|

Code of Federal Regulations (Last Updated: November 8, 2024) |

|

Title 30 - Mineral Resources |

|

Chapter I - Mine Safety and Health Administration, Department of Labor |

|

SubChapter B - Testing, Evaluation, and Approval of Mining Products |

|

Part 18 - Electric Motor-Driven Mine Equipment and Accessories |

|

Subpart D - Machines Assembled With Certified or Explosion-Proof Components, Field Modifications of Approved Machines, and Permits To Use Experimental Equipment |

Appendix II to Subpart D of Part 18

-

Appendix II to Subpart D of Part 18

LIST OF FIGURES

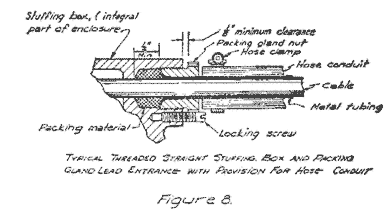

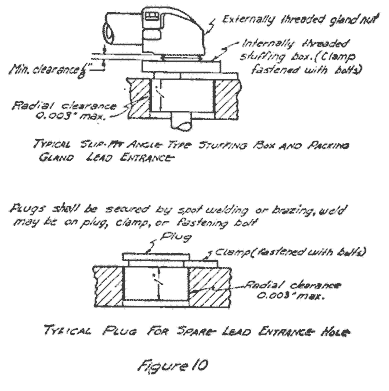

Figure No. Title 1 Typical layout drawing of a machine. 2 Sample bill of material (to accompany layout drawing shown on figure 1) 3 Material to be included with the operating instructions on or with the wiring diagram submitted to each customer. 4 Sample factory inspection form. 5 Typical plane joint. 6 Typical combination joint. 7 Typical threaded joint. 8 Typical threaded straight stuffing box and packing gland lead entrance with provision for hose conduit. 9 Typical slip-fit straight-type and angle-type stuffing box and packing gland lead entrance. 10 Typical slip-fit angle-type stuffing box and packing gland lead entrance and typical plug for spare lead entrance hole.

Figure 2 - Sample Bill of Material

B. of M. No. ________

Date ____________

Revision

Date

1. ____________

2. ____________

3. ____________

4. ____________

5. ____________

Bill of Material (Electrical)

(Manufacturing Company)

Model:

(Unit Name)

Approval 2G-

Motor:

(Manufacturing Company)

Frame

______ Hp., ______ Volts, ______ Ph.,

______ Cy., ______ R.P.M.

X/P____________________(Date).

____________(Date) Extension.

Starter:

(Manufacturing Company)

Model

________Hp., ________Volts.

X/P(Date)

____________ Extension.

(Date)Cable - Motor to Starter:

Cond. No. ______, ______″

O.D., ______′ Long

Hose - Motor to Starter Cable:

______″ I.D., ______″ O.D., ______ ′ Long

Portable (Trailing) Cable -

Type:

Cond. No. ______, ______″

O.D., ______′ Long

Hose - for Portable Cable:

______″ I.D., ______″ O.D., ______′ Long

Hose Clamps -

2 for Motor-Starter Hose conduit ______″ D

1 for Portable Cable Hose conduit ____″ D*

*Only when short length of hose is used. Trolley Tap -

(Manufacturing Company)

Model ____________________________ with ______-ampere fuse.

Rail Clamps, 2.

1 Ground Clamp, Cat. No. ______

(Manufacturing Company)

1 Return Power Conductor, Cat. No. ______

(Manufacturing Company)

or - as OptionalPlug on outby end of potable cable for insertion into receptacle on distribution box or equivalent with short-circuit protective device set at ______ amperes.

Static-free Belt

Model

Style

Catalog No. ______,

(Manufacturing Company)

Guard for Belt -

Material

Overall Dimensions ______″ Long × ______″

Wide × ______″ High

Note:The foregoing is intended as a guide. Additional electrical components used shall be completely identified.

Figure 3 - Material To Be Included With the Operating Instructions - on or With the Wiring Diagram Submitted to Each Customer

(Sometimes referred to as “Caution Statement”)

caution

To retain “permissibility” of this equipment the following conditions shall be satisfied:

1. General safety. Frequent inspection shall be made. All electrical parts, including the portable cable and wiring, shall be kept in a safe condition. There shall be no openings into the casings of the electrical parts. A permissible distribution box shall be used for connection to the power circuit unless connection is made in fresh intake air. To maintain the overload protection on direct-current machines, the ungrounded conductor of the portable cable shall be connected to the proper terminal. The machine frame shall be effectively grounded. The power wires shall not be used for grounding except in conjunction with diode(s) or equivalent. The operating voltage should match the voltage rating of the motor(s).

2. Servicing. Explosion-proof enclosures shall be restored to the state of original safety with respect to all flame arresting paths, lead entrances, etc., following disassembly for repair or rebuilding, whether by the owner or an independent shop.

3. Fastenings. All bolts, nuts, screws, and other means of fastening, and also threaded covers, shall be in place, properly tightened and secured.

4. Renewals and repairs. Inspections, repairs, or renewals of electrical parts shall not be made unless the portable cable is disconnected from the circuit furnishing power, and the cable shall not be connected again until all parts are properly reassembled. Special care shall be taken in making renewals or repairs. Leave no parts off. Use replacement parts exactly like those furnished by the manufacturer. When any lead entrance is disturbed, the original leads or exact duplicates thereof shall be used and stuffing boxes shall be repacked in the approved manner.

5. Cable requirements. A flame-resistant portable cable bearing a MSHA assigned identification number, adequately protected by an automatic circuit-interrupting device shall be used. Special care shall be taken in handling the cable to guard against mechanical injury and wear. Splices in portable cables shall be made in a workmanlike manner, mechanically strong, and well insulated. Not more than five temporary splices are permitted in a portable cable regardless of length. Connections and wiring to the outby end of the cable shall be in accordance with recognized standards of safety.

Figure 4 - Sample Factory Inspection Form

Date ____________

Inspector ________________________

machine

Designation:

Type: ____________ Serial No.

motor

Manufacturer:

Serial No.: ______ Type:

Frame:

Hp.____ F.L. Speed:____ Volts:____ Amps.__

Winding: ______ X/P No. ______ (or parts list designation).

starter

Manufacturer:

Serial No. ______ Type:

Hp. ______ Volts: ______ X/P No. ______ (or parts list designation).

Short-circuit protection ______ amps.

Overload-current protection ______ amps.

portable cable

Manufacturer: __________________________________

Type: ____________ Conductors: ______________

Length: ______ O.D. ______ MSHA No. ________

Is all wiring around machine adequately protected from mechanical damage?

By hose conduit__________, Troughs

Metal tubing __________, Other

By removal of all sharp corners or edges?

Is wiring separated from hydraulic components?

Is an adequate insulated strain clamp provided for the portable cable?

Are all packing glands properly packed so that 1⁄8-inch clearance remains between packing nut and stuffing box?

Are lockwashers (or equivalent) provided for all explosion-proof enclosure fastenings?

Are all plane joints securely fastened so that an 0.005-inch feeler gage cannot be inserted?

Are all threaded covers secured?

How?

Are all electrical connections secure ________and properly insulated where necessary?

Note:Add appropriate material for each explosion-proof enclosure when more than a motor and starter are on a machine.

[33 FR 4660, Mar. 19, 1968, as amended at 42 FR 8373, Feb. 10, 1977; 42 FR 25855, May 20, 1977]