: One commenter is not convinced that the existing source MACT floor for portable vessels should be only a cover because some portable vessels have a cover plus add-on control devices, and the actual performance of a covered vessel varies depending on the type of cover and other factors such as the HAP content and vapor pressure of the material being processed. Similarly, the commenter also objected to the existing source MACT floor for stationary process vessels, claiming that it does not reflect the actual performance of the best performers, and that we have not accounted for various factors that affect the performance.

Other commenters indicated that the existing source MACT floor is too stringent, or at the very least the control level should not be increased from 60 percent to 80 percent. For example, one commenter is not convinced that 6 percent, or the average of the best performing 12 percent, are controlled because many of the controls are applied only to vessels with specific characteristics rather than facility-wide. Another commenter questioned the validity of averaging uncontrolled sources with controlled sources in developing the MACT floor, and concluded that the floor should be no control. In response to a solicitation for comment regarding the setting of the floor based on the mean or the median of controlled vessels (i.e., 60 percent versus 80 percent control, respectively), the commenter stated the mean is appropriate for several reasons: (1) There are sufficient data points to use the mean, (2) 60 percent represents a real-world technology, (3) EPA claimed in MACT floor memoranda that the mean is a better measure of the central tendency of the data, (4) EPA indicated during the stakeholder process that the mean would be used as it is representative of the industry and consistent with Congress' intent under the CAA, and (5) EPA guidelines for MACT determinations under CAA section 112(j) state that the MACT floor should be based on the mean unless there is a large discrepancy between the emission reductions achieved by available control options (which the commenter indicated is not the case here because control efficiencies are uniformly distributed between 2 and 99 percent). Numerous other commenters simply stated that the MACT floor has been adequately characterized, and should not be revised

Nearly all of the commenters objected to the apparent requirement for 100 percent capture of emissions for the new and existing source MACT floors for stationary process vessels, and they stated the floor control levels should specify only the efficiency of the control device. They expressed particular concern with a statement in the preamble to the proposed rule that indicated covers must be sealed and gasketed. The commenters noted that 100 percent capture is not feasible (and, therefore, not achieved in practice except possibly if using chemical reaction type vessels and closed solids charging systems) because covers often must include an opening for an agitator shaft, and vessels must be opened periodically to take samples, add material, and perform inspections. They also noted that this requirement contradicts our position in stakeholder meetings and background memoranda, and they concluded that the information collection request (ICR) data do not support a capture component to the floor (i.e., only information about the control efficiency was requested). Even if actual capture efficiencies are allowed, they noted that the proposed overall capture plus control efficiency of 95 percent for process vessels at new sources would be virtually impossible to achieve because it effectively requires nearly 100 percent capture.

Numerous commenters objected to the requirement that emissions from cleaning are subject to control, at least if the vessel does not have an automatic wash system. One commenter noted that most vessels are cleaned by hand, but even vessels that have automatic wash systems must be opened for inspections after cleaning.

Response: We did not adjust the MACT floors for portable or stationary vessels. For portable vessels, the MACT floor is to equip each vessel larger than 250 gal with a cover. Our data show that less than 6 percent of portable vessels are equipped with add-on control devices, but over 90 percent are equipped with covers. We did not receive information regarding any other emission reduction techniques besides the use of covers or add-on control devices for portable vessels in responses to our ICR request for such information. Thus, we do not have information indicating that a sufficient percentage of sources to set a floor are using any emission reduction techniques other than covers, and we cannot support a floor determination based on the use of any other techniques.

Our database includes information for 4,628 stationary process vessels larger than 250 gal. Six percent of all stationary process vessels corresponds to a total of 278 vessels. A total of 368 vessels are equipped with some type of add-on device, or about 8 percent. The average control of the best-performing 12 percent (60 percent reduction) represents a technically feasible level of control and, therefore, we disagree with the assertion that the floor should be no control. The average control efficiency was determined for 368 vessels, including 278 controlled vessels and factoring in no control for the remaining 187 top records.

The commenters also contended that reported efficiencies do not consider capture efficiency. Of the 378 vessels that are controlled, over 278 (6 percent of the stationary process vessels) reported either direct ventilation to control devices, reported closed vent systems to control devices, or reported operating essentially 100 percent capture (routing building exhausts to an incinerator a capture system) and control. Therefore, we concluded that it is appropriate to set the existing source MACT floor for stationary process vessels larger than 250 gal on an overall control efficiency based on the reported efficiencies.

The new source MACT floors for portable and stationary process vessels larger than 250 gal are based on the best-performing source. For both portable and stationary process vessels, the best-performing source covers the vessels and vents emissions through a closed-vent system to a thermal incinerator with an overall control efficiency of 95 Start Printed Page 69172percent. Thus, the MACT floors are based on these conditions.

We recognize that basing MACT floors for stationary and portable vessels on capture and control does not overtly consider fuel, materials, process, or similar changes that could result in lower overall mass emissions. However, based on the information we have, we cannot accurately quantify a level of mass emissions that could result from such emission reduction techniques as a MACT floor and that could be achieved by all coating manufacturers given the variability in processing operations, the scale of processing operations, and products manufactured.

We did not specifically request information for portable or stationary process vessels with capacities less than 250 gal, and we do not have any such information. We set a MACT floor of no emissions reductions because we do not have information indicating that a sufficient percentage of sources are using emission reduction techniques or add-on controls to enable us to set a MACT floor.

The MACT floor for stationary process vessels at existing sources is based on overall control. Thus, the final rule specifies that these process vessels must either be equipped with tightly-fitting vented covers and closed vent systems meeting the requirements of subpart SS of 40 CFR part 63. We have decided to exempt some emissions releases that result from safety and hygiene practices because it is unlikely that these vents would reach the 50 ppmv concentration level defined to be a process vessel vent. The exemption also will relieve owners and operators from the burden of demonstrating that they meet the concentration level. Specifically, the definition of process vessel vent excludes flexible elephant trunk systems that draw ambient air (i.e, systems that are not ducted, piped, or otherwise connected to the unit operations) away from operators that could be exposed to fumes when vessels are opened. As an alternative, capture efficiency must be considered in the overall control efficiency determination if vessels are not equipped with tightly-fitting vented covers and closed vent systems. Opening of covers for addition of materials, sampling, etc., is included as part of the capture efficiency demonstration. For new sources, the final rule requires the use of tightly-fitting vented covers to controls; determining capture is not an option because, as the commenters noted, achieving 95 percent overall control would require nearly 100 percent capture.

Finally, we have not required control of cleaning that is accomplished manually. However, emissions resulting from automatic wash systems are required to be considered and controlled. Similarly, control is required for emissions resulting from flushing of lines or other equipment with solvent at the end of a batch because these are closed operations.

Comment: Most of the commenters stated that the standard for stationary process vessels at existing sources should be set at the MACT floor. According to the commenters, the cost of the regulatory alternative is unreasonable because our analysis overstated the uncontrolled emissions, used unrealistic model plant and emission stream characteristics, and understated the costs.

The commenters disputed our estimate of uncontrolled emissions for a number of reasons. Their primary argument is that using the Emission Inventory Improvement Program (EIIP) equations would give a more accurate estimate of the HAP emissions than the AP-42 VOC emission factor. They noted that EPA has identified the EIIP equations as the preferred method, companies use them as the basis for title V permits, States prefer them for permitting and compliance demonstrations, and EPA specifies the use of similar equations in 40 CFR part 63, subpart GGG. Conversely, they noted that the AP-42 VOC emission factor is inappropriate because, typically, half or less of the VOC is HAP; the factor is meant to estimate emissions from the entire process, not just stationary process vessels; and the industry has shifted to less volatile solvents in recent years. One commenter provided data showing that the EIIP methodology, calibrated with stack testing, results in emissions equal to about 0.2 to 0.6 percent of HAP throughput. Another commenter also noted that our baseline emissions estimate exceeds facility-wide Toxic Release Inventory (TRI) emissions (which also include non-HAP, fugitives, emissions from portable vessels, and emissions from other processes) by factors between 3 and 36. The commenter also does not believe that 5 facilities generate half of the emissions in the source category. For example, the commenter contacted the facility in our database with the highest estimated emissions and determined that only 2 percent of the solvent throughput is attributable to the manufacture of inks and coatings; the remainder is associated with the distribution of paint thinners and paint reducers.

The commenters considered many of the model plant parameters and emission stream characteristics to be unrealistic. Related to their concerns that 100 percent capture is infeasible, they noted that local exhaust ventilation systems usually convey large volumes of air to minimize worker exposure, reduce the risk of fires, and contain dust. As a result of the high air flow rates, they noted that the HAP concentration is much lower than the 40,000 ppmv in our impacts analysis. Based on stack test data, one commenter stated that actual concentrations are less than 1,200 ppmv. Another commenter indicated the concentrations are in the hundreds of ppmv. The commenters noted that for toluene, the surrogate HAP used in our analysis, 40,000 ppmv is within the flammable range, which poses safety concerns and would necessitate the use of expensive fire/explosion prevention equipment and inerting systems. One commenter stated that xylene should be used as the surrogate HAP because it is now four times more prevalent than toluene. The commenters noted that the model included emissions only from filling, but emissions also result from other process steps such as mixing, gas sweep, heat-up, holding, emptying, and cleaning. They also disagreed with the assumption that a control device needs to be sized to handle emissions from only 5 vessels at a time. For example, one commenter indicated that many facilities have dozens of process vessels being filled simultaneously (as much as 50 to 75 percent of all vessels onsite). Another commenter noted that each vessel would have to have its own condenser because a common header poses safety and product quality risks. One commenter objected to the assumption that condensers can be used to control all process vessels because water cooled condensers will not be effective for the low concentration (and high flow) streams in the industry, and condensers are meant to operate for long periods of time under steady-state conditions, not intermittently during filling steps.

According to this commenter, our cost analysis included a number of errors and deficiencies. For example, the analysis did not include the cost to replace existing vessels with chemical reaction type tanks and raw material addition equipment, which would be needed to even approach 100 percent capture. If cleaning emissions must be controlled, the commenter indicated that a cost for automatic wash systems must be included. Fire and safety instrumentation and systems would be needed since the model operates with toluene in the flammable range.

Even if condensers are assumed to be applicable for all process vessels (which Start Printed Page 69173the commenter opposed), the commenter noted the following concerns with the analysis: (1) Solvent recovery is not feasible because the condensed solvent is contaminated with condensed water vapor (and must be disposed of as hazardous waste); (2) the amount of coolant piping and valves per condenser is underestimated; (3) baghouses will be needed upstream of the condenser to remove particulate if solid materials are added to the process vessel; (4) two-stage rather than single stage condensers will be required to operate at the model operating temperature of 32°F; (5) the refrigeration unit needs to be large enough to service 75 percent of the facility's condensers; and (6) costs are needed for foundations and supports, electrical components, instrumentation, insulation, site preparation, and buildings.

The commenter also stated the analysis understates the incremental cost effectiveness relative to the floor because it used uncontrolled emissions rather than baseline emissions; the condenser count is incorrect for more than 30 facilities; the costs for covers were not included for the vessels that do not currently have them; the results reported in $/Mg are actually in $/ton; and the saturation toluene concentration is 37,370 ppmv, not 40,000 ppmv. Based on a sensitivity analysis that incorporates some of these suggested changes and looks at a range of emission stream flows, HAP concentrations, and control devices, the commenter estimated that costs are at least 5 to 20 times higher than our estimate. The commenter noted that these estimates are conservatively low because they do not include costs for chemical reaction tanks, raw material addition equipment, and fire safety equipment; they also do not consider the impact of using a less volatile surrogate HAP on emission reductions. Even without changing the elements in the analysis, the commenter stated that we should consider the average facility cost effectiveness value rather than the nationwide value because a majority of the facilities in the analysis have incremental costs above $3,500/Mg; typically, these facilities are small or produce predominately water-based coatings.

Response: We agree that the EIIP guidance is appropriate for use in estimating emissions from coating manufacturing process sources. We did not use EIIP models because we did not have the level of detail required to conduct emission estimates from the facilities in our database. We considered the 1 to 2 percent solvent throughput values contained in the Chapter 5 AP-42 documentation to be adequate in characterizing the level of emissions for nationwide impacts. And, although one commenter indicated that the EIIP methodology would result in HAP emissions between 0.2 and 0.6 percent of HAP throughput for his facilities, this commenter also calculated a loss of 1.3 percent for one facility due to more conservative assumptions associated with that facility's operations. While our 1 percent factor may be conservative, it was a reasonable value for the impacts analysis. The commenters noted that the AP-42 VOC emission factor is inappropriate because, typically, half or less than half of the VOC is HAP; however, because the factor is based on HAP throughput, only the portion of solvent that is HAP is considered, and therefore, basing the emissions on HAP throughput appropriately limits the estimates to HAP, not VOC. Regarding the comment that our baseline emissions estimate exceeds facility-wide TRI emissions, we note that one commenter indicated that baseline HAP emissions total 6.3 million pounds for all 127 facilities in the database, as compared to our estimate of 13.5 million pounds, roughly a factor of two. Because of the uncertainty associated with estimation methods, and varying operational practices from site to site, these estimates are reasonable.

Regarding assumptions made in our cost analysis of the regulatory alternative for stationary process vessels, we note that the low overall control efficiency (75 percent) enables numerous control scenarios for achieving compliance, including those scenarios where air flows are increased to enable proper capture of emissions from opening in vessels. While we did not cost out this alternative for presentation of impacts, it would likely be a scenario employed by owners and operators. As discussed previously, the two predominant types of control devices are condensers and thermal incinerators. Therefore, to further examine the cost effectiveness of the regulatory alternative, we evaluated the cost effectiveness of applying a capture and control system using thermal incineration. We started with the analyses generated by one commenter, which are based on EPA's COST-AIR control cost spreadsheets for regenerative thermal oxidizers and included the commenter's estimated installation costs for ductwork, auxiliary equipment, vapor collection systems and lids for tanks. The commenter also noted that cost calculations did not include chemical reaction type tanks to approach 100 percent capture, automatic cleaning systems, raw material addition equipment, baghouses or fire control system costs. We also excluded chemical reaction tanks and raw material feed equipment because they would not be needed when high air flow rates and a capture system are used to collect and route emissions from the existing tanks to a thermal incinerator.

The commenter apparently generated an industry-wide cost effectiveness estimate for thermal oxidizers from average flow and concentration value ranges. The commenter did not provide enough information to methodically step through the procedure to arrive at the resulting value of $16,138/Mg. In fact, it was not clear whether the commenter selected ranges of concentrations and flowrates corresponding to 36 stack test data points and then calculated cost effectiveness values from the midpoints of these ranges or whether the commenter calculated the cost effectiveness of 36 stack test data points and developed an arithmetic average. We note that the table supplied by the commenter identifying concentration and flowrate ranges indicates that flowrates and concentrations were considered to be independent of each other and produced a counterintuitive result that flowrate and concentrations would be directly proportional, as opposed to inversely proportional. For example, the low flow rate range midpoint values were listed as 300 cubic feet per minute (cfm) and 50 ppmv, while the high flowrate range midpoints were listed as 7,500 cfm and 1,750 ppmv. We would expect that as flowrates increased, concentrations would decrease, and we concluded that an analysis resulting from the use of these ranges would likely not represent the actual emission stream characteristics. Further, we estimated the cost effectiveness of incinerator controls for these 5 ranges and obtained values ranging from $290,000/Mg for the 300 cfm, 50 ppmv concentration stream to $400/Mg for the stream with 7,500 cfm and 1,750 ppmv, indicating a wide range of cost effectiveness.

We reasoned that a more representative evaluation would be based on a selected model emission stream. This model stream was based on a common value resulting from the histogram presented by the commenter; we selected as model emission stream characteristics a flowrate of 5,000 standard cubic feet per minute (scfm) waste gas and a concentration of 500 ppmv. Our analysis indicated that the cost effectiveness value for this model stream would be $2,200/Mg, assuming only 75 percent reduction of potential HAP emission was achieved. Based on Start Printed Page 69174this result, we concluded that an evaluation of capture and control systems using thermal incineration would result in reasonable costs.

Our original analysis that was the basis for selecting the 75 percent regulatory alternative based on condenser control is still valid and the total impacts, considering the emission reduction achieved as well as cost, non-air quality health and environmental impacts, and energy requirements, are reasonable. Thus, we continue to base the standard for stationary process vessels at existing sources on the regulatory alternative. However, the commenter has pointed out valid concerns regarding our assumptions. Upon review, we agree that we mistakenly overestimated reductions from the regulatory alternative by approximately 15 percent from the uncontrolled levels. Therefore, our estimated total reductions for the regulatory alternative should be on the order of 4,400 Mg/yr, not 5,000 Mg/yr. The revised incremental HAP reduction achieved by the regulatory alternative is about 1,000 Mg/yr, and it reduces costs by an estimated $130/Mg of HAP controlled. The incremental electricity consumption to operate the refrigeration unit for the condensers is about 1.7 million kilowatt hours per year (kWh/yr), and the fuel energy to generate the electricity is about 16 billion Btu/yr. Total CO, NOX, and SO2 emissions from combustion of the additional fuel to generate the electricity is 14 Mg/yr. There would be no wastewater, solid waste, or other non-air quality health or environmental impacts.

Regarding concerns expressed by the commenter on the system design requirements, such as the required size of the refrigeration units, the amount of piping and valves per condenser, and various installation cost elements, we recognize that these costs could be higher, depending on the site specific situation. In general, the costs would increase for the MACT floor condenser system as well as the regulatory alternative condenser system. The basis for selecting the 75 percent regulatory alternative is that the incremental cost between the MACT floor of 60 percent and the regulatory alternative is reasonable when considered in light of the non-air quality health and environmental impacts and energy requirements. In our original analysis based on condensation of toluene, the difference in total annual cost of the two model systems, one rendering an exit gas temperature of 36°F and one rendering an exit gas temperature of 50°F, was about the same, $45,100 for the regulatory alternative, and $43,417 for the MACT floor alternative; our costs did not specifically assume that the condenser system rendering an outlet gas temperature of 36°F would require a precooler; however, our conservative approach to estimating condenser costs based on a minimum surface area would account for the precooler costs, since the calculated surface area of the model condenser system was lower than the minimum size for which costs are available. Given all the cost elements, we note that the significant factor in annualized cost differences between the two alternatives is the recovery credit, which for the regulatory alternative was $37,063 while the recovery credit for the MACT floor alternative was $29,650. When subtracted from the total annual cost, the annualized cost for the regulatory alternative was $8,038, while the annualized cost for the MACT floor alternative was $13,766. Because cost effectiveness is expressed as total annualized cost divided by emissions reductions, recovery credit factors in not only by lowering the total cost of the option, but increases the denominator in the cost effectiveness term. The incremental difference between the two models, and also between the nationwide impacts that were essentially extrapolated from these two models, is negative. Further, the effect of the recovery credit essentially drives this decision, and is valid for our analysis. We assumed that each vessel would be equipped with a condenser and the condensed material could be returned directly to the vessel without further refinement; we do not agree that cross contamination would be a problem under this scenario; further, moisture generated from condensation of humid air does not appear to be a concern currently as indicated by the predominance of air systems and lack of nitrogen blanketing systems on storage tanks.

The commenters suggested that our cost analysis would have yielded different conclusions had we designed the model condensation systems for xylene, rather than toluene. We agree that cost effectiveness of implementing the model condensation systems largely depends on emission potential, which in turn varies according to the volatility of the HAP materials. Therefore, we decided to expand the commenter's issue and determine the HAP materials for which incremental costs for the 75 percent regulatory alternative are reasonable. We conducted an additional analysis on a model set of emission events consisting of identical processing steps, but processing a different HAP. For the analysis we evaluated the following HAP: Toluene, xylene, cumene, phenol, and ethylene glycol. These compounds represent a range of vapor pressures for common HAP in the industry. We found that the incremental cost impacts of going above the MACT floor are unreasonable for HAP with vapor pressures less than that of cumene. Therefore, we revised the regulatory alternative and standard for stationary process vessels at existing sources to include a HAP vapor pressure threshold of 0.6 kPa at 25°C. Emissions of HAP with vapor pressures above the threshold must be controlled to the regulatory alternative level of 75 percent, whereas HAP with lower vapor pressures must be controlled to the MACT floor level of 60 percent. About 1 percent of the total HAP throughput in the industry consists of HAP with vapor pressures below the threshold; thus, we did not revise the incremental impacts for the regulatory alternative.