-

Start Preamble

AGENCY:

Consumer Product Safety Commission.

ACTION:

Final rule.

SUMMARY:

The Danny Keysar Child Product Safety Notification Act, section 104 of the Consumer Product Safety Improvement Act of 2008 (CPSIA), requires the United States Consumer Product Safety Commission (Commission, CPSC, or we) to promulgate consumer product safety standards for durable infant or toddler products. Durable infant and toddler standards must be “substantially the same as” applicable voluntary standards or more stringent than the voluntary standard if the Commission concludes that more stringent requirements would further reduce the risk of injury associated with the product. The Commission is issuing this final rule establishing a safety standard for soft infant and toddler carriers in response to the direction under section 104(b) of the CPSIA.

DATES:

The rule will become effective September 29, 2014 and apply to product manufactured or imported on or after that date. The incorporation by reference of the publication listed in this rule is approved by the Director of the Federal Register as of September 29, 2014.

Start Further InfoFOR FURTHER INFORMATION CONTACT:

Julio A. Alvarado, Office of Compliance and Field Operations, Consumer Product Safety Commission, 4330 East West Highway, Bethesda, MD 20814; telephone: 301-504-7418; email: jalvarado@cpsc.gov.

End Further Info End Preamble Start Supplemental InformationSUPPLEMENTARY INFORMATION:

I. Background and Statutory Authority

The Consumer Product Safety Improvement Act of 2008 (CPSIA, Pub L. 110-314) was enacted on August 14, 2008. Section 104(b) of the CPSIA, part of the Danny Keysar Child Product Safety Notification Act, requires the Commission to: (1) Examine and assess the effectiveness of voluntary consumer product safety standards for durable infant or toddler products, in consultation with representatives of consumer groups, juvenile product manufacturers, and independent child product engineers and experts; and (2) promulgate consumer product safety standards for durable infant and toddler products. Durable infant and toddler standards must be “substantially the same as” applicable voluntary standards or more stringent than the voluntary standard if the Commission concludes that more stringent requirements would further reduce the risk of injury associated with the product.

The term “durable infant or toddler product” is defined in section 104(f)(1) of the CPSIA as “a durable product intended for use, or that may be reasonably expected to be used, by children under the age of 5 years.” Section 104(f)(2)(H) of the CPSIA specifically identifies “infant carriers” as durable infant or toddler products. The Commission has identified at least four types of products that fall within the product category of “infant carriers,” including: Frame backpack carriers, hand-held infant carriers, slings, and soft infant and toddler carriers.

On April 5, 2013, the Commission issued a notice of proposed rulemaking (NPR) for soft infant and toddler carriers. 78 FR 20511. The NPR proposed to adopt as a mandatory standard the current voluntary standard for soft infant and toddler carriers, ASTM F2236-13, “Standard Consumer Safety Specification for Soft Infant and Toddler Carriers” (ASTM F2236-13), without alteration.

The Commission is issuing a final mandatory safety standard for soft infant and toddler carriers. Pursuant to section 104(b)(1)(A) of the CPSIA, the Commission consulted with manufacturers, retailers, trade organizations, laboratories, consumer advocacy groups, consultants, and members of the public to develop this standard, largely through the ASTM process. After publication of the NPR, ASTM approved two revised versions of F2236-13, F2236-13a, on November 1, 2013, and F2236-14, on January 1, 2014. The revisions included in ASTM F2236-14 clarify several issues raised in the comments received on the NPR. Furthermore, the Commission finds that the revisions included in ASTM F2236-14 adequately address the comments received on the NPR. Section V of the preamble below discusses clarifying changes to the standard. The final rule for soft infant and toddler carriers incorporates ASTM F2236-14, by reference, without alteration.

II. Product Description

A. Definition of a Soft Infant and Toddler Carrier

ASTM F2236-14 defines a “soft infant and toddler carrier” as “a product, normally of sewn fabric construction, which is designed to contain a full term infant to a toddler, generally in an upright position, in close proximity to the caregiver.” Additionally, soft infant and toddler carriers are generally designed to carry a child “between 7 and 45 pounds.” ASTM F2236-14 explains that soft infant and toddler carriers are “normally `worn' by the caregiver with a child positioned in the carrier and the weight of the child and carrier suspended from one or both shoulders of the caregiver. These products may be worn on the front, side, or back of the caregiver's body, with the infant either facing towards or away from the caregiver.” Typically, children Start Printed Page 17423are carried in soft infant and toddler carriers on the front of a caregiver; but some products on the market can be configured to carry a child upright on a caregiver's front, back, or hip.

In the United States, soft infant and toddler carriers are available in two broad classes: Structured and nonstructured. Structured soft infant and toddler carriers contain straps and waist belts that connect to the seat area and other carrier components with buckles, straps, and mechanical fasteners. The straps, belts, and seating area of these products are often stiffened with padding and typically have a heavy textile covering. Nonstructured products consist of a flat, textile center with waist straps and very long upper straps (5 to 6 feet) that wrap around the caregiver and are secured by typing the ends of the straps, such as the mei-tai design. ASTM F2236-14 does not distinguish between products based on whether they are structured or nonstructured; therefore, requirements apply equally to all types of soft infant and toddler carriers.

ASTM F2236-14's definition of a “soft infant and toddler carrier” distinguishes soft infant and toddler carriers from other types of infant carriers that are also worn by a caregiver but that are not covered under ASTM F-2236-14, specifically slings (including wraps), and framed backpack carriers. Soft infant and toddler carriers are designed to carry a child in an upright position. Slings are designed to carry a child in a reclined position. However, some slings may also be used to carry a child upright. Thus, the primary distinction between a sling and a soft infant and toddler carrier is that a sling allows for carrying a child in a reclined position. Different hazard patterns arise from carrying a child in a reclined position. Accordingly, slings are not covered by the standard for soft infant and toddler carriers. Like soft infant and toddler carriers, framed backpack carriers are intended to carry a child in an upright position. However, framed backpack carriers are distinguishable from soft infant and toddler carriers because typically, backpack carriers are constructed of sewn fabric over a rigid frame and are intended solely for carrying a child on the caregiver's back.

III. Incident Data

The preamble to the NPR summarized incident data involving soft infant and toddler carriers reported to the Commission from January 1, 1999 to September 10, 2012. 78 FR 20513 (April 5, 2013). CPSC's Directorate for Epidemiology, Division of Hazard Analysis updated this information for the final rule to include soft infant and toddler carrier-related incident data reported to the Commission from September 11, 2012 through July 15, 2013. During the September 11, 2012 to July 15, 2013 time frame, CPSC received 31 new incident reports related to soft infant and toddler carriers. Two of the incidents were fatal, and 29 were nonfatal. Twenty-four of the 29 nonfatal incidents involved injuries. The total count of reported incidents includes emergency department-treated injuries (i.e., injuries reported through the National Electronic Injury Surveillance System (NEISS)).[1] CPSC staff cannot present national emergency department-treated injury estimates for the final rule due to insufficient numbers of NEISS incidents reported during the time period. The number of incidents occurring in 2012 and 2013 is subject to change because the CPSC continues to collect information about such incidents.

A. Fatalities

Both reported fatalities involved suffocation. One suffocation fatality occurred in 2010. The decedent was a 17-day-old infant who was being carried in a soft infant and toddler carrier—facing the mother—while the mother ran errands. The mother reportedly breast fed the victim while walking. The report is unclear about whether the victim was out of the carrier or in the carrier while being fed. The mother found the child nonresponsive in the carrier. The child was placed on life support, which was later removed due to the child's poor prognosis. The second suffocation fatality occurred in 2011. The decedent, a 4-month-old female, was placed prone to sleep on a bed while still in a soft infant carrier.[2]

B. Nonfatalities

Twenty-nine soft infant and toddler carrier-related nonfatal incidents were reported to the CPSC from September 11, 2012 to July 15, 2013. The incident reports demonstrate that an injury occurred in 24 of the 29 incidents. The children's age was unreported or unknown in four of the 29 nonfatal incidents. For the remaining 25 incidents, the ages provided in the reports ranged from 1 month to 18 months, with 64 percent of the total reports involving children 6 months of age or younger.

Among the 24 nonfatal injuries reported, four incidents required hospitalization. Two of the four injuries requiring hospitalization, a skull fracture and a leg fracture, resulted from infants falling out of a soft infant and toddler carrier. The other two injuries that required hospitalization were head injuries to the infant resulting from the caregiver falling. Other injuries included contusions, abrasions, and lacerations, mostly of the head and face. Fourteen of the injuries resulted from falls, either from the caregiver falling while wearing the carrier or from the infant falling out of the carrier.

The remaining five incident reports stated problems with the product but indicated that either no injury had occurred or the report failed to provide information about any injury.

C. Hazard Pattern Identification

CPSC identified hazard patterns among the 31 new incident reports that were similar to the hazard patterns identified among the incidents considered for the NPR. The primary hazard associated with use of a soft infant and toddler carrier continues to be falling, either caregivers falling while wearing the carrier and injuring the child in the carrier, or children falling or facing the risk of falling from the carrier. Hazard patterns are grouped into the following categories in order of frequency of incident reports:

- Caregiver falls (11) [3] ;

- structure, fit, and position issues (7);

- design and finish-related issues [4] (2), (which are also among the 7 in the previous category);

- strap issues (2);

- issues with stitching/seams (1); and

- other issues (10).

Caregiver Falls: Eleven of the 31 incidents (35 percent) reported injuries to the infant in the carrier, when the caregiver slipped or tripped and fell. All of these were emergency department-treated injury (NEISS data) reports.

Structure, fit, and position issues: Seven of the 31 incidents (23 percent) were related to aspects of the leg- and torso-opening design, how the carrier held the infant, and where the soft Start Printed Page 17424infant and toddler carrier was positioned on the caregiver. Examples of scenarios reported include: an infant slipping far down into the carrier and suffering an injury when the caregiver bent over; an infant falling out of the carrier when the caregiver bent forward; and leg circulation-related injuries to the infant. Three injuries were reported in this category, including one hospitalization.

Design-related issues: Two of the reports included in the structure, fit, and position category above stated complaints about how the carrier fit on the caregiver and that the infant got too hot when the carrier was used with the carrier insert. A carrier insert is available with some soft infant and toddler carriers to help support a young infant's head and neck. No one reported injuries in this category.

Strap issues: Two of the 31 incidents (six percent) reported issues with straps, mostly regarding the adjuster breaking or slipping. Both incidents resulted in injuries, including one hospitalization for a skull fracture stemming from a fall when the strap came undone.

Issues with stitching/seams: One incident report (three percent) stated that stitching on a carrier component came undone. However, the infant sustained no injury.

Other issues: Ten incident reports (32 percent) involved non-product-related issues or provided insufficient information for CPSC staff to determine definitively how the product contributed to the incident. The two fatalities are included in this category—one case of an infant suffering respiratory distress while being carried facing inward, and the other case involved an infant put to sleep in a prone position on a bed while still in a soft infant and toddler carrier. In each case, CPSC staff concluded that insufficient information was reported to determine a predominant factor about the product that contributed to the death. Five reports were of incidental injuries sustained by infants while being carried around in a soft infant and toddler carrier. Examples of such incidents include an infant who hit a pole after a bus in which the child was riding suddenly accelerated and an infant who got hurt while being put into a carrier. The remaining three reports involved infants who fell out of the carrier, with no additional information specified.

D. NEISS Data

The soft infant and toddler carrier NPR presented a separate national injury estimate for the 13-year period from January 1999 through December 2011. However, insufficient emergency department-treated injuries associated with soft infant and toddler carriers in 2012 prevent derivation of reportable national estimates.[5] In addition, until NEISS data for 2013 are finalized in spring 2014, partial estimates for 2013 are not available. Hence, injury estimates are not presented separately in this final rule. However, the emergency department-treated injuries are included in the total count of reported incidents presented in section III.C above.

IV. Response to Comments

CPSC received five comments regarding the NPR, including comments from industry, consumer groups, trade associations, and consumers. The comments address eight separate issues related to fastener strength testing requirements, warning label revisions, and the effective date of the final rule. Two commenters generally supported the rule. Comments submitted in response to the NPR are available at: www.regulations.gov, by searching under the docket number of the rulemaking, CPSC-2013-0014. The Commission finds that revisions made to the ASTM voluntary standard, which are incorporated into ASTM F2236-14, approved on January 1, 2014, and published in January 2014, adequately address comments received on the NPR. Accordingly, the Commission will incorporate by reference the most recent version of the voluntary standard, ASTM F2236-14, as the mandatory standard for soft infant and toddler carriers.

We summarize the comments received on the NPR and CPSC's responses below. To make identification of the comments and our responses easier, we placed the word “Comment,” in parentheses, before the comment's description, and the word “Response,” in parentheses, before our response. Additionally, we have numbered each comment to help distinguish among comments. The number assigned to each comment is for organizational purposes only and does not signify the comment's value or importance, or the order in which we received the comment.

A. Fastener Strength

(Comment 1) Two commenters stated that the specified fastener strength test load of 80 pounds in section 7.7.2 of ASTM F2236-13 is too high for soft infant and toddler carriers whose manufacturer-recommended maximum occupant weight for the product is less than 45 pounds. The commenters suggested using a sliding scale for the test load that would adjust the test load by 1 pound for every pound the carrier is rated above or below 45 pounds. For example, for soft infant and toddler carriers designed for a maximum occupant weight of 25 pounds, commenters recommended a fastener test load of 60 pounds (80 pounds minus 20 pounds) instead of an 80-pound force. One commenter stated that for carriers designed for very small occupants, it would be difficult for every load-bearing fastener to be designed to meet the 80-pound test load because such fasteners tend to be large and difficult to handle gently when close to a small infant.

(Response 1) The Commission disagrees with the commenters and declines to modify the final rule based on this comment. ASTM F2236-13 added requirements for fastener strength testing. Each unique load-bearing fastener, except load-bearing fasteners used for a leg opening adjustment, must not break or disengage when subjected to a tensile load of 80-pound force for 5 seconds. The force is applied to the straps or soft goods on either side of the fastener. Leg opening adjustment fasteners are tested to a 45-pound force.

As noted in the NPR, CPSC staff tested fasteners on 14 different soft infant and toddler carriers, including recalled carriers. The manufacturer's recommended maximum occupant weight of the carriers tested ranged from 20 pounds to 45 pounds. CPSC staff found that most of the tested fasteners failed at loads well above the 80-pound force used in the test, while some of the fasteners on recalled products (which were rated at 26-pound maximum occupant weight) failed at 22 pounds to 55 pounds. The Commission agrees with CPSC staff that lowering the test load to a 60-pound force on a carrier rated at 25 pounds does not provide a sufficient safety factor, considering that fasteners from some recalled carriers failed at 55 pounds during testing. Based on the test results, the Commission finds that an 80-pound test load is appropriate, even for carriers with maximum occupant weights below 45 pounds.

All of the buckle and strap fasteners on the 14 carriers that CPSC staff tested were made from plastic. CPSC staff concluded that the characteristics of the plastic used for the fasteners dictated the fastener's ability to withstand the test load. The plastic material on the fasteners that fractured at a lower load was much less ductile, resulting in the fastener fracturing instead of deforming. Accordingly, CPSC staff found that smaller fasteners were as capable as Start Printed Page 17425larger fasteners at meeting the 80-pound test load. Staff concluded that fastener strength was not necessarily proportional to fastener size.

CPSC staff states that the 80-pound test load for the fastener pull test is not directly related to the maximum carrier weight rating. Rather, the 80-pound test load was established based on testing the strength of fasteners on carriers already on the market. Fasteners that meet the required test load are robust enough for expected use during the life of the product. Moreover, CPSC staff believes that it is reasonably foreseeable that some caregivers may use soft infant and toddler carriers with infants whose weight exceeds the manufacturer's recommended occupant weight.

For the reasons discussed, the Commission declines to modify the final rule based on this comment.

B. Fasteners That Support the Head

(Comment 2) Two commenters stated that fasteners that support the head should be exempt from load testing. Non-load-bearing fasteners intended to retain items such as, but not limited to, hoods, bibs, and toy rings are exempt from load testing in ASTM F2236-13. One of the commenters stated: “head support for new born babies is critical,” but to achieve a good, adjustable head support requires fasteners that are slim and easy to use. The commenter designs head support fasteners to carry a certain load; however, the commenter stated that these fasteners are not load bearing and should be exempt from load testing in section 6.4 of the standard.

(Response 2) ASTM balloted and approved two clarifying changes to Note 1 in section 6.4 of the standard, which have been incorporated into ASTM F2236-14. These changes address the commenters' concern. Note 1 exempts non-load-bearing fasteners from the fastener strength tests in section 6.4 and lists examples of non-load-bearing fasteners that are exempt. We note that the list in Note 1 is not exhaustive, but merely illustrative, and that other features attached to a soft infant and toddler carrier by a non-load-bearing fastener are also exempt from the fastener strength tests in section 6.4.

ASTM F2236-13, the proposed standard for adoption in the NPR, stated that fasteners intended to retain items such as “hoods, bibs and toy rings” were exempt from testing. The ASTM subcommittee for soft infant and toddler carriers was aware of a feature called a “sleeping hood” that is attached to a soft infant and toddler carrier by non-load bearing fasteners. The “sleeping hood” feature was intended to be captured in ASTM F2236-13 Note 1 with the phrase “hoods.” To clarify that non-load-bearing fasteners used to retain “sleeping hoods” are exempt from testing, ASTM changed the word “hoods” in Note 1 to “sleeping hoods.” This revision was approved and published in ASTM F2236-13a.

Subsequently, based on a manufacturer's concern that Note 1 was still unclear about whether head adjustment fasteners that were non-load bearing had to be tested, ASTM balloted and approved another modification to Note 1. The second modification was incorporated into ASTM F2236-14 and added “head adjustment fasteners” to the list of examples of fasteners exempt from testing in Note 1. The Commission agrees with the clarification and believes that these revisions to the voluntary standard address the commenters' concern.

To the extent that commenters are suggesting that any potential load-bearing fastener that supports the head should be excluded from the fastener strength test in section 6.4 of the standard, the Commission disagrees. CPSC found that on the 14 carriers tested, the uppermost fastener generally supports the infant's upper torso and shoulders, as well as the head, and therefore, the fastener is critical to securing the infant in the carrier. Load-bearing fasteners that support the head, upper torso, and shoulders are not exempt from fastener-load testing requirements. The commenter apparently does not intend to exempt this type of fastener from testing.

C. Fastener Strap Slip During Load Testing

(Comment 3) One commenter stated that the strap slippage requirement as articulated in the standard (ASTM F2236-13, paragraphs 6.4.1 and 6.4.2) can result in a technical failure of an otherwise safe product. The commenter found that during product testing, certain straps can slip more than 1 inch but in a direction that makes the straps become tighter, not looser. The commenter asserted that this does not compromise safety. The commenter suggested that the language in paragraph 6.4.1 should be changed from “. . . adjustable elements in straps shall not slip more than 1 in. (2.5 cm) when tested . . .” to “. . . adjustable elements in straps shall not loosen more than 1 in. (2.5 cm) when tested . . . .”

(Response 3) The strap slippage requirement in section 6.4.1 of ASTM F2236-13, the standard referenced in the NPR, prevents the fastener straps from slipping an appreciable amount through the buckles during fastener strength testing. Significant slippage can result in a minimal load being held by the fastener/strap and could result in the strap pulling out of the fastener or loosening to the point that the infant could fall out of the carrier. The commenter seeks to clarify that straps that tighten during the test do not constitute a test failure.

The Commission agrees that straps that tighten during testing should not fail the strap retention requirement in the standard. However, based on the CPSC staff's assessment, the Commission finds that use of the word “slip” in the standard is more accurate than “loosen.” The amount of strap “slip” through a fastener can be measured; whereas, CPSC staff is uncertain how to measure strap “loosening.” Additionally, the requirement for support/shoulder strap slippage during the dynamic and static load testing in paragraph 6.2 uses the same wording, which states: “adjustable sections of the support/shoulder straps shall not slip more than 1 in. (25 mm) per strap from their original adjusted position . . .” Therefore, the Commission will not replace the word “slip” with “loosen” in the final rule, as suggested by the commenter.

After publication of the NPR, ASTM balloted and approved a modification to the voluntary standard that addresses the commenter's concern about straps that tighten during testing. ASTM F2236-14 incorporates a revision to sections 6.2.2, 6.4.1, and 6.4.2 of the voluntary standard to state: “straps shall not slip, in a manner that loosens the strap, by more than 1 inch.” This modification was included in the voluntary standard, beginning with revision ASTM F2236-13a.

The Commission finds that the revisions now incorporated into sections 6.2.2, 6.4.1, and 6.4.2 of ASTM F2236-14 addresses the commenter's concern and clarifies when fasteners pass the fastener strength test requirement without substantively altering the test method.

D. Warning Text Format

(Comment 4) One commenter noted that in ASTM F2236-13, the text height requirement for the warnings provided with product instructions specified in section 9.2.2 needs to be modified to match the text height requirement for warning labels in section 8.3.1. The commenter stated that if this modification is not made, section 9.2.2 would require every letter of warning text to be at least 0.1″ high, instead of only the upper case letters, as is the case in section 8.3.1.

(Response 4) The Commission agrees that the text height requirement for Start Printed Page 17426warnings should be consistent throughout the standard. To address the commenter's concern, ASTM balloted and approved the following modified text in section 9.2.2, as follows (additions are shown by italics):

Section 9.2.2 of the voluntary standard incorporates this revision, beginning with ASTM F2236-13a. The Commission believes that the revised language addresses the commenter's concern.

E. Suffocation Warning

(Comment 5) One commenter stated that the required warning statement should read: “Infants, especially those under four months, can suffocate in this product if face is pressed tight against your body,” rather than the warning statement in the proposed rule, as provided in the ASTM standard: “Suffocation Hazard—Infants under 4 months can suffocate in this product if face is pressed tight against your body.” The commenter said that this warning language does not adequately warn the user of the risk of suffocation for infants over four months and that the suggested warning statement will alert parents and other caregivers to a risk to older babies as well.

(Response 5) The Commission disagrees that the proposed suffocation warning, as provided in the ASTM voluntary standard, does not adequately warn users of the risk of suffocation. The primary mechanism for suffocation in a soft infant and toddler carrier is the infant's face being pressed tightly against a caretaker's body, obstructing the nose and mouth and keeping the infant's head from moving. Infants younger than 4 months old are mostly at risk because they do not have the head control or the muscle strength to move their head away if their airway becomes obstructed. By 4 months of age, infants have increased neck strength and can hold their heads up and explore their surroundings while the caretaker is walking. Infants who are 4 months old can be carried in the outward-facing position in soft infant and toddler carriers that allow this carry position. At around age 6 months, infants begin to sit upright unassisted. Caretakers can carry infants of this age in a soft infant and toddler carrier on the hip or on the caregiver's back, depending on the caretaker's level of comfort. As children reach toddlerhood, caregivers can carry children in this age group in a carrier on the hip or back depending on the carrier type. Given that infants from age 4 months and older have developed head control and muscular strength and can be placed in outward facing, hip, and back carry positions, their face is less likely to become pressed tightly into a caretaker's body. Therefore, the risk of suffocation for these children is low. The Commission has not received data indicating that a risk of suffocation exists for children 4 months and older.

Identifying explicitly children who are most at risk does not suggest that others are not at risk. However, guidelines for warning labels recommend focusing on the most likely and most serious risks (Laughery and Hammond, 1999; Wogalter, 2006). Warnings about low-probability events (i.e., older infants suffocating in soft infant carriers) may reduce the believability or arousal strength of warnings that caution of more likely risks (i.e., infants under 4 months suffocating in soft infant carriers). The Commission finds that the current ASTM warning label about the suffocation hazard is sufficient without modification.

F. Stability Warning

(Comment 6) One commenter stated: “we are concerned that raising the upper weight limits, for the purpose of ensuring that all soft infant and toddler carriers on the market are covered by the rule, brings in carriers that might have a greater risk of instability and falls due to the extra weight load relative to the weight and strength of the caregiver. We would urge the Commission to include an adequate alert to this risk in the required warnings and instructions.”

(Response 6) During the rulemaking, CPSC staff identified soft infant and toddler carriers on the market that have a manufacturer-recommended upper weight limit of 45 pounds. The Commission believes that expanding the scope of the standard to increase the upper weight limit from 25 pounds to 45 pounds is necessary for the standard to cover all products on the market. However, for the Commission to include a warning statement about the greater risk of instability and falls involving products with higher weight limits, data must be available to demonstrate that carrying heavier children in soft infant and toddler carriers presents a greater risk of instability and falls. At this time, the available data do not support this position. Furthermore, the commenter did not provide data demonstrating that products with higher weight limits present a greater risk of instability and falls than carriers with a lower weight limit. Therefore, at this time, the Commission declines to modify the warning label as suggested by the commenter.

G. Product Marking

(Comment 7) One commenter recommended that the CPSC require that products manufactured after the effective date of the final rule be marked as compliant, so that consumers can identify clearly products that meet the new mandatory standard for soft infant and toddler carriers.

(Response 7) The Commission finds that sufficient incentive exists for compliant producers to label their products as compliant with the final standard for soft infant and toddler carriers. A final rule implementing testing, certification, and labeling of children's products in section 14 of the CPSA, as amended by the CPSIA, Testing and Labeling Pertaining to Product Certification, 16 CFR part 1107 (the 1107 rule), became effective on February 13, 2013. Under the 1107 rule, a manufacturer or importer may label a certified compliant product as “Meets CPSC Safety Requirements.” Because producers are already allowed to label compliant products as such under the 1107 rule, adding this option to the soft infant and toddler carrier standard would be redundant. The Commission declines to change to the final rule based on this comment.

H. Effective Date

(Comment 8) Two commenters address the 6-month effective date proposed in the NPR. One commenter, Start Printed Page 17427representing several advocacy groups, expressed support for the 6-month effective date. Another commenter, a soft infant and toddler carrier manufacturer, recommended a 12-month effective date, stating that the manufacturing process can take up to 6 months, and the product may be stocked in a warehouse for additional months, depending on sales.

(Response 8) The final standard will not be applied retroactively to products manufactured prior to the effective date of the final rule. Thus, any products warehoused before the effective date will not be affected by the standard. Manufacturers should be able to comply with the mandatory standard within 6 months of the final rule's publication. Manufacturers whose products do not comply with the standard will require some product modification. However, product modification is expected to involve minor changes, such as adding or changing straps or fasteners. Moreover, ASTM F2236-13 was adopted by ASTM in March 2013, and became effective in September 2013. Although the Commission is adopting ASTM F2236-14 as the mandatory standard, no substantive changes have been made to the voluntary standard since ASTM F2236-13. Manufacturers that comply with ASTM F2236-13 have already made, or have begun to make, the necessary modifications. The Commission declines to change the effective date of the final rule based on this comment.

V. Summary of ASTM F2236-14

The Commission is issuing this final rule for soft infant and toddler carriers that incorporates by reference the most recent voluntary standard for soft infant and toddler carriers, ASTM F2236-14. Together with the changes made in ASTM F2236-12, ASTM F2236-13, and ASTM F2236-13a, ASTM F2236-14 reflects the most significant revisions to the standard to date. Revisions to the voluntary standard include modified and new requirements developed by CPSC staff, working with stakeholders on the ASTM subcommittee task group, to address the hazards associated with soft infant and toddler carriers. After the comment period for the NPR closed, the ASTM F15.21 Soft Infant and Toddler Carrier subcommittee held a teleconference on August 12, 2013, to discuss comments submitted on the NPR. The subcommittee discussed the basis for each comment and reached a consensus on revisions to be submitted for ballot. The subcommittee chair balloted the proposed revisions to ASTM F2236-13 for concurrent ASTM Main Committee F15 and Subcommittee F15.21 consideration on August 23, 2013, with a 1- month comment period. The August 23, 2013 ballot contained three revisions to the voluntary soft infant and toddler carrier standard:

- Revisions to sections 6.2.2, 6.4.1, and 6.4.2 to clarify that during the dynamic load, static load, and fastener strength tests, straps shall not slip, in a manner that loosens the strap, more than 1 inch.

- A revision to Note 1 in section 6.4 to clarify that “sleeping hoods” are an example of non-load-bearing fasteners that are exempt from fastener strength testing.

- A revision to section 9.2.2 to clarify that the text height requirements for the warnings included with instructions in section 9.2.2 are the same as the text height requirements for warnings required in section 8.3.1 of the voluntary standard.

ASTM did not receive any negative votes on the balloted revisions to ASTM F2236-13. ASTM approved the balloted revisions on November 1, 2013, and subsequently published ASTM F2236-13a in November 2013.

On September 26, 2013, the ASTM F15.21 Soft Infant and Toddler Carrier subcommittee met to discuss results of the items balloted on August 23, 2013. One manufacturer wanted the voluntary standard to further clarify that fasteners used for adjusting the head portion of the carrier were exempt from fastener strength testing because such fasteners are not load bearing. As a result, the subcommittee chair developed a draft ballot item that proposed to add “head adjustment fasteners” to the list of examples of fasteners that are exempt from load testing listed in Note 1 of section 6.4. The subcommittee chair balloted the proposed revision to ASTM F2236-13a for concurrent ASTM Main Committee F15 and Subcommittee F15.21 consideration on November 6, 2013, with a 1-month comment period. ASTM did not receive any negative votes on the balloted revision, and approved the revised standard, ASTM F2236-14, on January 1, 2014. ASTM published ASTM F2236-14 in January 2014.

We summarize the provisions of ASTM F2236-14 below. Each revision to ASTM F2236-13 discussed above is described below in more detail in the relevant section of the standard where the change appears. ASTM F2236-14 includes the following key provisions: scope, terminology, general requirements, performance requirements, test methods, marking and labeling, and instructional literature.

Scope. The scope of the voluntary standard was broadened in December 2012 to include soft infant and toddler carriers with an upper weight limit of up to 45 pounds. Previously, it was unclear whether carriers with upper weight limits over 25 pounds fell within the standard. Expanding the scope of the standard clarifies that all soft infant and toddler carrier products currently on the market fall within the standard. The name of the standard was changed in 2012 to include the word “toddler,” to clarify that toddlers can also be carried in these products. The scope of the standard also distinguishes soft infant and toddler carriers from other wearable infant carrier products. The scope provides that soft infant and toddler carriers are “normally of sewn fabric construction,” hold the child “generally in an upright position,” and “may be worn on the front, side, or back of the caregiver's body.” Finally, the scope of the standard states that the standard does not apply to infant slings.

Terminology. Section 3.1 of the standard includes 14 definitions to help explain general requirements and performance requirements. Section 3.1.7 of the standard explains that a “leg opening” is the “opening in the soft carrier through which the occupant's legs extend when the product is used in the manufacturer's recommended use position.” Sections 3.1.4 and 3.1.13 of ASTM F2236-14, respectively, explain that a “dynamic load” is the “application of impulsive force through free fall of a weight,” and that a “static load” is a “vertically downward force applied by a calibrated force gage or by dead weights.” Beginning in 2012, the standard included a new definition for “carrying position” to clarify methods for dynamic and static load testing in section 7 of the standard. Finally, in 2013, the standard was updated to include a new definition for “fastener” to aid in a new test for fastener strength and strap retention.

General Requirements. ASTM F2236-14 includes general requirements that the products must meet, as well as specified test methods to ensure compliance with the general requirements, which include:

- Restrictions on sharp points or edges, as defined by 16 CFR §§ 1500.48 and .49;

- restrictions on small parts, as defined by 16 CFR part 1501;

- restrictions on lead in paint, as set forth in 16 CFR part 1303;

- requirements for locking and latching devices;

- requirements for permanent warning labels;Start Printed Page 17428

- restrictions on flammability, as set forth in 16 CFR part 1610;

- requirements for toy accessories, as set forth in ASTM F 963.

The flammability requirement in section 5.7 of the standard was changed, beginning with ASTM F2236-13, from a flammable solids requirement (16 CFR 1500.3(c)(6)(vi)), to meet the more stringent flammability requirement for wearing apparel (16 CFR part 1610). Adopting the wearing apparel flammability requirement in the soft infant and toddler standard makes it consistent with other wearable infant carriers made of sewn fabric, such as slings, to prevent a foreseeable fire hazard in all wearable infant carriers.

Performance Requirements and Test Methods. ASTM F2236-14 provides performance requirements and test methods that are designed to protect against falls from the carrier due to large leg openings, breaking fasteners or seams, and straps that slip, including:

Leg Openings—Tested leg openings must not permit passage of a test sphere weighing 5 pounds that is 14.75 inches in circumference.

Dynamic and Static Load—Beginning with the 2012 version of ASTM F2236, the dynamic load test was strengthened from requiring a 25-pound shot bag to be dropped, free fall, from 1 inch above the seat area onto the carrier seat 1,000 times, to requiring testing with a 25-pound shot bag, or a shot bag equal to the manufacturer's maximum occupant weight limit, whichever is heavier. Additionally, the static load test was revised—from requiring a 75-pound weight for testing—to requiring a 75-pound weight, or a weight equal to three times the manufacturer's recommended maximum occupant weight, whichever is greater, to be placed in the seat area of the carrier for 1 minute. Such revisions to the dynamic and static load tests strengthen the test requirements, by requiring that products with a maximum recommended weight of 45 pounds be tested to a 135-pound weight instead of 75 pounds, which represents an 80 percent increase in the severity of the requirement.

ASTM F2236-14 requires that testing conducted with the new required loads must not result in a “hazardous condition,” as defined in the general requirements, or result in a structural failure, such as fasteners breaking or disengaging, or seams separating when tested in accordance with the dynamic and static load testing methods. Additionally, the standard provides that dynamic and static load testing must not result in adjustable sections of support/shoulder straps slipping more than 1 inch per strap from their original adjusted position after testing.

Section 6.2.2 of the standard on Support/Shoulder Strap Slippage was modified beginning with ASTM F2236-13a. The modification clarifies what constitutes passing or failing the strap slippage test. Section 6.2.2 was amended to state: “Adjustable sections of support/shoulder straps shall not slip , in a manner that loosens the strap, more than 1 in. (25 mm) per strap from their original adjusted position after dynamic and static load testing is performed in accordance with 7.2.1 and 7.2.2, respectively.” The amendment allows straps to tighten during testing but not loosen more than 1 inch, which is the intent of the testing.

Fastener Strength and Strap Retention— ASTM F2236-14 includes a new component-level performance requirement that was added to the standard in 2013 to evaluate the strength of fasteners and strap retention to help prevent falls from a carrier. Previously, soft infant and toddler carriers were recalled due to an occupant fall hazard caused by broken fasteners that passed the static and dynamic performance requirements in the then existing standard, ASTM F2236-10. Accordingly, the performance requirement in section 6.4 of ASTM F2236-14 states that load-bearing fasteners at the shoulder and waist of soft infant and toddler carriers, such as buckles, loops, and snaps, may not break or disengage; nor may their straps slip more than 1 inch when subjected to an 80-pound pull force. Adjustable leg opening fasteners must also be tested but are subjected to lower loads, a 45-pound pull force, because these fasteners do not carry the same load as fasteners at the shoulders and waist. ASTM F2236-14 requires that when tested, fasteners must not break or disengage, and adjustable elements must not slip more than 1 inch.

Similar to the strap slip requirement in the static and dynamic load testing section of the standard, ASTM also clarified the strap slip section of the fastener strength test section in ASTM F2236-13a. Sections 6.4.1 and 6.4.2 were amended to state: “Each unique fastener, except for leg opening adjustment fasteners as tested per 6.4.2, shall not break or disengage, and adjustable elements in straps shall not slip , in a manner that loosens the strap, more than 1 in. (2.5 cm) . . . .” This amendment allows straps to tighten during testing but not to loosen more than 1 inch, which is the intent of the testing.

Additionally, Note 1 to section 6.4 of the standard provides that the fastener strength and strap retention testing apply only to load-bearing fasteners. ASTM F2236-13 stated: “Fasteners intended to retain items such as, but not limited to, hoods, bibs and toy rings, are exempt from these requirements.” ASTM approved two changes to the language in Note 1 to clarify that several non-load-bearing features, “sleeping hoods” and “head adjustment fasteners,” are included in the list of examples exempted from fastener strength testing when such features are non-load-bearing. Note 1 in section 6.4 of ASTM F2236-14 now provides that: “Fasteners intended to retain items such as, but not limited to, sleeping hoods, head adjustment fasteners, bibs and toy rings, are exempt from these requirements.”

Unbounded Leg Opening—The voluntary standard was updated in 2013 to clarify the unbounded leg opening test procedure to improve test repeatability. ASTM F2236-14 requires that an unbounded leg opening must not allow complete passage of a truncated test cone that is 4.7 inches long, with a major diameter of 4.7 inches and a minor diameter of 3 inches. The standard requires a test cone to be pulled through the leg opening with a 5-pound force for 1 minute.

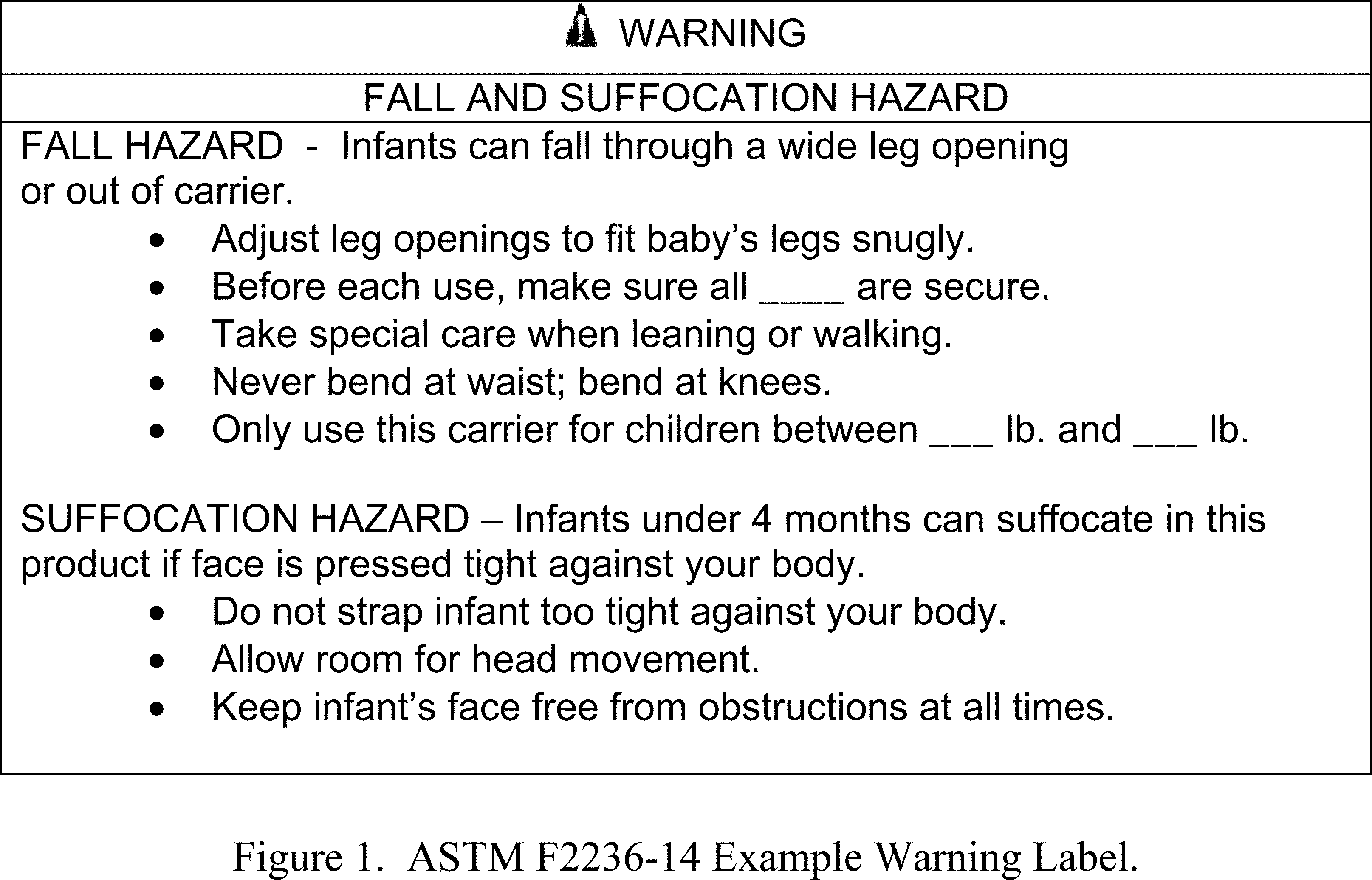

Marking, Labeling, and Instructional Literature. ASTM F2236-14 requires that each product and its retail package be marked or labeled with certain information and warnings. The warning label requirement was updated in 2013 to address fall and suffocation hazards. ASTM F2236-14 requires that the warning label provide a fall hazard statement addressing that infants can fall through wide leg openings or out of the carrier. The standard requires the following fall-related precautionary statements be addressed on the warning label: Adjust leg openings to fit baby's legs snugly; before each use, make sure all [fasteners/knots] are secure; take special care when leaning or walking; never bend at waist, bend at knees; only use this carrier for children between _ lbs. and _ lbs. Additionally, ASTM F2236-14 requires that a suffocation hazard statement must address the fact that infants under 4 months old can suffocate in the carrier if the child's face is pressed tightly against the caregiver's body. The standard requires that the warning label must also address the following suffocation-related precautionary statements: Do not strap infant too tightly against your body; allow room for head movement; keep infant's face free from obstructions at all times. Products must also contain an informational statement that a child must face toward the caregiver until he Start Printed Page 17429or she can hold his or her head upright. All products are required to come with instructional literature on assembly, use, maintenance, cleaning, and required warnings.

ASTM F2236-14 includes an example warning label that identifies more clearly the hazards, the consequences of ignoring the warning, and how to avoid the hazards. The label format was designed to communicate more effectively these warnings to the caregiver (Fig. 1). Manufacturers may alter the rectangular shape of the label to fit on shoulder straps, if the manufacturer chooses not to place label in the occupant space. However, the standard requires that the label be placed in a prominent and conspicuous location, where the caregiver will see the label when placing the soft infant and toddler carrier on their body.

VI. Effective Date

The Administrative Procedure Act (APA) generally requires that the effective date of the rule be at least 30 days after publication of the final rule. 5 U.S.C. 553(d). The NPR proposed that the final rule would become effective 6 months after publication of a final rule in the Federal Register. Although we received one comment requesting a 12-month effective date (comment 8 in section IV.H), the Commission finds that a 6-month effective date is sufficient time to allow manufacturers to come into compliance. Manufacturers whose products are not compliant with the standard will require some product modification; however, any necessary product modification is expected to involve minor changes, such as adding or changing straps or fasteners. Moreover, ASTM F2236-13 was adopted by ASTM in March 2013, and became effective in September 2013. Start Printed Page 17430Although the Commission is adopting ASTM F2236-14, this version of the voluntary standard is substantially the same as ASTM F2236-13. Manufacturers that are compliant with ASTM F2236-13 have already made or have begun to make the necessary modifications.

VII. Regulatory Flexibility Act

A. Introduction

The Regulatory Flexibility Act (RFA) requires that final rules be reviewed for their potential economic impact on small entities, including small businesses. Section 604 of the RFA requires that CPSC prepare a final regulatory flexibility analysis (FRFA) when the Commission promulgates a final rule. The FRFA must describe the impact of the rule on small entities and identify any alternatives that may reduce the impact. Specifically, the FRFA must contain:

- A succinct statement of the objectives of, and legal basis for, the rule;

- a summary of the significant issues raised by public comments in response to the initial regulatory flexibility analysis, a summary of the assessment of the agency of such issues, and a statement of any changes made in the proposed rule as a result of such comments;

- a description of, and, where feasible, an estimate of, the number of small entities to which the rule will apply;

- a description of the projected reporting, recordkeeping, and other compliance requirements of the rule, including an estimate of the classes of small entities subject to the requirements and the type of professional skills necessary for the preparation of reports or records; and

- a description of the steps the agency has taken to reduce the significant economic impact on small entities, consistent with the stated objectives of applicable statutes, including a statement of the factual, policy, and legal reasons for selecting the alternative adopted in the rule, and why each one of the other significant alternatives to the rule considered by the agency, which affect the impact on small entities, was rejected.

B. Market for Soft Infant and Toddler Carriers

Soft infant and toddler carriers are generally produced and/or marketed by juvenile product manufacturers and distributors. Several of these firms primarily produce soft infant and toddler carriers, as well as substitute products, such as slings. CPSC Economic Analysis (EC) staff believes that there are at least 54 suppliers of soft infant and toddler carriers to the U.S. market.[6] Thirty-nine domestic firms supply soft infant and toddler carriers to the U.S. market: 23 are domestic manufacturers; eight are domestic importers; and eight firms have unknown supply sources. In addition, 12 foreign firms supply soft infant and toddler carriers to the U.S. market. CPSC has insufficient information available to categorize the remaining three firms.[7]

According to a 2005 survey conducted by the American Baby Group (2006 Baby Products Tracking Study), 51 percent of new mothers own soft infant and toddler carriers.[8] Approximately 30 percent of soft infant and toddler carriers are handed down or purchased secondhand.[9] Thus, about 70 percent of soft infant and toddler carriers are acquired new. This estimate suggests that approximately 1.5 million soft infant and toddler carriers are sold to households annually (0.51 x 0.70 x 4.1 million births per year).[10]

Many soft infant and toddler carriers have expanded their maximum weight limits in recent years to accommodate older children. However, from the lack of incident data involving children older than 2 years, CPSC staff believes that most caregivers would not be comfortable carrying older, heavier children in soft infant and toddler carriers. Based on the incident data, it appears that soft infant and toddler carriers are used during a child's first year, with some caregivers continuing to use these products into the second year. While we do not know the proportion of caregivers who continue to use these products into the second year, we estimated the numbers of soft infant and toddler carriers in use by assuming that a portion of caregivers, e.g., 25-50 percent, will continue to use carriers in the child's second year. Based on data from the 2006 Baby Products Tracking Study, approximately 2.1 million soft infant and toddler carriers are owned by new mothers. Assuming that 25-50 percent of caregivers continue to use soft infant and toddler carriers in the second year, approximately 2.6 million (2.1 million × 0.25 × 2.1 million) to 3.2 million (2.1 million × 0.50 × 2.1 million) households have soft infant and toddler carriers available for use annually. Based on Directorate for Epidemiology staff's estimate of 1,400 injuries treated nationally in emergency departments from 1999 to 2011, an average of about 108 emergency department-treated injuries involve soft infant and toddler carriers annually.[11] Therefore, about 0.34−0.40 emergency department-treated injuries may occur annually for every 10,000 soft infant and toddler carriers available for use.

C. Reason for Agency Action and Legal Basis for the Final Rule

The Danny Keysar Child Product Safety Notification Act, section 104 of the CPSIA, requires the CPSC to promulgate mandatory standards for nursery products that are substantially the same as, or more stringent than, the voluntary standard. Staff recommends adopting the voluntary standard (ASTM F2236-14), without modification.

D. Requirements of the Final Rule

The requirements of the final rule are set forth above in section V of this preamble, which describes ASTM F2236-14.

E. Issues Raised by Public Comments

Section IV of this preamble contains a summary of the five comments received and the issues raised by the comments.Start Printed Page 17431

F. Other Federal Rules

Two federal rules interact with the soft infant and toddler carrier mandatory standard: (1) Testing and Labeling Pertaining to Product Certification (16 CFR part 1107); and (2) Requirements Pertaining to Third Party Conformity Assessment Bodies (16 CFR part 1112). The regulation at 16 CFR part 1107 requires every manufacturer of a children's product that is subject to a children's product safety rule to certify, based on third party testing, that the product complies with all applicable safety rules. Because soft infant and toddler carriers will be subject to a mandatory children's product safety rule, they will also be subject to the third party testing requirements of 16 CFR part 1107 when the soft infant and toddler carrier mandatory standard becomes effective.

In addition, 16 CFR part 1107 requires the third party testing of children's products to be conducted by CPSC-accredited laboratories. Section 14(a)(3) of the CPSA required the Commission to publish a notice of requirements (NOR) for the accreditation of third party conformity assessment bodies (i.e., testing laboratories) to test for conformance with each children's product safety rule. The NORs for existing rules are set forth in 16 CFR part 1112. The Commission is finalizing an amendment to 16 CFR part 1112 that establishes the requirements for the accreditation of testing laboratories to test for compliance with the soft infant and toddler carrier final rule.

G. Impact on Small Businesses

The FRFA is limited to the 39 domestic firms known to be marketing soft infant and toddler carriers in the United States because U.S. Small Business Administration (SBA) guidelines and definitions pertain to U.S.-based entities. Under SBA guidelines, a manufacturer of soft infant and toddler carriers is small if it has 500 or fewer employees, and importers and wholesalers are considered small if they have 100 or fewer employees. Based on these guidelines, 32 of the 39 domestic firms supplying soft infant and toddler carriers to the U.S. market are small firms—18 manufacturers, six importers, and eight firms—whose supply source is unknown. Additional unknown small soft infant and toddler carrier suppliers may also operate in the U.S. market.

One purpose of the regulatory flexibility analysis is to evaluate the impact of a regulatory action and determine whether the impact is economically significant. While the SBA gives considerable flexibility in defining “economically significant,” CPSC staff typically uses one percent of gross revenue as the threshold for determining “economic significance.” CPSC staff considers any impact that is one percent or more of gross revenue is considered economically significant. SBA has accepted the one percent of gross revenue threshold and this threshold is also commonly used by agencies in determining economic significance.[12]

Small Manufacturers: The expected impact of the final rule on small manufacturers will differ, based on whether manufacturers' soft infant and toddler carriers are already compliant with F2236-13. Although F2236-14 was published in January 2014, firms are still likely to be testing to F2236-13. However, because ASTM F2236-13, ASTM F2236-13a, and ASTM F2236-14 do not contain material differences, manufacturers in compliance with ASTM F2236-13 are likely to continue to comply with the voluntary standard.

The Juvenile Products Manufacturers Association (JPMA), the major U.S. trade association that represents juvenile product manufacturers and importers, has certified several soft infant and toddler carriers as compliant with the voluntary standard, and other manufacturers have claimed compliance with the voluntary standard. Based on this information, 11 of 18 domestic manufacturers comply with ASTM F2236-13. These 11 firms should not require any modifications to their products and, as such, the firms should not be impacted by incorporation of ASTM F2236-14 as the final rule.

Meeting ASTM F2236-14's requirements could require some modifications for seven of the 18 domestic manufacturers who are believed not to be currently compliant with ASTM F2236-13. Based upon past discussions with firms and Engineering Sciences staff, necessary modifications would likely involve adding or changing straps, fasteners, or fabrics and generally would be less expensive to accomplish than a complete product redesign. Therefore, in most cases, the impact of the final rule is not expected to have a significant effect on products that do not comply with ASTM F2236-13.

Under section 14 of the CPSA, soft infant and toddler carriers are also subject to third party testing and certification requirements. Once the new soft infant and toddler requirements become effective, all manufacturers will be subject to the additional costs associated with the third party testing and certification requirements under the testing rule, Testing and Labeling Pertaining to Product Certification (16 CFR part 1107). Third party testing will pertain to any physical and mechanical test requirements specified in the soft infant and toddler carrier final rule; lead and phthalates testing is already required. Third party testing costs are in addition to the direct costs of meeting the soft infant and toddler standard.

Based on information from the durable nursery product industry and confidential business information supplied for the development of the third party testing rule, CPSC staff estimates that testing to a single ASTM voluntary standard could cost around $500-$600 per model sample. On average, each small domestic manufacturer supplies two different models of soft infant and toddler carriers to the U.S. market annually. Therefore, if third party testing to the requirements in the soft infant and toddler standard is conducted every year on a single sample for each model, third party testing costs associated for each manufacturer would be about $1,000-$1,200 annually. Based on an examination of estimates of firms' revenues from recent Dun & Bradstreet reports, the impact of third party testing is not likely to be economically significant if only one sample per model is required. However, if more than one sample is needed to meet the testing requirements, third party testing costs could have an economically significant impact on some small manufacturers (i.e., testing costs could be one percent or more of gross revenue). CPSC staff does not know exactly how many samples each manufacturer will need to test to meet the “high degree of assurance” criterion required by 16 CFR part 1107.

Small Importers: Most importers will not experience significant impacts as a result of the final rule. CPSC staff believes that four of the six small importers are compliant with the voluntary standard. The remaining importers may need to find an alternate source of soft infant and toddler carriers if their existing suppliers do not come into compliance with the requirements of the final rule. Alternatively, the firms may discontinue importing soft infant and toddler carriers altogether and perhaps substitute another juvenile product.

As is the case with manufacturers, all importers will be subject to third party Start Printed Page 17432testing and certification requirements, and consequently, they will experience the associated costs, if their supplying foreign firm(s) does not perform third party testing. The resulting costs could potentially have a significant impact on a few small importers that must perform the testing themselves, particularly if more than one sample per model is required.

Eight small firms have unknown supply sources, three of which appear to be compliant with ASTM F2236-13 and should not be impacted by the incorporation of ASTM F2236-14 as the mandatory final rule. The remaining five firms may need to make small changes to their products to be compliant with ASTM F2236-14. Due to the nature of the product, the modifications should be limited to changes in straps or fasteners and should not have a significant impact.

H. Alternatives

One alternative would be to set an effective date for the final rule later than the staff-recommended 6 months, which is generally considered sufficient time for suppliers to come into compliance with a durable infant and toddler product rule. Setting a later effective date would allow suppliers additional time to modify and/or develop compliant soft infant and toddler carriers and spread the associated costs over a longer period of time. However, given that the changes to meet the standard are not substantial, CPSC staff believes that 6 months is sufficient.

VIII. Environmental Considerations

The Commission's regulations address whether we are required to prepare an environmental assessment or an environmental impact statement. If our rule has “little or no potential for affecting the human environment,” the rule will be categorically exempted from this requirement. 16 CFR 1021.5(c)(1). The final rule for soft infant and toddler carriers falls within the categorical exemption.

IX. Paperwork Reduction Act

This rule contains information collection requirements that are subject to public comment and review by the Office of Management and Budget (OMB) under the Paperwork Reduction Act of 1995 (44 U.S.C. 3501-3520). The preamble to the proposed rule (78 FR at 20520 through 20521) discussed the information collection burden of the proposed rule and specifically requested comments on the accuracy of our estimates. OMB has assigned control number 3041-0162 to this information collection. We did not receive any comment regarding the information collection burden of the proposal. However, the final rule makes modifications regarding the information collection burden because the number of estimated manufacturers subject to the information collection burden is now estimated at 54 manufacturers rather than the 39 manufacturers initially estimated in the proposed rule.

Accordingly, the estimated burden of this collection of information is modified as follows:

Table 1—Estimated Annual Reporting Burden

16 CFR section Number of respondents Frequency of responses Total annual responses Hours per response Total burden hours 1226 54 2 108 1 108 Our estimate is based on the following:

Section 8.1 of ASTM F2236-14 requires that all soft infant and toddler carrier products and their retail packaging be marked or labeled as follows: the manufacturer, distributor, or seller name, and either the place of business (city, state, mailing address, including zip code), or telephone number, or both; and a code mark or other means that identifies the date (month and year as a minimum) of manufacture.

CPSC is aware of 54 firms that supply soft infant and toddler carriers in the U.S. market. For PRA purposes, we assume that all 54 firms use labels on their products and on their packaging already. However, firms might need to make some modifications to their existing labels. We estimate that the time required to make these modifications is about 1 hour per model. Each of the 54 firms supplies an average of two different models of soft infant and toddler carriers. Therefore, we estimate the burden hours associated with labels to be 108 hours annually (1 hour × 54 firms × 2 models per firm = 108 hours annually).

We estimate the hourly compensation for the time required to create and update labels is $27.71 (U.S. Bureau of Labor Statistics, “Employer Costs for Employee Compensation,” September 2013, Table 9, total compensation for all sales and office workers in goods-producing private industries: http://www.bls.gov/ncs/). Therefore, we estimate the annual cost to industry associated with the labeling requirements in the final rule to be $2,992.68 ($27.71 per hour × 108 hours = $2,992.68). This collection of information does not require operating, maintenance, or capital costs.

In compliance with the Paperwork Reduction Act of 1995 (44 U.S.C. 3507(d)), we have submitted the information collection requirements of this final rule to the OMB.

X. Preemption

Section 26(a) of the CPSA, 15 U.S.C. 2075(a), provides that where a consumer product safety standard is in effect and applies to a product, no state or political subdivision of a state may either establish or continue in effect a requirement dealing with the same risk of injury unless the state requirement is identical to the federal standard. Section 26(c) of the CPSA also provides that states or political subdivisions of states may apply to the Commission for an exemption from this preemption under certain circumstances. Section 104(b) of the CPSIA refers to the rules to be issued under that section as “consumer product safety rules,” thus implying that the preemptive effect of section 26(a) of the CPSA applies to final durable infant and toddler product final rules. Therefore, the final rule issued under section 104 of the CPSIA will invoke the preemptive effect of section 26(a) of the CPSA when the final rule becomes effective.

XI. Certification and Notice of Requirements

Section 14(a) of the CPSA requires that products subject to a consumer product safety rule under the CPSA, or to a similar rule, ban, standard or regulation under any other act enforced by the Commission, must be certified as complying with all applicable CPSC-enforced requirements. 15 U.S.C. 2063(a). Section 14(a)(2) of the CPSA requires that certification of children's products subject to a children's product Start Printed Page 17433safety rule be based on testing conducted by a CPSC-accepted third party conformity assessment body. Section 14(a)(3) of the CPSA requires the Commission to publish a NOR for the accreditation of third party conformity assessment bodies (or laboratories) to assess conformity with a children's product safety rule to which a children's product is subject. The final rule for 16 CFR part 1226, “Safety Standard for Soft Infant and Toddler Carriers,” is a children's product safety rule that requires the issuance of a NOR.

Effective June 10, 2013, the Commission published a final rule, Requirements Pertaining to Third Party Conformity Assessment Bodies, 78 FR 15836 (March 12, 2013), which codifies 16 CFR part 1112. Part 1112 establishes requirements for accreditation of third party conformity assessment bodies (or laboratories) to test for conformance with a children's product safety rule in accordance with Section14(a)(2) of the CPSA. The final rule also codifies all of the NORs that the CPSC has published, to date. All new NORs, such as the soft infant and toddler carrier standard, require an amendment to part 1112. Accordingly, the final rule amends part 1112 to include the soft infant and toddler standard, along with the other children's product safety rules for which the CPSC has issued NORs. The final NOR is based on the CPSC's laboratory accreditation requirements on the performance standard set forth in the final rule for the safety standard for soft infant and toddler carriers and the test methods incorporated within this standard.

Laboratories applying for acceptance as a CPSC-accepted third party conformity assessment body to test to the new standard for soft infant and toddler carriers are required to meet the third party conformity assessment body accreditation requirements in part 1112. When a laboratory meets the requirements as a CPSC-accepted third party conformity assessment body, the laboratory can apply to the CPSC to have 16 CFR part 1226, Safety Standard for Soft Infant and Toddler Carriers, included in the laboratory's scope of accreditation of CPSC safety rules listed for the laboratory on the CPSC Web site at: www.cpsc.gov/labsearch.

A FRFA was conducted as part of the promulgation of the original 16 CFR part 1112 (78 FR 15836, 15855-15858), as required by the Regulatory Flexibility Act. Briefly, the FRFA concluded that the accreditation requirements would not have a significant adverse impact on a substantial number of small laboratories because no requirements were imposed on laboratories that did not intend to provide third party testing services. The only laboratories expected to provide such services are those that anticipate receiving sufficient revenue from the mandated testing to justify accepting the requirements as a business decision.

Based on similar reasoning, amending the rule to include the NOR for the soft infant and toddler carrier standard will not have a significant adverse impact on small laboratories. Moreover, based upon the number of laboratories in the United States that have applied for CPSC acceptance of the accreditation to test for conformance to other juvenile product standards, we expect that only a few laboratories will seek CPSC acceptance of their accreditation to test for conformance with the soft infant and toddler carrier standard. Most of these laboratories have already been accredited to test for conformance to other juvenile product standards, and the only cost to them would be the cost of adding the soft infant and toddler standard to their scope of accreditation. As a consequence, the Commission certifies that the NOR for the soft infant and toddler carrier standard will not have a significant impact on a substantial number of small entities.

Start List of SubjectsList of Subjects

16 CFR Part 1112

- Administrative practice and procedure

- Audit

- Consumer protection

- Reporting and recordkeeping requirements

- Third party conformity assessment body

16 CFR Part 1226

- Consumer protection

- Imports

- Incorporation by reference

- Infants and Children

- Labeling

- Law Enforcement, and Toys

For the reasons discussed in the preamble, the Commission amends Title 16 of the Code of Federal Regulations by amending part 1112 and adding a new part 1226, as follows:

Start PartPART 1112—REQUIREMENTS PERTAINING TO THIRD PARTY CONFORMITY ASSESSMENT BODIES

End Part Start Amendment Part1. The authority citation for part 1112 continues to read as follows:

End Amendment Part Start Amendment Part2. In § 1112.15 add paragraph (b)(37) to read as follows:

End Amendment PartStart Amendment PartWhen can a third party conformity assessment body apply for CPSC acceptance for a particular CPSC rule and/or test method?* * * * *(b) * * *

(37) 16 CFR part 1226, Safety Standard for Soft Infant and Toddler Carriers.

* * * * *3. Add Part 1226 to read as follows:

End Amendment Part Start PartPART 1226—SAFETY STANDARD FOR SOFT INFANT AND TODDLER CARRIERS

Scope.This part establishes a consumer product safety standard for soft infant and toddler carriers.

End Part Start SignatureRequirements for soft infant and toddler carriers.(a) Each soft infant and toddler carrier must comply with all applicable provisions of ASTM F2236-14, Standard Consumer Safety Specification for Soft Infant and Toddler Carriers, approved on January 1, 2014. The Director of the Federal Register approves this incorporation by reference in accordance with 5 U.S.C. 552(a) and 1 CFR part 51. You may obtain a copy from ASTM International, 100 Bar Harbor Drive, P.O. Box 0700, West Conshohocken, PA 19428; http://www.astm.org/cpsc.htm. You may inspect a copy at the Office of the Secretary, U.S. Consumer Product Safety Commission, Room 820, 4330 East West Highway, Bethesda, MD 20814, telephone 301-504-7923, or at the National Archives and Records Administration (NARA). For information on the availability of this material at NARA, call 202-741-6030, or go to: http://www.archives.gov/federal_register/code_of_federal regulations/ibr_locations.html.

(b) [Reserved]

End Signature End Supplemental InformationDated: March 24, 2014.

Todd A. Stevenson,

Secretary, Consumer Product Safety Commission.

Footnotes

1. CPSC's NEISS database is a national probability sample of hospitals in the United States and its territories. Patient information is collected from each NEISS hospital for every emergency visit involving an injury associated with consumer products. From this sample, the total number of product-related injuries treated in hospital emergency rooms nationwide can be estimated.

Back to Citation2. According to CPSC Human Factors staff, this scenario represents an unsafe sleep environment. The prone sleep position is a known risk factor for SIDS, and placing an infant to sleep face down on top of a bed may increase the risk of suffocation. Sleeping in the prone position on a bed with an infant still inside a carrier may further increase the suffocation risk.

Back to Citation3. All of the fall incidents were emergency department-treated injury (NEISS data) reports.

Back to Citation4. Finish-related issues concern items such as material smoothness and lead content.

Back to Citation5. According to the NEISS publication criteria, an estimate must be 1,200 or greater, the sample size must be 20 or greater, and the coefficient of variation must be 33 percent or smaller.

Back to Citation6. Staff conducted research to identify manufacturers and importers of soft carriers. From the time of the NPR to the final rule, several firms entered the market, raising the number of suppliers from 39 in the NPR to 54 presently.

Back to Citation7. CPSC staff made these determinations using information from Dun & Bradstreet and ReferenceUSAGov, as well as the firms' Web sites.

Back to Citation8. The data collected for the Baby Products Tracking Study does not represent an unbiased statistical sample. The sample of 3,600 new and expectant mothers is drawn from American Baby magazine's mailing lists. Also, because the most recent survey information is from 2005, the information may not reflect the current market.

Back to Citation9. The data on secondhand products for new mothers was not available. Instead, data for new mothers and experienced mothers were combined and broken down into first-time mothers and experienced mothers. Data for first-time mothers and experienced mothers have been averaged to calculate the approximate percentage of soft infant and toddler carriers that were handed down or purchased secondhand.

Back to Citation10. U.S. Department of Health and Human Services, Centers for Disease Control and Prevention (CDC), National Center for Health Statistics, National Vital Statistics System, “Births: Final Data for 2009,” National Vital Statistics Reports Volume 60, Number 1 (November 2011): Table I. The number of live births in 2009 is rounded from 4,130,665.

Back to Citation11. Memorandum from Risana Chowdhury, Directorate for Epidemiology, dated March 11, 2013, Subject: Soft Infant and Toddler Carrier-Related Deaths, Injuries, and Potential Injuries, and NEISS Injury Estimates; 1999-September 10, 2012. CPSC staff cannot present national emergency department-treated injury estimates for 2012 due to insufficient numbers of NEISS incidents reported during the time period, and 2013 data is not yet available. Memorandum from Risana Chowdhury, Directorate for Epidemiology, dated September 23, 2013, Subject: Soft Infant and Toddler Carrier-Related Deaths, Injuries, and Potential Injuries between September 11, 2012 and July 15, 2013.

Back to Citation12. U.S. Small Business Administration, Office of Advocacy. A Guide for Government Agencies: How to Comply with the Regulatory Flexibility Act and Implementing the President's Small Business Agenda and Executive Order 13272. May 2012, pgs. 18-20. http://www.sba.gov/sites/default/files/rfaguide_0512_0.pdf.

Back to Citation[FR Doc. 2014-06771 Filed 3-27-14; 8:45 am]

BILLING CODE 6355-01-P

Document Information

- Effective Date:

- 9/29/2014

- Published:

- 03/28/2014

- Department:

- Consumer Product Safety Commission

- Entry Type:

- Rule

- Action:

- Final rule.

- Document Number:

- 2014-06771

- Dates: