-

Start Preamble

Start Printed Page 71894

AGENCY:

Office of Energy Efficiency and Renewable Energy, Department of Energy.

ACTION:

Supplemental notice of proposed rulemaking and corrections.

SUMMARY:

On January 18, 2013, the U.S. Department of Energy (DOE) issued a notice of proposed rulemaking (NOPR) to revise its test procedures for cooking products established under the Energy Policy and Conservation Act. The NOPR proposed a change to the test equipment that would allow for measuring the energy efficiency of induction cooking tops and ranges. To address issues raised in comments regarding the NOPR, DOE conducted additional research and analysis. In this supplemental notice of proposed rulemaking (SNOPR), DOE modifies its proposal to change the test equipment to allow for measuring the energy efficiency of induction cooking tops and proposes to add an additional test block size for electric surface units with large diameters (both induction and electric resistance). In addition, DOE proposes methods to test non-circular electric surface units, electric surface units with flexible concentric cooking zones, and full-surface induction cooking tops. In this SNOPR, DOE also proposes amendments to add a larger test block size to test gas surface units with higher input rates. DOE also proposes to incorporate methods for measuring conventional oven volume, to clarify that the existing oven test block must be used to test all ovens regardless of input rate, and to measure the energy consumption and efficiency of conventional ovens equipped with an oven separator. Additionally, DOE is proposing technical corrections to the units of measurement in certain calculations and the annual useful cooking energy output for gas cooktops.

DATES:

DOE will accept comments, data, and information regarding this NOPR no later than February 2, 2015. See section V, “Public Participation,” for details.

ADDRESSES:

Any comments submitted must identify the SNOPR for Test Procedures for conventional cooking products, and provide docket number EERE-2012-BT-TP-0013 and/or regulatory information number (RIN) 1904-AC71. Comments may be submitted using any of the following methods:

1. Federal eRulemaking Portal: http://www.regulations.gov. Follow the instructions for submitting comments.

2. Email: Induction-Cooking-Prod-2012-TP-0013@ee.doe.gov. Include the docket number and/or RIN in the subject line of the message.

3. Mail: Ms. Brenda Edwards, U.S. Department of Energy, Building Technologies Program, Mailstop EE-5B, 1000 Independence Avenue SW., Washington, DC 20585-0121. If possible, please submit all items on a CD. It is not necessary to include printed copies.

4. Hand Delivery/Courier: Ms. Brenda Edwards, U.S. Department of Energy, Building Technologies Program, 950 L'Enfant Plaza SW., Suite 600, Washington, DC 20024. Telephone: (202) 586-2945. If possible, please submit all items on a CD. It is not necessary to include printed copies.

For detailed instructions on submitting comments and additional information on the rulemaking process, see section V of this document (Public Participation).

Docket: The docket, which includes Federal Register notices, public meeting attendee lists and transcripts, comments, and other supporting documents/materials, is available for review at regulations.gov. All documents in the docket are listed in the regulations.gov index. However, some documents listed in the index, such as those containing information that is exempt from public disclosure, may not be publicly available.

A link to the docket Web page can be found at: http://www.regulations.gov/#!docketDetail;dct=FR+PR+N+O+SR+PS;rpp=50;so=DESC;sb=postedDate;po=0;D=EERE-2012-BT-TP-0013. This Web page will contain a link to the docket for this notice on the regulations.gov site. The regulations.gov Web page will contain simple instructions on how to access all documents, including public comments, in the docket. See section V for information on how to submit comments through regulations.gov.

For further information on how to submit a comment or review other public comments and the docket, contact Ms. Brenda Edwards at (202) 586-2945 or by email: Brenda.Edwards@ee.doe.gov.

Start Further InfoFOR FURTHER INFORMATION CONTACT:

Ms. Ashley Armstrong, U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, Building Technologies Program, EE-5B, 1000 Independence Avenue SW., Washington, DC 20585-0121. Telephone: (202) 586-6590. Email: ashley.armstrong@ee.doe.gov.

Ms. Celia Sher, U.S. Department of Energy, Office of the General Counsel, GC-71, 1000 Independence Avenue SW., Washington, DC 20585-0121. Telephone: (202) 202-287-6122. Email: Celia.Sher@hq.doe.gov.

End Further Info End Preamble Start Supplemental InformationSUPPLEMENTARY INFORMATION:

Table of Contents

I. Authority and Background

A. General Test Procedure Rulemaking Process

B. Test Procedures for Cooking Products

C. The January 2013 NOPR

D. The February 2014 RFI

II. Summary of the Supplemental Notice of Proposed Rulemaking and Corrections

III. Discussion

A. Products Covered by This Test Procedure Rulemaking

1. Induction Cooking Products

2. Gas Cooking Products With High Input Rates

B. Effective Date

C. Conventional Cooking Top Active Mode Test Procedure

1. Test Block Construction

2. Water-Heating Test Method

3. Test Block Sizes

4. Non-Circular and Flexible Surface Units

5. Improved Heat Transfer Within the Hybrid Test Block

6. Expected Cooking Top Performance

7. Clarification of the Reduced Energy Input Setting

D. Gas Cooking Products With High Input Rates

1. Surface Units With Input Rates Greater Than 14,000 Btu/h

2. Gas Ovens With Input Rates Greater Than 22,500 Btu/h

E. Incorporating by Reference AHAM-OV-1-2011 for Determination of the Volume of Conventional Ovens

F. Conventional Oven Separator

G. Standby and Off Mode Test Procedure

H. Technical Corrections to the Calculation of Derived Results From Test Measurements

I. Headings for Conventional Cooking Top Calculations

J. Compliance With Other EPCA Requirements

IV. Procedural Issues and Regulatory Review

A. Review Under Executive Order 12866

B. Review Under the Regulatory Flexibility Act

C. Review Under the Paperwork Reduction Act of 1995

D. Review Under the National Environmental Policy Act of 1969

E. Review Under Executive Order 13132

F. Review Under Executive Order 12988

G. Review Under the Unfunded Mandates Reform Act of 1995

H. Review Under the Treasury and General Government Appropriations Act, 1999

I. Review Under Executive Order 12630

J. Review Under Treasury and General Government Appropriations Act, 2001

K. Review Under Executive Order 13211Start Printed Page 71895

L. Review Under Section 32 of the Federal Energy Administration Act of 1974

V. Public Participation

A. Submission of Comments

B. Issues on Which DOE Seeks Comment

1. Hybrid Test Blocks

2. Typical Cookware Thickness

3. Additional Test Block Size for Electric Resistance and Induction Surface Units

4. Non-Circular and Flexible Electric Surface Units

5. Thermal grease characteristics

6. Clarification of the Reduced Energy Input Setting

7. Gas Cooking Top Surface Units with Input Rates >14,000 Btu/h

8. Gas Ovens with High Input Rates

9. Test Method to Measure Oven Cavity Volume

10. Test Method for Conventional Ovens with an Oven Separator

11. Technical Corrections

VI. Approval of the Office of the Secretary

I. Authority and Background

Title III of the Energy Policy and Conservation Act of 1975 (42 U.S.C. 6291, et seq.; “EPCA” or, “the Act”) sets forth a variety of provisions designed to improve energy efficiency. (All references to EPCA refer to the statute as amended through the American Energy Manufacturing Technical Corrections Act (AEMTCA), Pub. L. 112-210 (Dec. 18, 2012).) Part B of title III, which for editorial reasons was re-designated as Part A upon incorporation into the U.S. Code (42 U.S.C. 6291-6309, as codified), establishes the “Energy Conservation Program for Consumer Products Other Than Automobiles.” These include residential kitchen ranges and ovens, the subject of this SNOPR. (42 U.S.C. 6292(a)(10))

Under EPCA, the energy conservation program consists essentially of four parts: (1) Testing, (2) labeling, (3) Federal energy conservation standards, and (4) certification and enforcement procedures. The testing requirements consist of test procedures that manufacturers of covered products must use as the basis for (1) certifying to DOE that their products comply with the applicable energy conservation standards adopted under EPCA, and (2) making representations about the efficiency of those products. Similarly, DOE must use these test procedures to determine whether the products comply with any relevant standards promulgated under EPCA.

A. General Test Procedure Rulemaking Process

Under 42 U.S.C. 6293, EPCA sets forth the criteria and procedures DOE must follow when prescribing or amending test procedures for covered products. EPCA provides in relevant part that any test procedures prescribed or amended under this section shall be reasonably designed to produce test results which measure energy efficiency, energy use or estimated annual operating cost of a covered product during a representative average use cycle or period of use and shall not be unduly burdensome to conduct. (42 U.S.C. 6293(b)(3))

In addition, if DOE determines that a test procedure amendment is warranted, it must publish proposed test procedures and offer the public an opportunity to present oral and written comments on them. (42 U.S.C. 6293(b)(2)) Finally, in any rulemaking to amend a test procedure, DOE must determine to what extent, if any, the proposed test procedure would alter the measured energy efficiency of any covered product as determined under the existing test procedure. (42 U.S.C. 6293(e)(1))

B. Test Procedures for Cooking Products

DOE's test procedures for conventional ranges, conventional cooking tops, conventional ovens, and microwave ovens are codified at appendix I to subpart B of Title 10 of the Code of Federal Regulations (CFR) part 430 (Appendix I).

DOE established the test procedures in a final rule published in the Federal Register on May 10, 1978. 43 FR 20108, 20120-28. These test procedures did not cover induction cooking products because they were, at the time, relatively new products, and represented a small share of the market. 43 FR 20117. DOE revised its test procedures for cooking products to more accurately measure their efficiency and energy use, and published the revisions as a final rule in 1997. 62 FR 51976 (Oct. 3, 1997). These test procedure amendments did not address induction cooking, but included: (1) A reduction in the annual useful cooking energy; (2) a reduction in the number of self-cleaning oven cycles per year; and (3) incorporation of portions of International Electrotechnical Commission (IEC) Standard 705-1988, “Methods for measuring the performance of microwave ovens for household and similar purposes,” and Amendment 2-1993 for the testing of microwave ovens. Id. The test procedures for conventional cooking products establish provisions for determining estimated annual operating cost, cooking efficiency (defined as the ratio of cooking energy output to cooking energy input), and energy factor (defined as the ratio of annual useful cooking energy output to total annual energy input). 10 CFR 430.23(i); Appendix I. These provisions for conventional cooking products are not currently used for compliance with any energy conservation standards because the present standards only regulate design requirements, nor is there an EnergyGuide [1] labeling program for cooking products.

DOE subsequently conducted a rulemaking to address standby and off mode energy consumption, as well as certain active mode testing provisions, for residential dishwashers, dehumidifiers, and conventional cooking products. DOE published a final rule on October 31, 2012 (77 FR 65942, hereinafter referred to as the October 2012 Final Rule), adopting standby and off mode provisions that satisfy the EPCA requirement that DOE include measures of standby mode and off mode energy consumption in its test procedures for residential products, if technically feasible. (42 U.S.C. 6295(gg)(2)(A))

C. The January 2013 NOPR

On January 30, 2013, DOE published a NOPR (78 FR 6232, hereinafter referred to as the January 2013 NOPR) proposing amendments to Appendix I that would allow for testing the active mode energy consumption of induction cooking products; i.e., conventional cooking tops and ranges equipped with induction heating technology for one or more surface units [2] on the cooking top. DOE proposed to incorporate induction cooking tops by amending the definition of “conventional cooking top” to include induction heating technology. Furthermore, DOE proposed to require for all cooking tops the use of test equipment compatible with induction technology. Specifically, DOE proposed to replace the solid aluminum test blocks currently specified in the test procedure for cooking tops with hybrid test blocks comprising two separate pieces: An aluminum body and a stainless steel base. Appendix I currently specifies the test block size for electric cooking tops based on the surface unit diameter; however, there are no provisions for determining which test block size to use for non-circular electric surface units. In the January 2013 NOPR, DOE also proposed amendments to include a clarification that the test block size be determined using the smallest dimension of the electric surface unit. 78 FR 6232, 6234 (Jan. 30, 2013).

Start Printed Page 71896D. The February 2014 RFI

On February 12, 2014, DOE published a request for information (RFI) (79 FR 8337, hereinafter referred to as the February 2014 RFI) to initiate an effort to determine whether to amend the current energy conservation standards for conventional cooking products. As part of the February 2014 RFI, DOE stated that it tentatively plans to consider energy conservation standards for all consumer conventional cooking products, including commercial-style gas cooking products [3] and standard gas cooking products that have burners with higher input rates. These products were not included in the analysis underlying the previous standards rulemaking due to a lack of data upon which to determine the measurement of energy efficiency for these products. 79 FR 8337, 8341 (Feb. 12, 2014); 74 FR 16040, 16054 (Apr. 8, 2009). Because DOE is tentatively planning to consider energy conservation standards for all gas cooking products, including those with high input rate cooking tops and ovens, DOE is also considering amending the cooking products test procedure in Appendix I to include methods for measuring the energy consumption of these products as part of the SNOPR.

II. Summary of the Supplemental Notice of Proposed Rulemaking and Corrections

Based on review of the public comments received in response to the January 2013 NOPR and the potential for considering additional product types in future energy conservation standards rulemakings for conventional cooking products as discussed in the February 2014 RFI, DOE conducted further analysis in support of the proposals discussed in this SNOPR.

DOE continues to propose a hybrid test block comprising a stainless steel base and aluminum body for conventional cooking top testing, including conventional cooking tops with induction heating technology. Further testing conducted by DOE at multiple test laboratories indicated that this test block type produces repeatable and reproducible results. For comparison, DOE also conducted additional water-heating tests at multiple test laboratories, but found the results to be less repeatable and reproducible than the hybrid block-heating tests, consistent with the results discussed in the January 2013 NOPR. 78 FR 6232, 6240-41 (Jan. 30, 2013). DOE's testing, however, showed that adding a layer of thermal grease improves the thermal contact between the base and body of the test block and results in thermal behavior of the test block that is more representative of real-world cooking vessels. Therefore, in this SNOPR, DOE proposes to require the application of thermal grease between the stainless steel base and aluminum body to improve thermal contact between the two parts. The proposed thermal grease would be required to have a thermal conductivity of at least 1.73 British thermal units per hour per foot per degree Fahrenheit (Btu/hr-ft-°F) (1.0 watts per meter per degree Kelvin (W/m-K)).[4]

In its additional investigative testing, DOE determined that the existing test block diameters, 6.25 inches and 9 inches, may not be appropriate for testing conventional electric cooking top surface units with large diameters. For large-diameter electric surface units, the 9-inch test block typically results in lower measured efficiencies when compared to a larger test block with a diameter that may more accurately reflect consumer use. To address this issue, DOE proposes a 10.5-inch diameter hybrid test block for testing electric cooking top surface units with diameters of at least 10 inches.

In the January 2013 NOPR, DOE proposed that test block selection for non-circular electric cooking top surface units be based on the surface unit's shortest dimension. 78 FR 6232, 6241 (Jan. 30, 2013). Based on stakeholder feedback and a review of the market, DOE has revised its proposal to address the different types of units available on the market. In the SNOPR, DOE proposes that for electric cooking tops: (1) Test blocks for non-circular surface units be selected based on the surface unit's shortest dimension; (2) surface units with flexible concentric sizes (i.e., units with multiple zones of the same shape but varying shortest dimensions) shall be tested at each unique size setting; and (3) full-surface induction cooking tops with “cook anywhere” functionality be tested with all three test block sizes in the center of the usable cooking surface. DOE also clarifies in the SNOPR that for all cooking tops, specialty surface units such as bridge zones, warming plates, grills, and griddles, are not covered by Appendix I.

DOE also proposes a clarification to the cooking top test procedure in Appendix I to specify that the maximum energy input rate, as referenced in section 3.1.2 of Appendix I, shall be the average energy input rate determined over the duration of the test period at the maximum setting. The average energy input rate determined over the duration of the test period at the reduced setting shall be 25 ± 5 percent of the maximum energy input rate.

Additionally, DOE is proposing amendments that would allow for testing the active mode energy consumption of gas cooking tops with higher surface unit input rates. Based on investigative testing of these cooking tops using a range of test block sizes to represent larger food loads and cookware diameters, DOE proposes that all gas surface units rated above 14,000 Btu/h be tested using a 10.5-inch hybrid test block. For gas ovens, investigative testing of larger oven test blocks for use in ovens with higher input rates did not suggest that the oven test block size should be modified. Thus, DOE proposes that the existing oven test block be used to test all ovens, including ovens having input rates greater than 22,500 Btu/h.

As discussed in the February 2014 RFI, DOE is considering amending the standards for conventional cooking products. As part of any amended standards for conventional ovens, DOE may propose standards as a function of oven cavity volume. Because Appendix I does not currently contain a measure of conventional oven volume, DOE considered methodology for determining this value. Based on DOE's review of the Association of Home Appliance Manufacturers (AHAM) Standard OV-1-2011 “Procedures for the Determination and Expression of the Volume of Household Microwave and Conventional Ovens” (AHAM-OV-1-2011), DOE tentatively concludes that this test method provides a repeatable and reproducible method for measuring conventional oven cavity volume. As a result, DOE is proposing in the SNOPR to incorporate by reference the relevant sections of AHAM-OV-1-2011 for determining conventional oven cavity volume in the DOE test procedure.

Based on DOE's review of products available on the market, DOE is additionally proposing test methods for Start Printed Page 71897conventional ovens equipped with an oven separator that allows for cooking using the entire oven cavity in the absence of the separator or, if the separator is installed, splitting the oven into two smaller cavities that may be operated individually with independent temperature controls. DOE is proposing in the SNOPR that conventional ovens equipped with an oven separator shall be tested in each possible oven configuration (i.e., full oven cavity, upper cavity, and lower cavity) with the results averaged.

DOE received comments from interested parties agreeing with its preliminary determination in the January 2013 NOPR that the existing definitions of standby mode and off mode do not require revision. 78 FR 6232, 6241 (Jan. 30, 2013). Therefore DOE is not proposing changes to these definitions in the supplemental proposal. Additionally, DOE did not observe any standby mode or off mode operation or features unique to induction cooking tops and cooking tops and ovens with high input rate burners tested in support of the SNOPR that would warrant changes to the standby mode and off mode test methods for conventional cooking tops. Id.

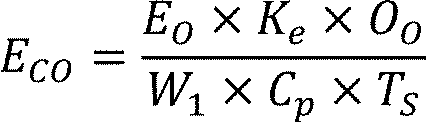

DOE is also proposing technical corrections to the calculation of derived results from test measurements in section 4 of Appendix I. Section 4 contains a number of references to incorrect units of measurement and an incorrect value for the annual useful cooking energy output for gas cooktops.

Finally, DOE noted that the headings for sections 4.2 and 4.2.1 in Appendix I regarding the calculations for conventional cooking tops were inadvertently removed. As a result, DOE is proposing to add the headings for section 4.2 “Conventional cooking top,” and section 4.2.1, “Surface unit cooking efficiency” to appropriately describe these sections.

III. Discussion

A. Products Covered by This Test Procedure Rulemaking

1. Induction Cooking Products

As discussed in section I of this notice, the test procedures currently in Appendix I do not apply to induction cooking products. In the January 2013 NOPR, DOE proposed to amend the definition of “conventional cooking top” to include products that feature electric inductive heating surface units. DOE noted that the definition of “conventional range” would remain unchanged but would include the cooking top component of a range that heats by means of induction technology. 78 FR 6232, 6234-35 (Jan. 30, 2013). DOE similarly proposed in the January 2013 NOPR to revise the definition of “active mode” included in Appendix I to account for electric inductive heating, consistent with the proposed definition of “conventional cooking top.” Id.

The Association of Home Appliance Manufacturers (AHAM) and BSH Home Appliances Corporation (BSH) commented that they do not oppose the proposed amended definitions of “conventional cooking top” or “active mode,” but do oppose the overall amendments to include inductive heating in the test procedure at this time. (AHAM, TP No. 7 at p. 2 [5] BSH, TP No. 8 at p. 2) AHAM and BSH stated that they do not believe DOE's proposed amendments to the test procedure allow for direct comparisons across cooking technologies, and claimed that because induction cooking tops and ranges do not heat the test block directly, the induction technology will be penalized. (AHAM, TP No. 7 at p. 2; BSH, TP No. 8 at p. 2) Natural Resources Defense Council (NRDC) supported the expansion of the cooking products test procedure to include induction cooking products, based on increased market availability of these products. (NRDC, TP No. 4, at p. 1) NRDC also urged DOE to ensure that its test procedures allow for comparisons of efficiency across product types (gas, electric resistance, and induction units) so that consumers are able to make informed decisions. (NRDC, TP No. 4 at p. 1)

From its testing in support of this rulemaking, DOE determined that the proposed amendments accurately compare the energy consumption of induction cooking tops with the energy consumption of other conventional cooking tops. Although induction cooking tops heat the hybrid test block differently compared to other conventional cooking tops, this manner of heating is representative of how food loads in pots or pans are heated during typical consumer use (i.e., the thermal energy is generated in the stainless steel base which represents the cookware, and then is transferred by conduction to the aluminum body which simulates the food load.) Additionally, DOE maintains the proposal that the hybrid test block be used to test all cooking top types (gas, electric resistance, and induction), which would allow for comparable efficiency measurements across all of the covered technologies.

2. Gas Cooking Products With High Input Rates

In the previous energy conservation standards rulemaking for conventional cooking products, DOE excluded “commercial-style” residential gas cooking products from its analysis in considering whether to adopt amended energy conservation standards, due to a lack of available data for determining efficiency characteristics of those products. DOE also noted that its cooking products test procedures may not adequately measure the performance of higher input rate burners. 74 FR 16040, 16054 (Apr. 8, 2009); 72 FR 64432, 64444-45 (Nov. 15, 2007). DOE considers a cooking top burner with a high input rate to be a burner rated greater than 14,000 Btu/h. Similarly, DOE considers gas ovens with high burner input rates to be those with burners rated greater than 22,500 Btu/h.

Based on investigative testing in support of this notice, DOE is proposing to amend the conventional cooking top test procedure in Appendix I to measure the energy use of gas surface units with high input rates and to clarify that the existing conventional oven test procedure is appropriate for ovens with high input rates. DOE notes that the current definitions for “conventional cooking top,” “conventional oven,” and “conventional range” in 10 CFR 430.2 already cover conventional gas cooking products with higher input rates (including commercial-style gas cooking products), as these products are household cooking appliances with surface units or compartments intended for the cooking or heating of food by means of a gas flame.

B. Effective Date

The amended test procedure would become effective 30 days after any test procedure final rule is published in the Federal Register. Pursuant to EPCA, manufacturers of covered products must use the applicable test procedure as the basis for determining that their products comply with the applicable energy conservation standards adopted pursuant to EPCA and for making representations about the efficiency of those products. (42 U.S.C. 6293(c); 42 U.S.C. 6295(s)) Beginning 180 days after publication of any test procedure final rule, representations related to the energy consumption of conventional cooking products must be based upon results generated under the applicable provisions of the amended test Start Printed Page 71898procedures in Appendix I. (42 U.S.C. 6293(c)(2))

C. Conventional Cooking Top Active Mode Test Procedure

The current active mode test procedure for conventional cooking tops involves heating an aluminum test block on each surface unit of the cooking top. Two aluminum test blocks, of different diameters, are specified for testing different size surface units. The small test block (6.25 inches diameter) is used for electric surface units with diameters of 7 inches or less, and the large test block (9 inches diameter) is used for electric surface units with diameters greater than 7 inches and all gas surface units. Once the initial test and ambient conditions are met, the surface unit is turned to its maximum energy input setting. After the test block temperature increases by 144 degrees Fahrenheit (°F), the surface unit input rate is immediately reduced to 25 percent ± 5 percent of the maximum energy input rate for 15 ± 0.1 minutes. The efficiency of the surface unit is calculated as the ratio of the energy transferred to the test block (based on its temperature rise) to the energy consumed by the cooking top during the test. The cooking top cooking efficiency is calculated as the average efficiency of the surface units on the cooking top. The current active mode test procedure is compatible with gas cooking tops and electric cooking tops with electric resistance heating elements (i.e., electric resistance heating under a smooth ceramic surface and open coil electric resistance heating).

1. Test Block Construction

Induction cooking products are compatible with only ferromagnetic cooking vessels because the high magnetic permeability of these vessels concentrates the induced current near the surface of the metal, increasing resistance and thus heating. Aluminum is not a ferromagnetic metal—its lower magnetic permeability allows the magnetic field to penetrate further into the material so that the induced current flows with little resistance, and thus does not heat up when it encounters an oscillating magnetic field. Therefore, the aluminum test blocks currently required by Appendix I are not appropriate for testing induction cooking products.

As part of the January 2013 NOPR, DOE conducted testing to investigate potential substitute test blocks for testing induction cooking products. DOE conducted tests using the same basic test method specified in Appendix I, as described above, using carbon steel, carbon steel hybrid, and stainless steel hybrid test blocks. 78 FR 6232, 6235 (Jan. 30, 2013). Table III.1 describes the construction of the current aluminum test blocks and the three substitute test blocks.

Table III.1—Test Block Composition Descriptions

Test block classification Test block composition (component and material) Aluminum One solid aluminum alloy 6061 block. Carbon Steel One solid carbon steel alloy 1018 block. Carbon Steel Hybrid Carbon steel alloy 1018 base + Aluminum alloy 6061 body. Stainless Steel Hybrid Stainless steel alloy 430 base + Aluminum alloy 6061 body. Based on its initial investigative testing, DOE observed that the stainless steel hybrid test block, hereinafter referred to as the hybrid test block, produced the most repeatable results, and proposed amending Appendix I to require these blocks for all cooking top testing. 78 FR 6232, 6235, 6241 (Jan. 30, 2013). DOE verified these initial conclusions through additional testing conducted for this SNOPR (see section III.C.1 through section III.C.4 of this notice), and further evaluated an improvement to the hybrid test block through the application of thermal grease between the stainless steel base and aluminum body (see section III.C.5 of this SNOPR.)

In response to the January 2013 NOPR, AHAM asked whether DOE had information on the typical thickness of a pot or pan, questioning the proposed thickness of the hybrid test block base at 0.25 inches. (AHAM, Public Meeting Transcript, TP No. 5 at p. 29) [6] Through a market search, DOE determined that the typical thickness of cookware compatible with induction cooking tops range from 20 gauge (~0.04 inch) to 8 gauge (~0.17 inch) depending on the type and application of the cookware.[7] Heavy-gauge pans have thicknesses as large as 8 or 9 millimeters (mm) (0.32 to 0.35 inch). Additionally, the IEC Standard 60350-2 Edition 1.0 “Household electric cooking appliances—Part 2: Hobs—Method for measuring performance” specifies test cookware with a base thickness of 6 mm (0.24 inch). DOE selected the 0.25-inch stainless steel base to reduce the impact of warping but still remain within the plausible thickness of a pot or pan, and to harmonize with the IEC cookware base (to the nearest common dimension in inches).

AHAM and BSH expressed concern that the results presented in the January 2013 NOPR were obtained using one laboratory and a single set of test blocks. (AHAM, TP No. 7 at p. 4; BSH, TP No. 8 at p. 4) AHAM and BSH asked whether DOE had examined whether warping of the blocks might impact their heat transfer. (AHAM, Public Meeting Transcript, TP No. 5 at p. 27; AHAM, TP No. 7 at pp. 2, 4; BSH, TP No. 8 at pp. 2, 4) AHAM and BSH emphasized that any change in the flatness of the test blocks, including between layers, whether due to construction or warping over time, could impact test results and increase variation from test to test as there might not be uniform contact between the block and the surface unit. AHAM and BSH requested that DOE study the impact of flatness on energy measurements to define technically feasible and consistent limits for flatness. (AHAM, TP No. 7, at pp. 3-4; BSH, TP No. 8 at pp. 3-4) AHAM and BSH also commented that the proposed flatness of 0.002 total indicator reading (TIR) is not technically feasible for the 9-inch diameter test block because it cannot be verified with commonly accepted laboratory equipment. Id.

DOE evaluated the amount of warping observed for both the stainless steel base and aluminum body of the 6.25-inch and 9-inch hybrid test blocks originally Start Printed Page 71899purchased for testing in support of the January 2013 NOPR. Each of these test blocks underwent approximately 100 tests. The aluminum body in both test block sizes remained within the 0.002 TIR tolerance specified in the existing test procedure. However, the stainless steel base for both the 6.25-inch and 9-inch test block did not remain within tolerance, resulting in a flatness greater than 0.002 TIR but less than 0.004 inch TIR after one year of use. The cooking tops evaluated for this test series included the test sample listed in Table III.2.

Table III.2—Cooking Top Test Sample

Cooking top unit designation Heating technology Surface unit designation Surface unit diameter Surface unit max rated power (W) A Smooth—Electric Resistance Front Right (FR) 9 3000 A Smooth—Electric Resistance Back Left (BL) 6 1200 B Coil—Electric Resistance Front Right (FR) 8 2350 B Coil—Electric Resistance Front Left (FL) 6 1500 C Smooth—Induction Back Right (BR) 10 3300 C Smooth—Induction Front Left (FL) 7 2400 D Smooth—Induction Front Right (FR) 11 3700 D Smooth—Induction Back Right (BR) 6 1800 E Gas Front Right (FR) a 9000 F Smooth—Electric Resistance Front Right (FR) 12 3000 F Smooth—Electric Resistance Back Left (BL) 8 2400 G Smooth—Electric Resistance Front Right (FR) 12 3000 G Smooth—Electric Resistance Back Left (BL) 6 1200 a Gas surface unit max rated power is in Btu/h. As part of the testing conducted for the SNOPR, DOE fabricated a new set of test blocks to evaluate the effects of potential warping and to evaluate the reproducibility of the test procedure between multiple test laboratories. DOE conducted tests with these new test blocks as well as additional tests with the original test blocks that exceeded the 0.002 inch TIR requirement. The results shown in Table III.3 provide a comparison between tests run with in-tolerance hybrid test blocks at Laboratory 1 and out-of-tolerance test blocks at Laboratory 2.

Table III.3—Block Warping Comparison of Measured Surface Unit Efficiency

Test block size Cooking top unit designation Heating technology Surface unit designation Mean efficiency (Laboratory 1 <0.002 inch TIR) (percent) Mean efficiency (Laboratory 2 <0.004 inch TIR) (percent) Difference in measured efficiency 9-inch Test Block B Coil—Electric Resistance FR 71.87 71.50 0.37 D Induction FR 73.59 72.63 0.96 6.25-inch Test Block B Coil—Electric Resistance FL 71.42 71.80 −0.39 D Induction BR 72.71 73.21 −0.50 The difference in the average measured surface unit efficiency between the test blocks in tolerance and out of tolerance and between the two test facilities is consistently less than 1 percent. Additionally, the out-of-tolerance test block measured efficiencies are not consistently higher or lower than the in-tolerance test block efficiencies, suggesting that the out-of-tolerance test blocks do not have a clear positive or negative effect on the measured efficiencies. Based on these results, DOE tentatively concludes that the hybrid test block produces results that are reproducible and that minor warping has a minimal effect on measured efficiency.

DOE proposes to maintain the current specified flatness of 0.002 inch TIR for the construction of both the aluminum body and stainless steel base of the hybrid test block. Based on the testing results showing that hybrid test block pieces having a flatness of 0.004 inch TIR or less will not greatly impact measured efficiency, DOE proposes that the stainless steel hybrid test blocks may continue to be used until their flatness exceeds 0.004 inch TIR. This will help reduce the burden associated with replacing the test blocks and ensuring they remain within the flatness tolerance. DOE expects that standard machine shops will likely have the ability to measure flatness within the specified tolerances.

AHAM and BSH also stated that larger test blocks may have an increased potential for warping that could lead to increased variation in the test results, especially if a larger test block will need to reach higher temperatures. (AHAM, TP No. 7 at p. 4; BSH, TP No. 8 at p. 4) AHAM and BSH suggested that larger test blocks may not be technologically feasible because there is likely no way to transfer the heat out of the block fast enough. Id. Additionally, AHAM and BSH suggested that as the temperature of the block increases, the heat loss increases, and could potentially result in an inaccurate measurement. (AHAM, TP No. 7 at p. 5; BSH, TP No. 8 at p. 5)

To address the concerns of the large test block reaching higher temperatures, DOE evaluated the final block temperatures observed for both the 6.25-inch and 9-inch test blocks. Figure III.1 correlates test block final temperature with surface unit rated power for induction, smooth—electric resistance, and coil—electric resistance cooking tops.

Start Printed Page 71900For a given, rated, surface unit power, final temperatures for the 6.25-inch test block were higher than for the 9-inch test block. Generally, the 9-inch test block does not reach significantly higher temperatures when compared to the 6.25-inch test block. Therefore, DOE does not expect any additional warping concerns or heat transfer issues for the 9-inch test block compared to the 6.25-inch test block.

AHAM and BSH noted that because AHAM members have seen variation in stainless steel composition within the same nominal steel type (e.g., differences in the amounts of carbon and chrome), DOE should study the impact of changes in the stainless steel composition on the surface unit efficiency measurement. (AHAM, TP No. 7 at p. 4; BSH, TP No. 8 at p.4)

DOE spoke with material suppliers during the test block fabrication process. Suppliers did not express any concern that magnetic or thermal properties might change from lot to lot of stainless steel alloy 430. Moreover, there is limited variation of the thermal properties even among different grades of stainless steel alloy. Thus, DOE does not anticipate any significant variation within a single grade of stainless steel 430. Additionally, DOE notes that the test results presented above in Table III.3 are based on test blocks purchased in different years. DOE expects that the blocks were manufactured from different lots of stainless steel and aluminum, yet even with the warping issues and testing at different labs, they still produced consistent results.

For the reasons described above, DOE proposes an additional clarification requiring that the block flatness of the hybrid test blocks must be maintained within 0.004 inch TIR for testing.

2. Water-Heating Test Method

For the January 2013 NOPR, DOE also conducted tests to heat water in standardized cooking vessels to compare test repeatability with the metal block-heating tests. DOE stated that water provides a heating medium that is more representative of actual consumer use because many foods cooked on a cooking top have a relatively high liquid content. However, DOE also noted that water heating introduces additional sources of variability not present for metal block heating—the temperature distribution in the water is not always uniform, the properties of the water can vary from laboratory to laboratory, and the ambient conditions and cookware surface effects can have a large impact on the water boiling and evaporating throughout the test. DOE conducted these water-heating tests using the test loads and test methods specified in a draft amendment to the IEC Standard 60350-2 Edition 1.0 “Household electric cooking appliances—Part 2: Hobs—Method for measuring performance” (Draft IEC 60350 Amendment) [9] with additional calculations to estimate the efficiency of the water-heating process. 78 FR 6232, 6239-40 (Jan. 30, 2013). On April 25, 2014, IEC made available the draft version of IEC Standard 60350-2 Edition 2.0 Committee Draft (IEC 60350-2 CD). DOE noted that the Draft IEC 60350 Amendment and IEC 60350-2 CD include the same basic test method.

AHAM and BSH commented that data presented in the January 2013 NOPR did not clearly identify the test block method as being preferable to the water-heating method for induction units and requested DOE perform an additional study to determine which method produces more accurate, repeatable, and reproducible results. (AHAM, TP No. 7 at p. 2; BSH, TP No. 8 at p. 2) AHAM and BSH also commented that they do not believe that the January 2013 NOPR sufficiently demonstrated the stainless steel hybrid test block as the best method for testing induction cooking tops, and that neither of the considered test methods emerged as a more repeatable and reproducible method. Specifically, AHAM and BSH noted that in the January 2013 NOPR, the results were split, with about half of the standard deviations being smaller for the hybrid test block and half being smaller for the water-heating method. Start Printed Page 71901(AHAM, TP No. 7 at pp. 3, 4; BSH, TP No. 8 at pp. 3, 4)

In preparation for the SNOPR, DOE performed additional tests to further evaluate the repeatability and reproducibility of the hybrid test block method as compared to the water-heating method. Table III.4 summarizes the test results from Laboratory 1 using the hybrid test blocks, the aluminum-only test blocks, and the IEC 60350-2 CD water loads. The test sample included two induction cooking tops, two conventional electric cooking tops, and one conventional gas cooking top. Because aluminum is not compatible with induction cooking, DOE only tested the aluminum blocks on the three conventional cooking tops in the test sample. The 6.25-inch diameter test load was used for electric surface units with diameters of 7 inches or less. The 9-inch diameter test load was used for electric surface units with diameters greater than 7 inches and all gas surface units, as required by Appendix I.

Table III.4—Laboratory 1 Mean Cooking Top Efficiency

Test load size Cooking top unit designation Heating technology Surface unit designation Mean efficiency (%) Hybrid Aluminum Water load Large a A Smooth—Electric Resistance FR 67.72 75.81 79.76 B Coil—Electric Resistance FR 71.87 79.83 79.98 C Induction BR 70.73 78.65 D Induction FR 73.59 80.49 E Gas FR 43.94 47.02 Small b A Smooth—Electric Resistance BL 66.22 71.01 70.44 B Coil—Electric Resistance FL 71.42 76.17 76.95 C Induction FL 69.43 79.16 D Induction BR 72.71 78.49 a Large = (9-inch for Hybrid Load and 9.45-inch for IEC Water Load). b Small = (6.25-inch for Hybrid Load and 5.91-inch for IEC Water Load). To investigate the laboratory-to-laboratory reproducibility of test results, DOE conducted testing in support of the SNOPR at two laboratories. Two of the units in the test sample were tested at both laboratories. At Laboratory 1, a set of ten tests were performed on each surface unit using the proposed hybrid test blocks and the IEC 60350-2 CD water-heating test method. At Laboratory 2, three tests were performed for each surface unit and each test method.[10] Table III.5 compares the measured efficiencies for the hybrid test blocks and the IEC 60350-2 CD water loads for the two cooking tops that were tested at both test laboratories.

Table III.5—Mean Cooking Top Efficiency Comparison Between Test Laboratories

Test block size Cooking top unit designation Heating technology Surface unit designation Hybrid mean efficiency Diff. (percent) Water load mean efficiency Diff. (percent) Lab 1 (percent) Lab 2 (percent) Lab 1 (percent) Lab 2 (percent) Large a B Coil—Electric Resistance FR 71.87 71.50 0.37 79.98 79.22 0.76 D Induction FR 73.59 72.63 0.96 80.49 81.51 −1.02 Small b B Coil—Electric Resistance FL 71.42 71.80 −0.39 76.95 76.80 0.15 D Induction FL 72.71 73.21 −0.50 78.49 81.67 −3.18 a Large = (9-inch for Hybrid Load and 9.45-inch for IEC Water Load). b Small = (6.25-inch for Hybrid Load and 5.91-inch for IEC Water Load). As discussed in section III.C.1 and shown in Table III.5, the hybrid test blocks produced reproducible results at the two test laboratories. The IEC 60350-2 CD test load also produced similar results between the two test laboratories, with a slightly greater difference in efficiencies compared to the hybrid test blocks for the two induction surface units.

To assess the repeatability of the two test loads, Table III.6 compares the standard deviations for each surface unit tested at Laboratory 1 with both the water-heating and hybrid block-heating tests. As shown in Table III.4, the water-heating tests generally result in higher measured efficiencies compared to the hybrid tests. To account for the higher standard deviations that may be associated with higher measured efficiencies, Table III.6 also includes the coefficient of variation for each set of tests.

Table III.6—Test Method Standard Deviations

Test load size Cooking top unit designation Heating technology Surface unit designation Standard deviation (%) Coefficient of variation Hybrid Water load Hybrid Water load Lab 1: Large A Smooth—Electric Resistance FR 0.57 3.05 0.008 0.039 Start Printed Page 71902 B Coil—Electric Resistance FR 1.05 2.15 0.015 0.027 C Induction BR 0.74 0.66 0.011 0.008 D Induction FR 1.02 0.57 0.014 0.007 Small A Smooth—Electric Resistance BL 1.26 3.03 0.019 0.044 B Coil—Electric Resistance FL 2.01 1.50 0.028 0.020 C Induction FL 1.63 2.22 0.023 0.029 D Induction BR 1.34 0.64 0.019 0.008 Lab 2: Large B Coil—Electric Resistance FR 0.39 0.37 0.004 0.004 D Induction FR 0.24 0.71 0.003 0.008 Small B Coil—Electric Resistance FL 0.48 4.58 0.005 0.052 D Induction FL 0.31 1.30 0.003 0.015 As shown in Table III.6, the proposed DOE test method produced standard deviations of just over 2 percent or less for each surface unit. Conversely, standard deviations for the IEC 60350-2 CD water-heating test method exceeded 3 percent for some tested surface units, and ranged as high as 4.58 percent. The average standard deviation for the proposed DOE test method across induction units was 0.60 percent for the 9-inch test block and 0.94 percent for the 6.25-inch test block. The average standard deviation across all induction units for the water-heating method was 0.58 percent for the large IEC cookware and 2.19 percent for the small IEC cookware.

Because DOE is proposing the use of the hybrid test block for all surface unit types, DOE also considered the standard deviation across all surface unit types for each test method. The average standard deviation for the proposed DOE test method across all test surface units was 0.67 percent for the 9-inch test block and 1.17 percent for the 6.25-inch block. The average standard deviation across all surface unit types for the water-heating method was 1.25 percent for the large IEC cookware and 2.21 percent for the small IEC cookware. Similarly, the coefficients of variation for the hybrid tests were, on average, lower than for the water-heating tests. The average coefficient of variation across all surface unit types was 0.009 for the 9-inch test block and 0.016 for the 6.25-inch block, while the average coefficients of variation of the large and small IEC cookware were 0.016 and 0.028, respectively.

The water-heating test variability could potentially be reduced by imposing more stringent tolerances on the ambient conditions than Appendix I requires. Ambient air pressure, temperature, and humidity significantly impact the amount of water that evaporates during the test and the temperature at which the water begins to boil. Appendix I, however, only specifies ambient air temperature, and its relatively large tolerance, 77 °F ± 9 °F, could contribute to increased test variability. However, AHAM and BSH also noted that if DOE were to adopt tighter ambient controls, it could require considerable financial investment to construct or modify a test facility to meet these requirements, depending on the limits identified. Test blocks also lose heat to the ambient air and the impact of heat loss could cause variation in test results. (AHAM, TP No. 7 at p. 6; BSH, TP No. 8 at p. 6)

The water-heating tests under the current DOE test conditions do not show an improvement in test-to-test repeatability or laboratory-to-laboratory reproducibility compared to the hybrid block-heating tests across all surface unit types. For induction cooktops alone, the repeatability and reproducibility of the hybrid test block are sufficiently small. Because DOE seeks to implement a single test method applicable to all surface unit types, and because achieving reduced ambient temperature tolerances and adding humidity and pressure tolerances per IEC 60350-2 CD would potentially place a high burden on manufacturers, DOE maintains its proposal to use hybrid test blocks for all products covered under the proposed definition of conventional cooking tops and is not proposing any amendments to the existing ambient test conditions in Appendix I.

In the January 2013 NOPR, DOE indicated that it developed additional calculations to estimate the efficiency of the water-heating process in order to account for the amount of water that evaporated or boiled off. 78 FR 6232, 6240 (Jan. 30, 2013). AHAM and BSH commented that it is inappropriate to calculate efficiency with a water-heating test precisely because it is always unknown how much water evaporates during the test. (AHAM, TP No. 7 at p. 5; BSH, TP No. 8 at p. 5) AHAM and BSH also claimed they cannot fully or meaningfully evaluate the results DOE presented in the notice of proposed rulemaking because those results are based on energy efficiency, not consumption. AHAM and BSH requested that DOE provide energy consumption data to stakeholders and also analyze the energy consumption data itself in order to properly evaluate the accuracy, repeatability, and reproducibility of the water-heating test. AHAM and BSH suggested that it is possible that the standard deviations could be different if energy consumption results are evaluated instead of energy efficiency results and might indicate that the water-heating test is more reproducible and/or repeatable than the hybrid block test procedure. (AHAM, TP No. 7 at p. 5; BSH, TP No. 8 at p. 5)

Table III.7 and Table III.8 list the standard deviations and coefficients of variation for the energy consumption measured for the cooking tops in the test sample using the IEC 60350-2 CD water-heating test method and the proposed DOE test block. Data collected for both the January 2013 NOPR and this SNOPR were used to calculate the standard deviations and coefficients of variation presented in Table III.7 and Table III.8.Start Printed Page 71903

Table III.7—Water-Heating Test Load Energy Consumption Repeatability

Test load size Cooking top unit designation Heating technology Surface unit designation Average test energy consumption (Wh) Standard deviation (Wh) Coefficient of variation Large A Smooth—Electric Resistance FR 550.93 10.14 0.02 B Coil—Electric Resistance FR 533.05 12.25 0.02 C Induction BR 455.96 20.94 0.05 D Induction FR 522.06 7.14 0.01 Small A Smooth—Electric Resistance BL 230.78 1.67 0.01 B Coil—Electric Resistance FL 241.41 5.60 0.02 C Induction FL 247.44 3.67 0.02 D Induction BR 226.41 9.01 0.04 Table III.8—Proposed DOE Test Block Energy Consumption Repeatability

Test load size Cooking top unit designation Heating technology Surface unit designation Average test energy consumption (Wh) Standard deviation Coefficient of variation Large A Smooth—Electric Resistance FR 560.3 11.65 0.02 B Coil—Electric Resistance FR 456.77 6.49 0.01 C Induction BR 379.37 3.26 0.01 D Induction FR 453.27 12.58 0.03 Small A Smooth—Electric Resistance BL 225.84 8.1 0.04 B Coil—Electric Resistance FL 231.6 10.54 0.05 C Induction FL 226.95 3.48 0.02 D Induction BR 210.56 3.93 0.02 Consistent with testing in support of the January 2013 NOPR, DOE found that energy consumption using the IEC 60350-2 CD water-heating test method is not a more repeatable or reproducible metric than cooking efficiency for evaluating cooking top performance. The results based on energy consumption resulted in an average coefficient of variation 0.024 for the water-heating test method, which is similar to the average coefficient of variation for cooking top water-heating efficiency (0.022). Energy consumption as measured with the proposed DOE test block resulted in an average coefficient of variation of 0.025 which is similar to the variation observed using the water-heating test method. In turn, these coefficients of variation are both higher than the average coefficient of variation for cooking efficiency using the hybrid test block (0.0125 on average for both test block sizes). DOE observed that a specific turndown setting would not always maintain the appropriate simmering temperature from test to test. Accordingly, adjustments to the turndown setting between tests were necessary to meet the simmering requirements. These differences in the turndown setting resulted in a wide range of measured energy consumptions. DOE noted that these differences in the reduced settings corresponded to varying amounts of water boiled or evaporated off during the test. Accordingly, DOE developed efficiency calculations that address this variation, which factor in: (a) The total temperature rise of the water to account for differences in simmering temperatures, and (b) the total amount of water lost to boiling or evaporation during the test by measuring the mass of the cookware plus water at the start and end of the test. However, even with these adjustments, the test results with DOE's water-heating efficiency calculations are still less repeatable than the hybrid block-heating tests. For these additional reasons, DOE continues to propose the block-heating test method using the hybrid test blocks.

3. Test Block Sizes

AHAM and BSH noted that because induction coils do not reach full power unless the test block covers the entire surface unit, two test blocks might not be sufficient. According to AHAM and BSH, many use and care guides instruct consumers to match the pot or pan to the size of the coil. Therefore, AHAM and BSH stated that in order for an induction cooking top test procedure to be representative of actual consumer use, the test blocks must fully cover the surface unit. (AHAM, TP No. 7 at p. 4; BSH, TP No. 8 at p. 4)

DOE tested four electric surface units covering a range of diameters using both the 6.25-inch and 9-inch test blocks. The test results evaluated the effects of either oversizing (using the 9-inch test block on a smaller surface unit) or under-sizing (using the 6.25-inch test block on a larger surface unit) the test block relative to the surface unit as shown in Table III.9.

Table III.9—Difference in Efficiencies Measured With 9-Inch and 6.25-Inch Test Blocks

Cooking top unit designation Heating technology Surface unit designation Surface unit diameter (inches) 6.25-inch block measured efficiency (%) 9-inch block measured efficiency (%) Measured efficiency difference (%) C Induction FL 7 69.43 71.39 1.96 A Smooth—Electric Resistance BL 6 66.22 71.25 5.03 F a Smooth—Electric Resistance FR 12 33.17 58.95 25.78 Start Printed Page 71904 F a Smooth—Electric Resistance BL 8 49.61 72.87 23.26 a Cooking top F was added to the test sample to investigate block sizing but was not included in the repeatability results as it was not tested for the January 2013 NOPR. Results showed that for surface units with diameters up to 7 inches, the difference in measured efficiency between the 9-inch test block and the 6.25-inch test block was on average less than 3.5 percent and within the typical test-to-test variation. However, for surface unit diameters exceeding the small test block diameter by 1.75 inches or more, differences in measured efficiency were on the order of 25 percent. These results show that as the difference between test block diameter and surface unit diameter increases, an undersized test block would reduce measured cooking efficiency for surface units with larger diameters. The results do not show a similar effect for oversizing the test block. While it is not possible to undersize the test block on an induction surface unit because internal controls sense the cookware diameter to protect the unit from misuse, oversizing the test block does not greatly affect current generation in the base of the hybrid test block based on DOE testing, and resulted in similar measured efficiencies between the 6.25-inch and 9-inch block. For smooth cooking tops with electric resistance heating, when the test block is undersized, heat from the surface unit's heating element that exceeds the test block diameter is transferred to the ambient air. When oversized, the entire smooth heating element serves to heat the test block with only limited heat transfer back to the cooktop surface.

Based on a review of the market, DOE found that electric cooking top surface unit diameters typically reach up to 12 inches. In determining an appropriate test block size for these larger surface units, DOE noted that the hybrid test block proposed for use with gas cooking tops with higher surface unit input rates, as described in section III.D.1 below, had the appropriate diameter to capture the range of large electric surface units in the residential market. Selecting this test block for use with large electric surface units would also minimize manufacturer burden because the two test blocks proposed for use with gas cooking tops could be used to test electric cooking tops. Table III.10 contains efficiencies measured with the 10.5-inch test block for four surface units greater than 10 inches in diameter.

Table III.10—Difference in Efficiencies Measured With 10.5-Inch and 9-Inch Test Blocks

Cooking top unit designation Heating technology Surface unit designation Surface unit diameter (inches) 9-inch block measured efficiency (%) 10.5-inch block measured efficiency (%) Measured efficiency difference (%) A Smooth—Electric Resistance FL 12 52.95 56.07 3.12 F a Smooth—Electric Resistance FR 12 58.95 63.04 4.09 G a Smooth—Electric Resistance FR 12 57.09 71.22 14.13 a Cooking tops F and G were added to the test sample to investigate block sizing but were not included in the repeatability results as it was not tested for the January 2013 NOPR. Results indicated that efficiencies measured with the 10.5-inch test block are higher than those measured with the 9-inch test block. However, because the difference in size between the two blocks is less than the difference in size between the 6.25-inch and 9-inch test block, the efficiency increase is not as significant.

Table III.11 lists the dimensions and thermal properties of the three proposed hybrid test blocks.

Table III.11—Hybrid Test Block Specifications

Test block size Block diameter (inches) Block height (inches) Block weight (pounds (lb)) Specific heat (Btu/lb-°F) Heat capacity (Btu/°F) Small Stainless Steel Base 6.25 0.25 2.15 0.11 0.24 Small Aluminum Body 6.25 2.5 7.46 0.23 1.72 Small Total 6.25 2.75 9.61 0.20 1.96 Medium Stainless Steel Base 9 0.25 4.28 0.11 0.47 Medium Aluminum Body 9 2.72 16.85 0.23 3.87 Medium Total 9 2.97 21.13 0.21 4.34 Large Stainless Steel Base 10.5 0.25 6.09 0.11 0.67 Large Aluminum Body 10.5 3.48 29.39 0.23 6.76 Start Printed Page 71905 Large Total 10.5 3.73 35.48 0.21 7.43 DOE also investigated how test block size might affect surface unit power during the test to determine if surface unit input rate was dependent on test block diameter. By testing certain surface units with both the 6.25-inch and 9-inch test blocks, DOE was able to compare the average energy input rate and maximum power during the heat-up period (i.e., the period at the maximum setting) for the different block sizes. Table III.12 compares the average and maximum power during the heat-up period for the two current test block sizes on four surface units.

Table III.12—Energy Input Rate at the Maximum Setting

Cooking top unit designation Heating technology Surface unit designation Surface unit diameter (inches) Test block size Average power at max setting (W) Maximum power (W) A Smooth—Electric Resistance BL 6 6.25-inch 1211.3 1344 A Smooth—Electric Resistance BL 6 9-inch 1065.0 1317.6 A Smooth—Electric Resistance FR 9 6.25-inch 2894.6 3218 A Smooth—Electric Resistance FR 9 9-inch 2644.2 3210 D* Induction BR 6 6.25-inch 1878.5 2052 D* Induction BR 6 9-inch 1458.6 2105 * Cooking Top D was tested with thermal grease, which is discussed further in section III.C.5, to determine a more representative maximum power level for induction cooking tops. For smooth—electric resistance cooking tops, based on DOE's testing, the maximum power level for the smooth cooking top was not affected by the presence of thermal grease. These test results show that for each surface unit tested, the average power during the heat-up period for the 6.25-inch test block is higher than for the 9-inch test block, even when the test block is significantly undersized. However, the maximum instantaneous power measured at the maximum setting on average shows no significant difference between the two test block sizes. Based on these results showing that both test block sizes allow surface units to reach the same maximum power, DOE determined that the proposed test block sizes are appropriate.

4. Non-Circular and Flexible Surface Units

In the January 2013 NOPR, DOE proposed that for non-circular surface units, the appropriate test block size would be determined based on the surface unit's shortest dimension. 78 FR 6232, 6241 (Jan. 30, 2103). AHAM asked whether DOE had conducted any testing on the non-circular types of surface units or considered how different sizes of hybrid test blocks might impact the results. (AHAM, Public Meeting Transcript, TP No. 5 at p. 41) AHAM and BSH also stated that while DOE's test block proposal would address rectangular or oval-shaped surface units, it would not address surface elements that are not clearly defined. According to these commenters, there is a current trend in the market to have flexible cooking zones—i.e., those that do not have clearly defined edges. AHAM and BSH requested that DOE develop a procedure that would allow units with flexible cooking zones to be accurately tested. (AHAM, TP No. 7 at p. 6; BSH, TP No. 8 at p. 6)

Based on a review of products on the market, DOE is aware of full-surface induction cooking tops with no clearly defined cooking zones. These cooking tops have multiple smaller inductors underneath the cooking top surface, which are fully or partially energized depending on the size of the cookware. Because the inductors are typically all the same size and distributed evenly across the cooking surface, DOE does not expect efficiency to vary significantly with location on the cooking surface. However, efficiency may vary with the different test block sizes. For these units with no clear surface unit markings, consumers may use any size cookware on the cooking top. To ensure testing covers the range of heating loads that may be used, DOE proposes that these full-surface cooking tops be tested with each of the proposed hybrid test block sizes (6.25-inch, 9-inch, and 10.5-inch diameters). Each test block would be tested separately by placing the block in the center of the usable induction surface and following the same proposed test method for testing individual surface units. The center of the usable induction surface may be offset from the geometric center of the cooking top because full-surface controls and displays may be embedded in the surface of the cooking top, reducing the usable induction surface available for cooking. DOE proposes that each test block would be centered so that it is equidistant from any boundaries of the usable induction surface, including boundaries due to the placement of the controls or display. The efficiency of the cooking top would be the average of the measured efficiencies using each of test blocks.

DOE measured the efficiency of a single full-surface induction cooking top to evaluate the proposed test method. Table III.13 displays measured efficiency in the center of the cooking top as well as the standard deviation of four tests per test block, run at different positions on the cooking top (center, right of center, back left, and front left).Start Printed Page 71906

Table III.13—Full-Surface Induction Cooking Top Measured Efficiency

Hybrid test block diameter Measured efficiency at the center of the cooking top (%) Standard deviation of off-center measurements (%) 6.25-inch 65.84 1.85 9-inch 66.14 2.77 10.5-inch 71.32 2.42 Changing test block position did not have a significant effect on measured efficiency, but the standard deviations resulting from changing position were higher than the standard deviations measured with a hybrid test block on a standard induction cooking top. Specifying test block position is necessary to ensure repeatability. Furthermore, the average efficiency, as measured with the three test blocks, is 67.77 percent.

Many smooth—electric resistance cooking tops have “multi-ring” elements that have multiple concentric heating elements for a single surface unit. When a single ring is energized, this corresponds to the smallest diameter surface unit available. When two rings are energized, the diameter of the surface unit increases. This continues for as many concentric heating elements as are available for the surface unit. Multiple heating elements give the user flexibility to adjust the surface unit to fit a certain cookware size. Because each heating element can typically be controlled independently, DOE conducted tests on multi-ring elements to determine if the different control settings result in different measured efficiencies. Table III.14 lists the measured efficiencies for the multi-ring surface units on two smooth—electric resistance cooking tops.

Table III.14—Multi-Ring Smooth—Electric Resistance Cooking Top Efficiency

Cooking top unit designation Heating technology Surface unit designation Surface unit size (inches) Number of rings energized Size of largest energized ring (inches) Test block size (inches) Cooking efficiency (percent) A Smooth—Electric Resistance FR 9 Dual Single 9 6 9 6.25 67.7 59.2 F Smooth—Electric Resistance FR 12 Triple Dual Single 12 9 6 10.5 9 6.25 71.9 66.7 57.8 F Smooth—Electric Resistance BL 8 Dual Single 8 5 9 6.25 72.9 62.8 For each of the multi-ring surface units, the largest-diameter setting (i.e., the setting using all available rings) resulted in the highest measured efficiencies. Each surface unit showed a significant decrease in efficiency at the smaller-diameter settings, up to 14.1 percentage points. Because of the observed differences in efficiency at the different surface unit settings, DOE proposes that each distinct diameter setting for a multi-ring surface unit be tested as a separate surface unit. For example, if the surface unit has three settings with outer diameters of 12, 9, and 6 inches, each setting would be tested separately with the appropriately sized test block, and the results would be factored in to the overall cooking top efficiency calculation as if they were individual surface units.

DOE is aware of other non-circular electric cooking top elements such as bridge zones, warming plates, grills and griddles that are not intended for use with a typical circular piece of cookware. Appropriate test blocks for these heating elements would depend on the intended function of each surface unit. DOE expects that specifying and requiring additional test blocks for these specific heating elements would place an unreasonable burden on test laboratories and manufacturers. Additionally DOE expects use of these types of surface units to be much less frequent than the standard surface units used for circular pots and pans. DOE notes that some gas cooking tops may also be equipped with warming plates, grills and griddles that are not intended solely for use with a typical piece of circular cookware. As a result, DOE is not proposing to require testing of gas warming plates, grills, and griddles in determining cooking top efficiency.

5. Improved Heat Transfer Within the Hybrid Test Block

In response to the January 2013 NOPR, AHAM and BSH commented that the proposed description of test block construction was ambiguous and requested that construction be clearly defined so as to limit laboratory-to-laboratory variation in test results. AHAM and BSH also asked whether a bonding agent should be used to join the aluminum and stainless steel pieces or if test technicians should layer one piece on top of the other without bonding. Furthermore, AHAM and BSH asked whether DOE had performed testing to see whether adding a bonding agent led to more repeatable and reproducible results. (AHAM, TP No. 7 at p. 3; BSH, TP No. 8 at p. 3)

In addition to questions regarding the construction of the test block, AHAM and BSH asked whether DOE had examined the heat transfer between the stainless steel base and aluminum body of the hybrid test block. (AHAM, Public Meeting Transcript, TP No. 5 at p. 27; AHAM, TP No. 7 at pp. 2, 4; BSH, TP No. 8 at pp. 2, 4) During recent manufacturer interviews conducted as part of a separate rulemaking to consider amended energy conservation standards for conventional cooking products, manufacturers stated that any small imperfections in the contacting surfaces of the hybrid test block, due to warping or machining, leave an air gap between the base and body of the hybrid test block which may result in poor thermal contact between the two layers. Start Printed Page 71907According to manufacturers, the proposed test block construction may not produce test results that are typical of consumer use (e.g., boiling water).

For the January 2013 NOPR, the aluminum body and stainless steel base of the hybrid test blocks were machined from extruded bar stock, and the aluminum body was placed on top of the stainless steel base for each test. No bonding agent was used to join the base and body of the hybrid blocks because DOE observed that the weight and resulting friction kept the aluminum body firmly fixed to the base throughout the duration of the test. However, because stakeholders expressed concern over the thermal contact between the stainless steel base and aluminum body, DOE investigated the effect of applying a layer of thermal grease between the two pieces. Thermal grease is not a permanent bonding agent, but its high viscosity and thermal conductivity ensures good contact between the base and body of the hybrid test block, filling any surface imperfections.

DOE liberally applied a layer of silver-based thermal grease to the stainless steel base, using the aluminum body to apply pressure and spread the grease evenly across the surface of the base until there was complete coverage of the contacting surface of each piece. The thermal conductivity of the selected grease was approximately 1.73 Btu/hr-ft-°F (1.0 W/m-K).

Figure III.2 shows the initial temperature rise of the hybrid test block on an induction surface unit both with and without thermal grease when tested according to Appendix I. As noted above, Appendix I requires that the surface unit be set to its maximum power setting during the initial temperature rise. Once the test block temperature reaches 144 °F above the starting temperature, the control power setting is turned down. The turndown is reflected in the figure as a change in the rate of temperature increase.[11] Figure III.2 also includes the temperature rise of a boiling water load for comparison. All three tests were performed on the 6-inch diameter back right induction surface unit of cooking top D.

The rate of temperature increase during the initial temperature rise of the hybrid test block changes significantly with the addition of thermal grease and closely resembles the initial temperature rise of the water load as shown in Figure III.2. This change suggests that by adding thermal grease, the hybrid test block method may be more representative of actual cooking top usage than the test block without thermal grease. DOE observed similar changes in the rate of temperature increase for larger test block sizes and for all types of cooking tops.

DOE investigated the impact on measured efficiency and repeatability of varying the quantity of thermal grease as well as varying the application technique. An example application technique included applying the grease in an “X” shape near the center of the stainless steel base and applying pressure with the aluminum body to spread the grease evenly across the base. Alternate techniques included applying the grease in a line and spreading the Start Printed Page 71908grease with a spackling knife. Table III.15 contains the average efficiency and standard deviation for multiple runs with each application technique. Regardless of the application technique or grease quantity, thick, even application of the grease yielded similar results. Nineteen investigative thermal grease tests performed on a single induction surface unit, 6 inches in diameter, resulted in an overall standard deviation of 1.43%.

Table III.15—Effect of Variation in Thermal Grease Application on Efficiency for Cooking Top D

Application type Number of tests per application Average efficiency (percent) Standard deviation (percent) X-shape, 12 grams (g) 3 70.90 0.75 Spread evenly with spackling knife, 7g 2 68.94 1.05 X-shape, 10g 3 68.93 0.08 Spread evenly with spackling knife, 12g 6 69.99 0.57 Spread evenly with spackling knife, 10g 5 71.67 0.08 Average for all runs 19 70.30 1.43 After conducting these tests, DOE separated the hybrid test block pieces and observed that the amount of thermal grease listed in Table III.16 produced an even layer that fully covered the surface between the test blocks. After six tests with a test block, DOE also noted that the thermal grease had dried out and had to be removed and replaced.

Table III.16—Thermal Grease Quantity Required for Even Test Block Coverage

Hybrid test block diameter (inches) Quantity of thermal grease (g) 6.25 10-12 9 20-25 10.5 28-34 For the reasons discussed above, DOE proposes to amend Appendix I to require, in addition to the hybrid test block configuration proposed in the January 2013 NOPR, that a layer of thermal grease be applied to evenly cover the surface between the stainless steel base and the aluminum body of the hybrid test block for all test block sizes. The amount of thermal grease applied would be dependent on the test block diameter, according to the quantities listed in Table III.16. The thermal grease would be required to have a thermal conductivity of at least 1.73 Btu/hr-ft-°F (1.0 W/m-K). DOE also proposes to require the use of this modified hybrid test block for all conventional cooking tops and for the cooking top component of all conventional ranges. This will allow measured efficiency to be comparable across product classes and will also reduce manufacturer burden by not requiring additional test block configurations.

6. Expected Cooking Top Performance

AHAM and BSH commented that the test block method in general may not be representative of actual consumer use, especially for induction technology. AHAM and BSH requested that DOE consider the amount of time consumers typically spend cooking a food load to capture any potential energy efficiency benefits to induction technology in the short term (e.g., heating-up phase of cooking) that might even out across technologies as cooking time increases (e.g., simmering). According to AHAM and BSH, energy use and efficiency for cooking products is a function of a consumer's individual cooking behavior, and consumer use of cooking products varies from person to person. (AHAM, TP No. 7 at p. 2; BSH, TP No. 8 at p. 2)

As discussed in section III.C.5, comparing the initial temperature rise of the hybrid test block with thermal grease to the initial temperature rise of water suggests that the test block method is representative of real-world cooking vessel heating. The initial heat-up period at the maximum energy input rate setting as specified in Appendix I is determined based on test block temperature, not a specified time, so if a certain technology achieves the initial temperature rise more quickly (e.g., with less energy to reach that state,) the test procedure would reflect that in a higher cooking efficiency. To examine performance of the heat-up period independent of the simmering period, DOE calculated surface unit efficiency for only the initial temperature rise of 144 °F. Due to changes in product availability over the course of the testing performed for the SNOPR, DOE selected additional cooking tops to evaluate with the thermal grease. Table III.17 provides an updated list of tested surface units for this investigation.

Start Printed Page 71909Table III.17—Cooking Top Surface Units Evaluated With Thermal Grease