-

Start Preamble

AGENCY:

Consumer Product Safety Commission.

ACTION:

Notice of proposed rulemaking.

SUMMARY:

The Danny Keysar Child Product Safety Notification Act, section 104 of the Consumer Product Safety Improvement Act of 2008 (“CPSIA”), requires the United States Consumer Product Safety Commission (“Commission” or “CPSC”) to promulgate consumer product safety standards for durable infant or toddler products. These standards are to be “substantially the same as” applicable voluntary standards or more stringent than the voluntary standard, if the Commission determines that more stringent requirements would further reduce the risk of injury associated with the product. The Commission is proposing a safety standard for infant bouncer seats (“bouncer seats”) in response to the direction of section 104(b) of the CPSIA. In addition, the Commission is proposing an amendment to 16 CFR part 1112 to include 16 CFR part 1229 in the list of notice of requirements (“NORs”) issued by the Commission.

DATES:

Submit comments by January 4, 2016.

ADDRESSES:

Comments related to the Paperwork Reduction Act aspects of the marking, labeling, and instructional literature requirements of the proposed mandatory standard for bouncer seats should be directed to the Office of Information and Regulatory Affairs, the Office of Management and Budget, Attn: CPSC Desk Officer, FAX: 202-395-6974, or emailed to oira_submission@omb.eop.gov.

Other comments, identified by Docket No. CPSC-2015-0028, may be submitted electronically or in writing:

Electronic Submissions: Submit electronic comments to the Federal eRulemaking Portal at: http://www.regulations.gov. Follow the instructions for submitting comments. The Commission does not accept comments submitted by electronic mail (email), except through www.regulations.gov. The Commission encourages you to submit electronic comments by using the Federal eRulemaking Portal, as described above.

Written Submissions: Submit written submissions by mail/hand delivery/courier to: Office of the Secretary, Consumer Product Safety Commission, Room 820, 4330 East West Highway, Bethesda, MD 20814; telephone (301) 504-7923.

Instructions: All submissions received must include the agency name and docket number for this proposed rulemaking. All comments received may be posted without change, including any personal identifiers, contact information, or other personal information provided, to: http://www.regulations.gov. Do not submit confidential business information, trade secret information, or other sensitive or protected information that you do not want to be available to the public. If furnished at all, such information should be submitted in writing.

Docket: For access to the docket to read background documents or comments received, go to: http://www.regulations.gov,, and insert the docket number, CPSC-2015-0028, into the “Search” box, and follow the prompts.

Start Further InfoFOR FURTHER INFORMATION CONTACT:

Suad Wanna-Nakamura, Ph.D., Project Manager, Directorate for Health Sciences, U.S. Consumer Product Safety Commission, 5 Research Place, Rockville, MD 20850; telephone: 301-987-2550; email: snakamura@cpsc.gov.

End Further Info End Preamble Start Supplemental InformationSUPPLEMENTARY INFORMATION:

I. Background and Statutory Authority

The CPSIA was enacted on August 14, 2008. Section 104(b) of the CPSIA, part of the Danny Keysar Child Product Start Printed Page 63169Safety Notification Act, requires the Commission to: (1) Examine and assess the effectiveness of voluntary consumer product safety standards for durable infant or toddler products, in consultation with representatives of consumer groups, juvenile product manufacturers, and independent child product engineers and experts; and (2) promulgate consumer product safety standards for durable infant and toddler products. Standards issued under section 104 are to be “substantially the same as” the applicable voluntary standards or more stringent than the voluntary standard, if the Commission determines that more stringent requirements would further reduce the risk of injury associated with the product.

The term “durable infant or toddler product” is defined in section 104(f)(1) of the CPSIA as “a durable product intended for use, or that may be reasonably expected to be used, by children under the age of 5 years,” and the statute specifies twelve categories of products that are included in the definition, including walkers, carriers and various types of children's chairs. In issuing regulations governing product registration under section 104, the Commission determined that an “infant bouncer” falls within the definition of a “durable infant or toddler product.” 74 FR 68668 (Dec. 29, 2009); 16 CFR 1130.2(a)(15).

Pursuant to section 104(b)(1)(A) of the CPSIA, the Commission consulted with manufacturers, retailers, trade organizations, laboratories, consumer advocacy groups, consultants, and members of the public in the development of this notice of proposed rulemaking (“NPR”), largely through the ASTM process. The NPR is based on the most recent voluntary standard developed by ASTM International (formerly the American Society for Testing and Materials), ASTM F2167-15, Standard Consumer Safety Specification for Infant Bouncer Seats (“ASTM F2167-15”), with specific modifications to improve and strengthen the requirements for on-product warnings and instructional materials provided with bouncer seats.

The testing and certification requirements of section 14(a) of the Consumer Product Safety Act (“CPSA”) apply to the standards promulgated under section 104 of the CPSIA. Section 14(a)(3) of the CPSA requires the Commission to publish an NOR for the accreditation of third party conformity assessment bodies (“test laboratories”) to assess conformity with a children's product safety rule to which a children's product is subject. The proposed rule for bouncer seats, if issued as a final rule, would be a children's product safety rule that requires the issuance of an NOR. To meet the requirement that the Commission issue an NOR for the bouncer seat standard, this NPR also proposes to amend 16 CFR part 1112 to include 16 CFR part 1229, the CFR section where the bouncer seat standard will be codified, if the standard becomes final.

II. Product Description

A. Definition of “Bouncer Seats”

The scope section of ASTM F2167-15 defines an “infant bouncer seat” as: “a freestanding product intended to support an occupant in a reclined position to facilitate bouncing by the occupant, with the aid of a caregiver or by other means.” ASTM F2167-15 states that infant bouncer seats are intended for “infants who have not developed the ability to sit up unassisted (approximately 0 to 6 months of age).”

Bouncer seats vary widely in style and complexity, but typically, bouncer seats consist of a cloth cover stretched over a wire or tubular frame. Wire frame bouncers have two designs. The forward bend design is constructed with the seating area supported from the front side of the product. The second wire frame design is a rear bend design. In the rear bend design, the seat is supported from the rear side of the product. Other bouncer designs are also currently available, including, but not limited to, products with individual wire legs, solid bases, and spring designs. These infant bouncer designs use different methods to support the seat and are intended for “bouncing,” as defined in ASTM F2167.

All bouncer seats support the child in an inclined position, and some brands have adjustable seat backs. Various bouncer seat models include a “soothing unit” that vibrates or bounces the chair, and may play music or other sounds. Most bouncer seats also feature an accessory bar with attached toys that are, or at some point will be, within the child's reach. Most of the bouncer seat models examined by Commission staff provide a 3-point restraint system consisting of wide cloth crotch restraints, and short adjustable waist straps with plastic buckles. Only two models of bouncer seats reviewed by CPSC employed upper body restraints. Many bouncer seat brands also include an “infant insert,” intended for use to support smaller babies. See Tabs C and D, Staff Briefing Package: Infant Bouncer Seats Notice of Proposed Rulemaking, dated September 30, 2015 (“Staff NPR Briefing Package”), available at: http://www.cpsc.gov/Global/Newsroom/FOIA/CommissionBriefingPackages/2015/ProposedRuleSafetyStandardforInfantBouncerSeatSeptember302.pdf.

B. Market Description

Although additional suppliers may exist, CPSC staff identified 22 firms supplying infant bouncer seats to the U.S. market. The 22 identified firms primarily specialize in the manufacture and/or distribution of children's products, including durable nursery products. The majority of the 22 known firms are domestic (including 8 manufacturers and 10 importers). The remaining four firms are foreign manufacturers.[1] In 2013, the CPSC conducted a Durable Nursery Product Exposure Survey (“DNPES”) of U.S. households with children under age 6. Data from the DNPES indicate that an estimated 6.75 million infant bouncers are in U.S. households (with 95% probability that the actual value is between 5.78 million and 7.72 million). Data collected also indicate that about 31 percent of the infant bouncers in U.S. households are currently in use (an estimated 2.09 million infant bouncers, with 95 percent probability that the actual value is between about 1.5 million and 2.68 million). Tab F, Staff NPR Briefing Package.

III. Incident Data

CPSC's Directorate for Epidemiology, Division of Hazard Analysis is aware of 277 reported incidents involving bouncer seats, including 11 fatalities and 51 injuries, occurring between January 1, 2006 and February 2, 2015. The incidents are based on reports involving victims 12 months and younger in the Injury or Potential Injury Incident (“IPII”), In-Depth Investigation (“INDP”), and Death Certificates (“DTHS”) databases (collectively referred to as Consumer Product Safety Risk Management System data, or “CPSRMS” data). Additionally, CPSC staff found 672 bouncer-related incidents, including two fatalities, reported in the National Electronic Injury Surveillance System (“NEISS”) records retrieved for bouncer incidents from January 1, 2006 to December 31, 2013, involving children 12 months old and younger. A detailed review of the incident data and analysis associated with bouncer seats can be found in Tabs A, B, and D of the Staff NPR Briefing Package.Start Printed Page 63170

A. Fatalities

For the reporting periods described in the preceding paragraph, CPSC staff found 11 reported fatalities in the CPSRMS data, and two reported fatalities in the NEISS data. A brief description of each incident follows:

- 120427HCC1640: A 6-month-old died of blunt force trauma to the head when the infant's father lifted him in the bouncer seat. The bouncer collapsed and the child fell out of the back onto carpeted floor. He suffered a linear skull fracture and died the following day.

- 121001HCC2002: A 3-month-old was fed and left to sleep in her bouncer seat. The child's father reported that he found her face down, unrestrained, in the seat. The seat was on the floor, and the child's mother and 2-year-old sister had been asleep on a couch nearby.[2] Cause of death was positional asphyxia.

- 070214CCC1300: A 2-month-old who suffered from reflux and a respiratory infection was placed, unrestrained, to sleep in a bouncer that was lined with a blanket; the bouncer was on the floor next to the couch where his mother slept for the night. The child turned over in the seat, and was found unresponsive, face down against seat back. Cause of death was positional asphyxia.

- 110726CAA3941: A 3-month-old was placed on an adult bed in an infant bouncer seat, unrestrained, for a nap. The mother reported that the child had fallen out of the seat and she found her face down on the bed. The child was diagnosed with an irreversible anoxic brain injury and died 19 days later.

- 726037034: A 3-month-old was left in a “bouncey (sic) seat on an adult bed.” Cause of death was probable asphyxia due to suffocation. No further information is available.

- 1051041332: A 4-month-old “suffocated when face down in soft bedding on bouncey (sic) seat at home.” No further information is available.

- 101012HCC3049: A 6-month-old (born several weeks premature) was placed in a bouncer on the floor (in front of a television) as he was falling asleep while his mother showered. She placed a pillow under the rear legs of the bouncer to raise it. She found the child unresponsive, turned with his face against the side of the bouncer, one leg out of the restraints. Cause of death was positional asphyxia.

- 080917HBB3900: A 2-month-old in a bouncer was placed in a crib to sleep. She was found suspended, partially upside down, over the side of the bouncer with one leg entwined in the restraints. A depression in the mattress suggests that the child's face was against it. Cause of death was mechanical asphyxia.

- X1490229A: A 4-month-old was swaddled and placed for a nap, unrestrained, in a bouncer, which was then placed on the floor; the child reportedly just started to roll over, but had not done so completely on her own. Her parents found her unresponsive “with her face against the back of the infant seat and half way off the chair from the waist level down . . .”; she could not be resuscitated. Cause of death was positional asphyxia.

- 140102HWE0001: A 6-month-old was sleeping, strapped into a bouncer and when she awoke, was moved in the bouncer to a bedroom and left briefly with two toddlers, and possibly a pet dog. When the caregiver returned, she found the chair overturned on the floor with the victim's neck lying over the chair's [toy bar]. The report is inconsistent regarding whether the bouncer was placed initially on the bed or on the floor. HS staff considers the injuries described in the ME's report to be consistent with a fall rather than a tip-over at floor level. The child died five days later. Cause of death was positional asphyxia.

- 140422CAA1573: A 3-month-old was placed to sleep for the evening, unrestrained, in a bouncer on the floor in a room with several other children. Her mother found her five hours later face down in front of the bouncer on the floor and not breathing.

- NEISS: 120328281: The parents of a 5-month-old found him unresponsive, flipped over in the bouncer seat with his leg still through one leg hole. The cause listed was cardiac arrest.[3]

- NEISS: 130645295: A 2-month-old child had been asleep in a “bouncy”; his father awoke to find the child unresponsive on the floor. The cause of death was cardiac arrest.[4]

Most of the infants' deaths involved the presence of excess bedding in or under the bouncer; placement of the bouncer on a soft surface such as an adult bed; placement of the bouncer in a crib; and carrying or placing the bouncer at an elevated height. Most of the bouncer seat deaths also involved the infant being placed in the bouncer to sleep unrestrained, which allowed the infant unsupervised time and movement within the hazardous environment which contributed to the death. Tab B, Staff NPR Briefing Package. In nine cases, the child was reported as napping or sleeping and without restraints in five of the nine incidents. In two cases, the child was partially out of the restraints when found; in the case when the bouncer was inside the crib, the child was partially suspended upside down over the side of the bouncer with one leg in the restraints. Moreover, in at least four cases, the child's emerging ability to turn over, resulted in the child's face resting against the conforming surface of the seat back, and this appears to have been a significant factor in causing the child's death. Tab D, Staff NPR Briefing Package.

B. Non-Fatalities

Of the 277 CPSRMS bouncer-related incidents involving children 12 months old and younger, 266 incidents were nonfatal. Fifty-one (51) of these nonfatal incidents reported injuries. Four of the 51 reported injuries involved serious head injuries related to falls from a bouncer placed on an elevated surface. Other reported injuries included skull fractures, leg fractures, head contusions, eye bruises, facial bruises and scratches, a split lip and torn upper frenulum, a finger bruise, leg cuts, leg bruises, heel lacerations, and a blood blister. Because reporting is ongoing, the number of injuries and fatalities associated with bouncer seats are subject to change. See Tab A, Staff NPR Briefing Package.

Incidents involving the infant occupant falling from the bouncer are of most concern to CPSC because falls have the greatest potential for a serious injury. According to Health Sciences staff's analysis, 77 of the 266 nonfatal incidents involved the infant occupant falling from the bouncer. In five of these incidents, the infant occupant fell from a bouncer placed at an elevated height, such as on a kitchen countertop or dining table, or the bouncer was being carried by the caregiver; in four (80%) of these elevated-height incidents, the infant fell from the bouncer and sustained a severe head injury. Severe head injuries, such as concussions and fractured skulls, could cause extensive brain damage and affect the infant's motor development, emotional development, speech, ability to think and learn, and overall quality of life, long after the incident has occurred. The majority of the remaining 189 nonfatal incidents that did not involve a fall Start Printed Page 63171resulted in no injuries or minor injuries. Only one incident resulted in a moderate injury; in that incident a 3-month-old infant shifted in the bouncer and sustained a fractured leg. See Tab B, Staff NPR Briefing Package.

C. Hazard Pattern Identification for CPSRMS Incidents

To identify hazard patterns associated with infant bouncer seats, CPSC staff considered all 277 reported incidents in CPSRMS involving product-related issues. Tab A, Staff NPR Briefing Package. Product-related issues associated with these incidents include:

Product Design—Seventy-five (75) incident reports describe issues related to bouncer product design. Design issues described in these incident reports consist of sharp plastic rods, uncushioned side metal bars, overhead attachments not clipping properly, sharp pieces of fabric, lack of padding in the footing area, bouncer frames that easily entrap arms/legs/fingers, easily movable feet cushion flaps, sharp plastic grooves from a musical component, sagging seat belts, and lopsided or low-riding bouncer frames. Sixteen of the 75 incidents resulted in injuries, all of which were minor.

Structural Integrity—Seventy (70) incident reports describe issues related to the structural integrity of bouncer components, such as bouncer seats collapsing when picked up, collapsing during use, and releasing fabric from the plastic frame, plus various other structural issues involving broken sides, recline adjustment pieces, wire bases, front tube retainers, and rubber feet. Twelve of the 70 incidents resulted in minor injuries.

Toy Bar-Related—Thirty-six (36) incident reports involve problems with the toy bar or toys attached to the toy bar. These reports describe the following types of issues: Toy bars that fail to snap into place, toy bars breaking after being used as a handle, toys breaking off the bar, toys on the bar swinging back to hit the victim, toys scratching and pinching fingers or toes, and children getting hands or feet caught on the toy attachments. Ten of the 36 incidents resulted in minor injuries.

Stability—Stability issues comprise thirty-three (33) tip-over incidents involving a bouncer seat placed on the floor. While 26 bouncer tip-over incidents resulted in no reported injuries, seven incident reports include injuries such as a split lip, head contusions, and facial bruises.

Chemical/Electric Hazards—Thirty (30) incident reports describe issues related to chemical or electrical hazards, including two reported injuries (a thigh welt and a rash). One incident involved a bouncer seat emanating a toxic smell; another incident involved a victim who developed a rash after directly touching the bouncer; and 28 incidents involved batteries or the vibration motors. Twenty-four of the battery/motor incidents included reports of leaking, cracking, or exploding batteries. Four of the battery/motor incident reports specifically described motor-related issues, which include overheating motors, motors making strange noises, and motors catching on fire, resulting in burning plastic and structural burn marks.

Restraints—Twenty (20) incidents, including two reported minor injuries, involve issues with bouncer restraints, including falling out of bouncer seats despite being strapped in, tearing/fraying straps, non-latching seat belts, and breaking seat buckles.

Hazardous Placement—Eleven (11) incidents involved a hazardous placement of the bouncer where victims in bouncer seats fell from elevated surfaces, fell face down onto soft bedding, or suffocated while attempting to slip out of a bouncer seat placed on an unstable surface. One incident included a reported skull fracture injury; another incident involved a fatality resulting from blunt force head trauma; and nine incidents involved fatalities due to asphyxia.

Unknown—Two (2) incidents involved an unknown hazard, including one that involved a reported injury, and one that resulted in a death from positional asphyxia.

D. NEISS Data Analysis

CPSC staff retrieved 672 NEISS records (estimated total of 17,200 injuries) describing infant bouncer seat incidents between January 1, 2006 and December 31, 2013. See Tab A, Staff NPR Briefing Package. Injury estimates are derived from NEISS data, where sampling weights are used to project the number of cases reported by NEISS hospitals to national estimates. A statistically significant upward trend exists in the estimated emergency department-treated injuries involving bouncer seats for victims under 1-year-old from 2006 to 2013.

An estimated 15,500 patients were treated and released for bouncer injuries, and an estimated 1,300 patients were treated and admitted, treated and transferred to another hospital, or held for observation. An estimated 15,100 (92%) bouncer injuries involved the head and face, while 1,300 estimated injuries involved an unknown area, or the rest of the body (appendages, torso, internal). Two cases involved a victim who died from cardiac arrest. One victim died after flipping over in an infant bouncer seat with his leg still through one leg opening, and the other victim was found on the floor unresponsive after being asleep in the bouncer. These two fatalities are in addition to the 11 fatalities reported in CPSRMS.

Of the 672 NEISS records describing bouncer injuries, 287 incidents took place on the floor or an unknown location. The remaining 385 incidents, or an estimated 9,200 injuries, involved hazardous placements: 342 of these incidents, or an estimated 8,100 injuries, resulted from falls. Hazardous placements included counters, tables, and other elevated surfaces (e.g., beds, carried or lifted positions, chairs, couches, dressers, stairs, and appliances). An estimated 6,800 injuries, or 74 percent of all estimated bouncer injuries associated with a hazardous placement, involved the bouncer being placed on a counter or table. Health Sciences staff analysis determined that 50 of these hazardous placement incidents resulted in a severe head injury, such as a concussion or fractured skull. Twelve severe head injuries were the result of the caregiver carrying the infant in the bouncer. See Tab B, Staff's NPR Briefing Package. CPSC staff noted two other factors in the fall-related NEISS data. In 54 of the reports, the incident occurred when someone was carrying or picking up the child in the infant bouncer. In 33 of the cases, the child was reported to be unrestrained at the time of the incident; the number of cases of children falling while unrestrained is likely to be underreported.

Eighty-one percent of the incidents resulted in injuries (n=532; estimate=13,900). CPSC staff reviewed the NEISS cases and determined the severity of the reported injuries. Based on that analysis, 11 percent of the injuries were severe, such as skull fractures and intracranial hemorrhages; and 41 percent were moderate, such as less serious head injuries and fractures involving other body parts. CPSC staff concluded that infants were more likely to sustain a severe head injury when they fell from elevated heights, and that the potential for severe head injury increases if the child is being carried in the bouncer, and/or if they are unrestrained in the bouncer.

E. Product Recalls

Since January 1, 2006, Compliance staff conducted two bouncer seat recalls involving two different firms. The first recall, in April 2007, involved 1,400 Start Printed Page 63172units of Oeuf, LLC, infant bouncer seats.[5] The bouncer seat was recalled after six reports of tubular steel frame breakage. The second recall of bouncer seats, in July of 2009, involved 6,500 units of BabySwede LLC BabyBjörn® Babysitter Balance and Babysitter Balance Air bouncer seats.[6] Bouncer seats were recalled because small, sharp metal objects found in the padded area of the bouncer chair could protrude through the fabric, posing a laceration hazard to children. No injuries were associated with either product at the time of the recall. See Tab E, Staff NPR Briefing Package.

IV. International Standards for Bouncer Seats

CPSC staff found no other standard for infant bouncer seats. See Tab C, Staff NPR Briefing Package. However, CPSC staff identified two closely related international standards, BS EN 14036:2003, Child Use and Care Articles—Baby Bouncers—Safety requirements (“BS EN 14036”) and BS EN 12790:2002, Test Methods and Child Care Articles—Reclined cradles (“BS EN 12790”), which pertain to products with some characteristics similar to infant bouncer seats. The scope of BS EN 14036 does not include bouncers intended for inclined seating; rather, the standard involves products designed to suspend a child, from above, in an essentially vertical, semi-seated position. These products, sold as baby jumpers in the United States, enable the child's toes/balls of the feet to have contact with the floor to activate and maintain the bouncing action. General requirements in BS EN 14036 are similar to ASTM F2167, but are less stringent. Remaining requirements in BS EN 14036 are not applicable to infant bouncer seats.

BS EN 12790 specifies safety requirements and the corresponding test methods for fixed or folding reclined cradles intended for children up to 6 months and/or up to a weight of 9 kg. Unlike infant bouncer seats, BS EN 12790 is intended to cover non-bouncing products designed to be a safe sleeping environment. BS EN 12790 contains the same general requirements as BS EN 14036. Additional testing in BS EN 12790 includes stability, static strength, dynamic strength, slip resistance, unintentional folding, and restraints. ASTM F2167 contains more stringent stability, static strength, and dynamic testing than BS EN 12790. Slip-resistance tests are substantially similar in both standards. BS EN 12790 contains an unintentional folding test that is not applicable to infant bouncer seats. Finally, although ASTM F2167 does not have a restraint slip test, the restraint strength test requires an additional pull test at 45lb (200 N) to the normal use direction. Accordingly, overall, ASTM F2167-15 is more stringent in most areas than BS EN 12790 and addresses the hazard patterns identified in CPSC's incident data.

V. Voluntary Standard—ASTM F2167

A. History of ASTM F2167

A voluntary standard for infant bouncer seats was first approved in December 2001 and published in January 2002, as ASTM F2167-01, Standard Consumer Safety Specification for Infant Bouncer Seats. Since then, ASTM has revised the standard nine times. Tab C of the Staff NPR Briefing Package includes a description of each revision. The current version, ASTM F2167-15, was approved on May 1, 2015, and published in June 2015. ASTM F2167-15 includes modified and new performance and labeling requirements developed by CPSC staff, in conjunction with stakeholders on the ASTM subcommittee task group, to address the hazards associated with bouncer seats. A description of the current voluntary standard for bouncer seats follows.

B. Description of the Current Voluntary Standard—ASTM F2167-15

ASTM F2167-15 includes the following key provisions: Scope, terminology, general requirements, performance requirements, test methods, marking and labeling, and instructional literature.

Scope. Section 1 of ASTM F2167-15 states the scope of the standard, detailing what constitutes an “infant bouncer seat.” As stated in section II.A of this preamble, the Scope section defines an “infant bouncer seat” as “a freestanding product intended to support an occupant in a reclined position to facilitate bouncing by the occupant, with the aid of a caregiver or by other means.” ASTM F2167-15 states that infant bouncer seats are intended for “infants who have not developed the ability to sit up unassisted (approximately 0 to 6 months of age).”

Terminology. Section 3 of ASTM F2167-15 provides definitions of terms specific to this standard. For example, section 3.1.1 of the ASTM standard defines “conspicuous” to mean a “label that is visible, when the infant bouncer seat is in a manufacturer's recommended use position, to a person sitting near the infant bouncer seat at any one position around the infant bouncer seat but is not necessarily visible from all positions.”

General Requirements. Section 5 of ASTM F2167-15 addresses numerous hazards with several general requirements, most of which are also found in the other ASTM juvenile product standards. Several requirements reference an existing CPSC standard. The following general requirements apply to bouncer seats. Where the ASTM standard relies on a CPSC mandatory standard, the mandatory standard is cited in parentheses next to the requirement:

- Hazardous sharp points and edges (16 CFR 1500.48 and 1500.49);

- Small parts (16 CFR 1501);

- Lead in paint (16 CFR 1303);

- Banned articles (16 CFR 1500.18(a)(6) and 1500.86(a)(4));

- Wood parts;

- Latching and locking mechanisms;

- Scissoring, shearing, and pinching;

- Openings;

- Exposed coil springs;

- Protective components;

- Permanency of labels and warnings; and

- Toys (ASTM F963).

Performance Requirements and Test Methods. Sections 6 and 7 of ASTM F2167-15 contain performance requirements specific to bouncer seats, as well as test methods that must be used to assess conformity with such requirements. Below is a discussion of each performance requirement and the related test method.

- Restraints. ASTM F2167-15 requires that restraints be provided with a bouncer seat that are capable of securing a child when the bouncer is placed in any use position recommended by the manufacturer. ASTM F 2167-15 requires both a waist and a crotch restraint, and the restraint must be designed in such a way that the crotch restraint must be used when the waist restraint is in use. The standard specifies that the restraint's anchorages shall not separate from the attachment points to the bouncer when tested. Testing to this requirement is performed by securing the bouncer seat and applying a 45lb (200N) force for a period of 10 seconds to a single attachment point of the restraint in the normal use direction. Although no provisions in the performance requirements address the actual use of the restraint, ASTM F2167-15 contains a warning label requirement regarding proper use of the restraint.Start Printed Page 63173

- Stability. ASTM F2167-15 includes a test for bouncer stability in each direction, forward, sideward, and rearward. In the forward stability test, an infant CAMI dummy is placed in the infant bouncer and the restraints are adjusted to fit in accordance with the manufacturer's instructions. The dummy is then removed and the stability test fixture is placed in the seat. A vertical static force of 21lb (93N) or three times the manufacturer's recommended weight, whichever is greater, is applied for 60 seconds to the fixture at a distance of 6in (152.4mm) in front of the crotch post. To pass the test, the bouncer must not tip over or the front edge must not touch the test surface.

Repeatable stability testing in the sideward and rearward directions is more difficult to accomplish based on a bouncer's potential shifts in the center of gravity. Because of these potential shifts, sideward and rearward testing for bouncers is done differently than in the forward direction. The current sideward and rearward stability tests are performed with the infant CAMI dummy placed in the seat and the bouncer placed on a 20-degree incline in the most unstable orientation other than forward. To pass the test, the bouncer must not tip over in this position.

- Slip Resistance. The slip resistance test is designed to keep bouncers from traveling across a surface while being used by a child. Bouncers placed on smooth, hard surfaces, such as a kitchen counter, are less likely to creep along the surface while a child is in the seat, if the product is designed to meet the slip resistance requirement. The slip resistance requirement in ASTM F2167-15 includes both static and dynamic components. The static slip resistance test is performed on a smooth laminate surface with a matte finish and a 10-degree incline. A 7.5lb (3.4kg) CAMI dummy is placed in the bouncer with the front of the bouncer facing down the incline. The bouncer must not move down the incline more than 1/8 in. (3mm) in 1 minute. The test is repeated with the bouncer seat oriented with the left, right, and rear sides pointed down the incline.

In the dynamic slip resistance test, a test fixture is placed in the bouncer seat with a 7.5lb (93.4kg) weight, and the bouncer is placed on the 10-degree inclined surface. Additionally, if the bouncer has a feature, such as a vibration unit, the unit is to be turned on during the test. An additional 2.5lb (1.13kg) weight is dropped onto the test fixture from a height of 6 in. (152.4mm) a total of 10 times. To pass, the bouncer seat is not allowed to move more than 1/2in (13mm) during the test. This test is repeated with the bouncer in the remaining sideways and rear orientations.

- Structural Integrity and Disassembly/Collapse. ASTM F2167-15 requires that bouncer seats pass a series of three tests to evaluate structural integrity: (1) A static load test; (2) a dynamic load test; and (3) a disassembly/collapse test.

To pass the first two tests, at the conclusion of the tests, the bouncer seat shall have no failure of seams, breakage of materials, or changes of adjustments that could cause the product not to fully support the child or that creates a hazardous condition outlined in the general requirements of the standard. The static load test requires that a 6″ × 6″ × 3/4″ (152.4 × 152.4 × 1.91mm) wood block be placed in the bouncer seat and loaded with the greater of 60lb (27.3kg), or 3 times the manufacturer's recommended maximum weight, whichever is greater. The test is intended to ensure that the bouncer design is sufficient to hold the weight of any child that is likely to use the product.

The dynamic load test requires that a 6″ (152.4mm) weld cap be dropped from a distance of 1″ (25mm) with the convex surface face down onto the bouncer seat. Extra weight is added to the weld cap to provide a total weight of 33lb (15kg). The drop for the dynamic load test is repeated a total of 100 times. This test simulates the child being placed in the seat and removed, as well as the forces applied to the bouncer while the child is in the seat. This test provides a reasonable factor of safety to ensure that the bouncer seat does not fail when used in accordance with the manufacturer's recommendations.

The disassembly/collapse test simulates lifting the bouncer by the ends with a child seated in the product to see whether the bouncer collapses or folds up into a position that might result in injury. To conduct the test, a newborn CAMI dummy is placed in the bouncer seat and a 15lb (67N) force is applied to the bouncer at the location most likely to cause disassembly. In situations where multiple locations are present that could result in disassembly, the test is repeated for each location. If a hazardous condition results from the test, the bouncer fails the requirement. A hazardous condition is anything that would result in the bouncer not meeting the general requirements, or any visual indications of disassembly or collapse of the bouncer.

- Drop Test. The drop test is intended to evaluate the durability of bouncer seats in instances of misuse, and to assess compliance with the general safety requirements, such as small parts, sharp points, and sharp edges. The drop test applies dynamic forces to the bouncer in directions not associated with normal use by a child. The bouncer must be dropped from a height of 36″ (914.4mm), once in each of six different planes (top, bottom, front, rear, left side, and right side). If the bouncer is of a folding design, the six drops must be done in both the folded and unfolded configurations (for a total of 12 drops). At the end of the test, the bouncer must meet the general requirements outlined in Section 5.0 of the standard.

- Toy Bar Attachment Integrity. ASTM F2167-15 includes general performance requirements to test toy bars on bouncer seats. A static test is performed with a 6″x6″x3/4″ (152.4x152.4x1.91mm) wood block placed in the bouncer seat and loaded with the greater of 40lb (18.2kg) or two times the manufacturer's recommended maximum weight. The bouncer is then gradually lifted. In the dynamic test, an infant CAMI is placed in the seat and a cable is attached to the center grasping point of the handle. The bouncer is raised and allowed to drop 2″ (5.1cm). The toy bar must completely release from the bouncer or move less than 2″ (5.1cm) from the resting position if the bar has a single attachment point. Additionally, individual toys included with the bouncer are required to meet the general requirements in the standard.

- Battery Compartments. ASTM recently added battery and containment requirements to F2167. The new requirements include permanently marking the correct battery polarity adjacent to the battery compartment, providing a means to contain the electrolytic material in the event of battery leakage, protection against the possibility of charging non-rechargeable batteries, and defining a maximum surface temperature for any accessible component. The battery polarity requirement requires a visual inspection of the battery compartment. Surface temperature and charging protection are accomplished through the performance of an operational test. The bouncer is operated using new batteries of the type recommended by the manufacturer. Testing is performed by operating the bouncer at the highest setting for 60 minutes. Upon conclusion, no battery leakage, explosion, or fire can occur, and no accessible component shall exceed 160 °F degrees (71°C). The performance requirement includes a provision for testing using a/c power; but staff is unaware of bouncers Start Printed Page 63174currently on the market that are a/c powered.

Marking and Labeling. Section 8 of ASTM F2167-15 requires products to be marked or labeled with manufacturing information and relevant product warnings.

- Manufacturing Information. Section 8.1 requires that each product and its retail packaging be marked or labeled, clearly, legibly, and permanently, to include the name and address of the manufacturer, distributor, or seller, and a code or other means to identify the date of manufacture. Section 8.2 states that a manufacturer should change the model number when the product undergoes a significant structural or design change that affects conformance to the standard.

- Product Warnings. CPSC staff and the ASTM task group and subcommittee worked to improve the warning label requirements for bouncer seats in section 8.3 of ASTM F2167 to address the hazard of falls from elevated surfaces. ASTM F2167-15 includes several changes to the warnings requirements intended to address this hazard, as well as suffocation. Bouncer seats must be labeled with two groups of warning statements, a fall hazard warning and a suffocation warning. ASTM F2167-15 includes new content on color in the warning labels, placement of the fall hazard warning on the front of the product, and changes to the suggested warning language for both falls and suffocation. As set forth in more detail in section VI of the preamble, CPSC is proposing to include additional changes to the warning label requirements to address the deaths and injuries associated with infants falling from bouncer seats, and associated with infants falling while remaining in the seat, that occur when caregivers place bouncer seats on an elevated surface.

Instructional Literature. Section 9 of ASTM F2167-15 requires that instructions be provided with bouncer seats and be easy to read and understand. Additionally, the section contains requirements relating to instructional literature contents, including warnings.

VI. Assessment of the Voluntary Standard ASTM F2167-15

CPSC staff examined the relationship between the performance requirements in ASTM F2167-15 and each of the hazard patterns identified in section III.C of this preamble. Tab C, Staff NPR Briefing Package. Based on staff's assessment, CPSC finds that the current voluntary standard, ASTM F2167-15, adequately addresses the mechanical hazard patterns identified in the incident data associated with bouncer seats. However, CPSC finds that the warning label requirements in ASTM F2167-15 can be improved to address infant falls from bouncers placed on an elevated surface. At this time, such falls cannot be addressed by a performance requirement for bouncer seats. Addressing incidents when infants fall from bouncer seats, as well as incidents when infants fall while remaining in the seat, will require a change in caregiver behavior. Accordingly, CPSC is proposing to strengthen the requirements for the warning label to increase compliance by caregivers and reduce the risk of injury to infants. Tab D, Staff NPR Briefing Package.

The following section discusses how each of the product-related hazard patterns identified in section III.C of this preamble is addressed by the current voluntary standard, ASTM F2167-15. Where CPSC is proposing additional requirements, the rationale for these changes is also explained.

A. Product Design—CPSC staff evaluated the current requirements in ASTM F2167 and tested bouncer samples to the tests for product design. The performance requirements to test for hazards related to product design are the same as those used to test for structural integrity. Additionally, the drop test and the general requirements in Section 5.0 are used to address this hazard pattern. CPSC staff found that each type of failure identified in the incidents is addressed in the standard with performance requirements and associated tests. CPSC staff opined that many of the incidents may be the result of manufacturing, shipping, or consumer assembly-related issues. Accordingly, at this time, the Commission does not believe that adding or strengthening requirements is likely to reduce the occurrence of these incidents, and the current performance requirements are adequate to address this hazard pattern.

B. Structural Integrity—As reviewed in section V.B of this preamble, ASTM F2167-15 subjects infant bouncers to a series of three tests to evaluate structural integrity including: (1) A static load test; (2) a dynamic load test; and (3) a disassembly/collapse test. After reviewing the available incident information, CPSC staff concluded that it is likely that many of the incidents included in the structural integrity category are the result of product misassembly, and may not be the result of product design. CPSC staff opined that the three structural tests subject infant bouncers to the reasonable forces that could be applied during the normal life of the product and adequately test the structural strength of a bouncer. Based on staff's assessment, the Commission is not proposing to add more stringent performance requirements at this time.

C. Toy Bar-Related—Based on staff's assessment of the standard, the toy bar requirements in ASTM F 2167-15 are adequate to address the identified hazards. Staff evaluated many bouncers that included a bar designed with small toys attached that hang over the body of a child seated in the bouncer. Individual toys included with the bouncer are required to meet the general requirements in the standard, including ASTM F 963. Additionally, the toy bar is required to meet the toy bar integrity test requirement. The toy bar integrity requirement uses two different tests, a static integrity test and a dynamic integrity test, to address incidents in which the toy bars are used as handles. CPSC is unaware of any injuries involving toy bars releasing when being used as a handle that have occurred since 2012, when the toy bar integrity tests were added to ASTM F2167. Although many of the recent toy bar incident reports describe consumer complaints about the toy bar releasing or bending, CPSC does not consider these reports to be safety related, because the toy bars are specifically designed to perform in a manner that does not allow a consumer to use the toy bar as a handle, and no reported injuries resulted from these incidents.

D. Stability— ASTM F2167-15 adequately addresses stability-related incidents. CPSC staff worked with the ASTM subcommittee on bouncers to modify and enhance all the stability performance requirements. Beginning with ASTM F2167-14, the rear and side stability tests were strengthened by ASTM when the angle of incline was from 12 to 20 degrees. Additional changes in ASTM F2167-15 include a longer distance between the crotch post of the test fixture and the application of force for the forward stability test. Changes to the stability requirements will require the design of increasingly stable bouncer designs similar to ones currently available. CPSC believes that these additional requirements will reduce the likelihood of bouncer tip overs and associated injuries.

E. Chemical/Electrical Hazards—To address reported chemical and electrical incidents, ASTM recently added battery and containment requirements to the 2015 version of ASTM F2167. These additional requirements were developed with support from CPSC staff and based on the incidents reported to CPSC. New requirements include permanently marking the correct battery polarity Start Printed Page 63175adjacent to the battery compartment, providing a means to contain the electrolytic material in the event of battery leakage, protection against the possibility of charging non-rechargeable batteries, and defining a maximum surface temperature for any accessible component. Based on CPSC staff's assessment, CPSC believes that the new battery requirements adequately address reported electrical incidents by reducing the likelihood of overheating and battery leakage incidents.

F. Restraints—ASTM F2167-15 adequately addresses mechanical incidents involving restraints. ASTM F2167-15 requires that restraints be provided with a bouncer seat. Restraints must be capable of securing a child when the bouncer is placed in any use position recommended by the manufacturer. ASTM F 2167 requires both a waist and a crotch restraint, and the restraint must be designed in such a way that the crotch restraint must be used when the waist restraint is in use. Additionally, on-product warning information regarding use of restraints is required. See Tab D, Staff NPR Briefing Package. As described below in section VI.G.1, CPSC is proposing additional language for the product warning label to address incidents involving children who fell from bouncers when placed, unrestrained, to sleep.

G. Hazardous Placement—Hazardous placement of bouncer seats occurs when caregivers place bouncers in a hazardous environment, resulting in suffocation or head injuries. Factors that contribute most to these hazards include the presence of excess bedding in or under the bouncer; placement of the bouncer on a soft surface, such as an adult bed; placement of the bouncer in a crib; the infant being placed in the bouncer to sleep unrestrained, which allows the infant unsupervised time and movement within the hazardous environment; and carrying or placing the bouncer at an elevated height. ASTM F2167 addresses hazardous placement of bouncer seats with tests for stability and slip resistance, designed to keep bouncers from traveling across a surface while being used by a child. These performance requirements may help reduce the risk of injury in hazardous placement.

Although the standard includes performance testing for better stability and slip resistance, addressing hazardous placement incidents with performance requirements is difficult because the hazard scenario involves consumer behavior, a foreseeable misuse of the bouncer seat, which should be used only on the floor. Accordingly, CPSC is proposing modifications to the text, placement, and formatting of warnings requirements and instructional literature requirements of ASTM F2167-15 to help further reduce injuries related to this hazard pattern. A detailed description of staff's assessment, rationale, and citations to the relevant literature for the recommended changes appear in Tab D of the Staff's NPR Briefing Package.

1. Modifications to the Warning Label Content

The Commission proposes to add two components to the warning statements for bouncer seats that are absent in ASTM F2167-15: (1) The phrase “even if baby is sleeping” to the warning to use restraints; and (2) developmental guidance on when to stop using the product to help avoid suffocation and fall risks. In general, guidelines for warning statements agree that warnings should identify the hazards, the consequences, and the means to avoid them (e.g., Madden, 2006; Singer, Balliro, & Lerner, 2003, October). The content of the proposed modified warnings meets these requirements by calling attention to each of the behaviors that are related to the specific hazards identified, and advising caregivers how to avoid those hazards.

(a) Use of Restraints

“Always use restraints” is a part of the warnings and instructions in the current version of ASTM F2167, and has been so over many editions of the standard. Based on the incident data relating deaths to suffocation among unrestrained infants while they slept, and serious head injuries to unrestrained infants in falls from bouncer seats that are placed on elevated surfaces and falls from bouncer seats that are being carried, CPSC believes that the current requirement is inadequate to address the risk of injury to infants from falls out of bouncer seats, or the risk of suffocation among unrestrained infants who are sleeping.

The Commission's proposed warning language includes the statement, “Adjust to fit snugly, even if baby is sleeping.” ASTM F2167-15 lacks the phrase that addresses sleeping. CPSC staff reports that while working with ASTM, some ASTM members expressed the opinion that “Always use restraints” is adequate because it allows for no exceptions to the use of restraints, and contended that the staff's recommended language communicates that the product is intended for use as a place for the child to sleep, and may encourage such use. One member was concerned that including language regarding sleep may suggest that manufacturers should bring bouncers into compliance with requirements for products that are designed for sleep.

Although the Commission understands the marketing concerns of some manufacturers, the proposed rule addresses how caregivers use bouncer seats, the sleeping activity of infants that are intended to use the product, and the deaths and injuries reflected in the data when caregivers fail to use restraints. Accordingly, to address caregiver behavior, it is essential to include language that conveys the hazard associated with allowing a child to sleep in a bouncer seat while unrestrained. The Commission's concern is that young infants, such as those intended to use bouncer seats, spend more time asleep than awake.[7] Infants that spend more than brief periods in a bouncer seat will fall asleep on occasion (and caregivers will place infants to sleep for the night in bouncer seats under some circumstances), just as infants fall asleep in strollers, swings, and car-seat carriers. It may be counterintuitive, and therefore unlikely to occur to consumers, that products made for infants' use, especially those that have features intended to soothe and comfort them, would be unsafe places for infants to sleep. In fact, despite claims that bouncer seats are not intended for children to sleep in, CPSC staff found that some manufacturers' marketing suggests that bouncers are intended for sleep as well as play.

Caregivers may remove or loosen restraints while a child is sleeping in a bouncer seat. Removing or loosening product restraints while a child naps or sleeps is a known hazard pattern across infant products that use restraints. It is foreseeable that some caregivers will perceive the restraints as uncomfortable and unnecessary (Lerner, Huey, & Kotwal; 2001), particularly for younger users, who may be seen as not yet mobile enough to be at risk of falling out of the bouncer, and even less at risk of falling if the infant is asleep. CPSC's proposed warning statement addresses the fact that a child will sleep in the bouncer, and addresses caregivers' known inclination to loosen or remove the restraints by specifying that they should do the opposite to avoid the risk of injury or death from the child falling from the bouncer seat or turning in the seat.Start Printed Page 63176

(b) Developmental Guidance

The second modification to ASTM F2167-15 in CPSC's proposed warning content is in the developmental guidance given in the suffocation warning and in the product instructions. The warning in the current ASTM standard includes the developmental statement: “never use for a child able to sit up unassisted,” a milestone which, on average, a child will accomplish at about 6 months of age. Some packaging and instructions that CPSC staff reviewed also stated that the product is for use from birth until the child is able to sit up unassisted, and use a weight limit (25 lb) that reflects a 50th percentile 18-month-old. The Commission is concerned that this combination of guidance leads caregivers to use the product beyond the point that it is safe. Before infants can sit steadily by themselves, they lack upper body and torso control, but actively try to sit, turn, and reach for objects. Infants in bouncer seats are supported in an inclined position with their upper body unconstrained. The infant's actions may cause them to hang over the side or front, fall out or tip over the bouncer, or turn into the surface of the seat where the flexible, conforming design of the seat can compromise the external airways.

CPSC proposes that the bouncer seat warning label and product instructions advise caregivers to stop using the product when children start trying to sit up. On average, children reach this milestone at 4.8 months.[8] CPSC staff recommended this milestone based on the data indicating that most witnessed instances in which the child's activities reportedly preceded tip-overs or resulted in the child hanging out of the bouncer involved children 5 months of age or younger.

2. Modifications to Warning Label Placement

Language in ASTM F2167-15 requires the fall hazard warning to appear anywhere on the front surface of the product's seat back. To address hazards, warning labels must be conspicuous, formatted to help attract and maintain attention, and include appropriate instructional content. Accordingly, CPSC proposes that the fall hazard warning label be required to be on the front of the product near the infant's head to increase the likelihood that caregivers will notice it, and comply with its recommendations, at decision points affecting the child's safety. This location near the infant's head was adopted for warnings on hand-held infant carriers in 16 CFR part 1225, Safety Standard for Hand-Held Infant Carriers (“HHIC”; FR 78, No. 235; 73415, December 6, 2013) and the National Highway Transportation Administration's (“NHTSA”) car seat standard, 49 CFR 571.213 Federal Motor Vehicle Safety Standard (“FMVSS”) No, 213.

CPSC's research indicates that placement of the warning label near the child's face on the bouncer seat is essential in the effort to influence caregivers' behavior. Research indicates that the location of a warning label plays a vital role in its salience, a crucial factor in effectiveness (cf. topic reviews by Lesch, 2006; Silver & Braun, 1999). ASTM F2167-15 requires only that the label be visible on the front surface of the seat back with the Newborn CAMI manikin placed in the seat. The Commission is concerned that, because of its artificial and static nature, the test procedure in ASTM F2167-15 for visibility of the fall hazard warning label is unlikely to replicate visibility of the label under normal conditions of product use. In addition to allowing considerable variability in the conspicuity of the label location, a basic flaw in this method is the assumption that what is visible under static test conditions will be visible during routine use. A label below the shoulder level or along the torso down to the seat bight may be covered by parts of the child's body or clothing, and the area may be covered by a blanket, including an accessory cover that comes with at least one product.

Because a label must be seen to have an effect, visibility is a prerequisite to effectiveness. Visibility, in itself, however, is an insufficient requirement. Given the number, type, and severity of the incidents that prompted the revisions to the warnings, the appropriate criterion is that the label be likely to draw the caregiver's attention at any decision point that may affect safe use. As with the required labeling for hand-held infant carriers, the warning label should be near the child's face because that is where the caregiver's attention is most likely to be focused. This is the most conspicuous location on the product and offers the best opportunity to influence the caregiver's behavior.

During the ASTM process, when CPSC staff suggested locating the fall hazard warning next to the infants' head, ASTM subcommittee members expressed concerns that (1) common label materials present potential abrasion and cut hazards if adjacent to an infant's face; (2) the location is design-restrictive for smaller models because of the size of the label; and (3) due to space restrictions, the location is challenging for those firms that use labels in multiple languages.

Based on staff's review of bouncer seats and the identified issues, the Commission believes these issues can be resolved. As noted above, CPSC's proposed location for the fall hazard warning is the same as that recently adopted for warnings on infant car seats that are also hand-held carriers. NHTSA adopted this location for its air bag warning in these products in the late 1990's, based on its own research. CPSC staff examined car seats and found that both heat transfer and sewn-on labels, the latter of which was identified by industry as a concern, are used on car seats. CPSC's project manager for the hand-held carrier standard reported that neither injuries nor space requirements due to the need to produce labels in multiple languages were raised as concerns for hand-held carriers. Firms that produce infant car seat carriers have managed these issues successfully. CPSC staff contacted NHTSA staff responsible for routine data review, who confirmed that there have been no complaints of injury of any type resulting from car seat labels near a child's face. Finally, CPSC's proposed label is approximately 2.25 inches long and 2.0 inches wide. Review of hand-held infant carriers that are also infant car seats, which require a larger [9] label for both the CPSC mandated strangulation warning and the NHTSA-mandated air bag warning, suggests that there is at least as much space, and perhaps more, on many infant bouncer models, as on car seat carriers.

Although no voluntary or mandatory requirement exists for multiple languages on products sold in the U.S., given the relatively small size of the proposed warning label, multiple options appear available to firms for placement of the fall hazard warning in multiples languages. For example, the warning label could appear in a different language on either side of the child's head, as suggested by the Canadian representative to the task group; different labels could be made for different markets; or the label length could be extended to accommodate additional languages, as some firms have done with infant car seat labels.Start Printed Page 63177

3. Modifications to Warning Label Format

ASTM F2167-15 (1) allows the text and the background of the warning label, except for the area behind the word “WARNING,” to be any color as long as it is contrasting, and (2) provides no format guidance. Although example labels with CPSC's recommended format are presented in the voluntary standard, the standard includes the permissive statements that the figures “ . . . are presented as EXAMPLES ONLY . . . [emphasis in original]” and that the format and “wording content,” as well as the use of highlighting, “are at the discretion of the manufacturer.”

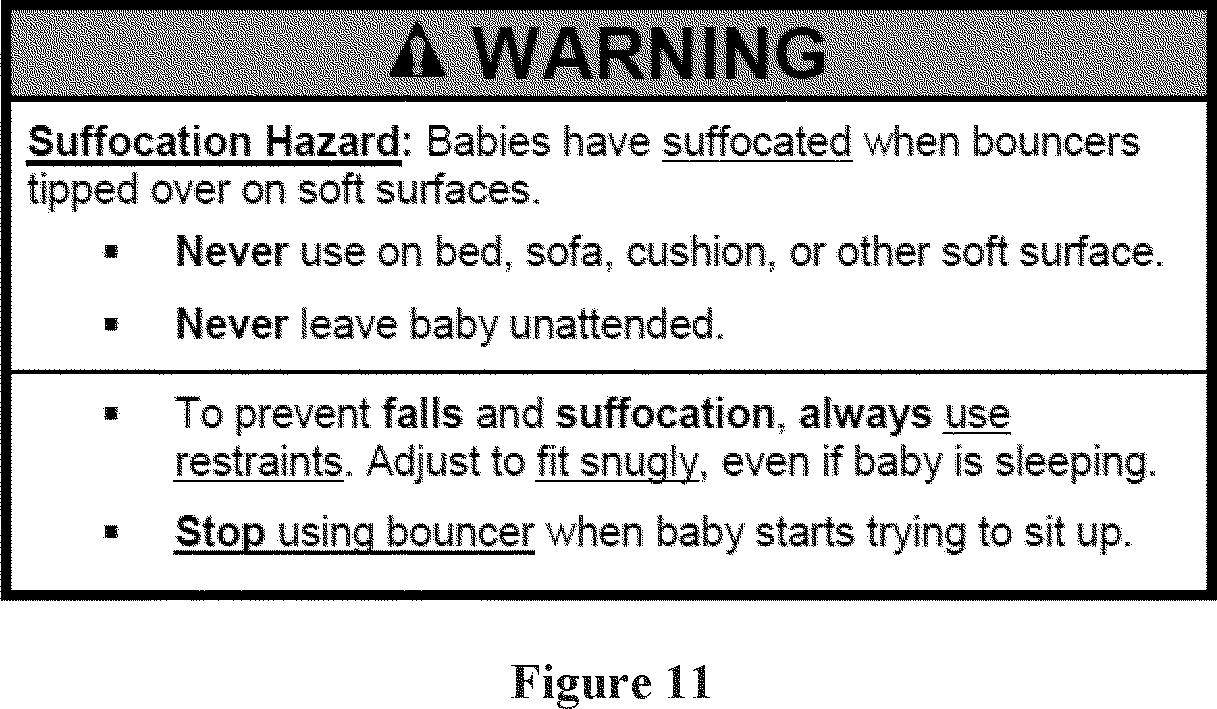

The Commission proposes that the formatting requirements for bouncer seats reflect the format shown in the label in Figure 1. Good formatting helps attract and maintain attention, and aids reading and comprehension. Information is processed more quickly and easily when it is organized by content into brief chunks. CPSC is concerned that the quoted statements make it likely that some firms will continue to use poor quality labels that present warning information in a cluttered paragraph style that is difficult to read, rather than a label that is conspicuous, easy to read, and easy to comprehend, as is the recommended warning label.

VII. Proposed CPSC Standard for Bouncer Seats

The Commission concludes that ASTM F2167-15 adequately addresses most of the hazards associated with bouncer seats, but proposes to modify the warning label requirements to increase effectiveness aimed at changing caregiver behavior to further reduce the risk of injury to infants from falls. Thus, the Commission proposes to incorporate by reference ASTM F2167-15 with the following modifications to the warning label requirements:

- Revise the content of the warnings, markings, and instructions to:

- Add text to the warnings that states to use the restraints “. . . even if baby is sleeping . . .”;

- change the text in the warnings to read, “stop using when baby starts trying to sit up”; and

- change the developmental guidance in the instructions, if stated, to read, “from birth (or “0”) until baby starts trying to sit up.”

- Require that the fall hazard label be located on the front surface of the bouncer adjacent to the area where the child's head would rest, and modify the current visibility test to reflect this requirement.

- Specify a standard format (including black text on a white background, table design, bullet points, and black border) for the warnings on the product and in the instructions.

VIII. Amendment to 16 CFR Part 1112 To Include NOR for Bouncer Seat Standard

The CPSA establishes certain requirements for product certification and testing. Products subject to a consumer product safety rule under the CPSA, or to a similar rule, ban, standard or regulation under any other act enforced by the Commission, must be certified as complying with all applicable CPSC-enforced requirements. 15 U.S.C. 2063(a). Certification of children's products subject to a children's product safety rule must be based on testing conducted by a CPSC-accepted third party conformity assessment body. Id. 2063(a)(2). The Commission must publish an NOR for the accreditation of third party conformity assessment bodies to assess conformity with a children's product safety rule to which a children's product is subject. Id. 2063(a)(3). Thus, the proposed rule for 16 CFR part 1229, Safety Standard for Infant Bouncer Seats, if issued as a final rule, would be a children's product safety rule that requires the issuance of an NOR.

The Commission published a final rule, Requirements Pertaining to Third Party Conformity Assessment Bodies, 78 FR 15836 (March 12, 2013), codified at 16 CFR part 1112 (“part 1112”) and effective on June 10, 2013, which establishes requirements for accreditation of third party conformity assessment bodies to test for conformity with a children's product safety rule in accordance with section 14(a)(2) of the CPSA. Part 1112 also codifies all of the NORs issued previously by the Commission.

All new NORs for new children's product safety rules, such as the infant bouncer seat standard, require an amendment to part 1112. To meet the requirement that the Commission issue an NOR for the proposed bouncer seat standard, as part of this NPR, the Commission proposes to amend the existing rule that codifies the list of all NORs issued by the Commission to add bouncer seats to the list of children's product safety rules for which the CPSC has issued an NOR.

Test laboratories applying for acceptance as a CPSC-accepted third party conformity assessment body to test to the new standard for bouncer seats would be required to meet the third party conformity assessment body accreditation requirements in part 1112. When a laboratory meets the requirements as a CPSC-accepted third party conformity assessment body, the laboratory can apply to the CPSC to have 16 CFR part 1229, Safety Standard for Infant Bouncer Seats, included in the laboratory's scope of accreditation of CPSC safety rules listed for the laboratory on the CPSC Web site at: www.cpsc.gov/labsearch.

IX. Incorporation by Reference

Section 1229.2(a) of the proposed rule would incorporate by reference ASTM F2167-15. The Office of the Federal Register (“OFR”) has regulations concerning incorporation by reference. 1 CFR part 51. The regulations require that, for a proposed rule, agencies discuss in the preamble of the NPR ways that the materials the agency proposes to incorporate by reference are reasonably available to interested persons or how the agency worked to make the materials reasonably available. In addition, the preamble of the proposed rule must summarize the material. 1 CFR 51.5(a).

In accordance with the OFR's requirements, section V.B. of this preamble summarizes the provisions of ASTM F2167-15 that the Commission proposes to incorporate by reference. ASTM F2167-15 is copyrighted. By permission of ASTM, the standard can be viewed as a read-only document during the comment period on this NPR, at: http://www.astm.org/cpsc.htm. Interested persons may also purchase a copy of ASTM F2167-15 from ASTM International, 100 Bar Harbor Drive, P.O. Box 0700, West Conshohocken, PA 19428; http://www.astm.org/cpsc.htm. One may also inspect a copy at CPSC's Office of the Secretary, U.S. Consumer Product Safety Commission, Room 820, 4330 East West Highway, Bethesda, MD 20814, telephone 301-504-7923.Start Printed Page 63178

X. Effective Date

The Administrative Procedure Act (“APA”) generally requires that the effective date of a rule be at least 30 days after publication of the final rule. 5 U.S.C. 553(d). The Commission is proposing an effective date of 6 months after publication of the final rule in the Federal Register. Without evidence to the contrary, CPSC generally considers 6 months to be sufficient time for suppliers to come into compliance with a new standard, and a 6-month effective date is typical for other CPSIA section 104 rules. Six months is also the period that the Juvenile Products Manufacturers Association (“JPMA”) typically allows for products in the JPMA certification program to transition to a new standard once that standard is published. We also propose a 6-month effective date for the amendment to part 1112. We ask for comments on the proposed 6-month effective date.

XI. Regulatory Flexibility Act

A. Introduction

The Commission is issuing a proposed rule under the requirements of section 104 of the Consumer Product Safety Improvement Act (“CPSIA”) that would incorporate by reference the most recent ASTM standard for infant bouncer seats, ASTM F2167-15, with several modifications to the requirements for product warnings and instructional literature. In this section, we summarize staff's evaluation of the potential economic impact of the proposed rule on infant bouncer seats on small entities, including small businesses, as required by the Regulatory Flexibility Act (“RFA”). Section 603 of the RFA requires that agencies prepare an initial regulatory flexibility analysis (“IRFA”) and make it available to the public for comment when the general notice of proposed rulemaking (“NPR”) is published, unless the head of the agency certifies that the rule will not have a significant economic impact on a substantial number of small entities. The IRFA must describe the impact of the proposed rule on small entities and identify any alternatives that may reduce the impact. See Tab F, Staff NPR Briefing Package.

B. The Product

An infant bouncer seat is defined in ASTM F2167-15, Standard Consumer Safety Specification for Infant Bouncer Seats, as “a freestanding product intended to support an occupant in a reclined position to facilitate bouncing by the occupant, with the aid of a caregiver or by other means.” It is intended for “infants who have not developed the ability to sit up unassisted (approximately 0 to 6 months of age).” These products vary widely in price; they can be purchased for as little as $20, but can also easily cost more than $200.

C. The Market for Infant Bouncer Seats

Staff identified 22 firms (including large and small) supplying infant bouncer seats to the U.S. market, although there may be additional firms as well. These firms specialize primarily in the manufacture and/or distribution of children's products, including durable nursery products. The majority of the 22 known firms are domestic (including 8 manufacturers and 10 importers). The remaining four firms are foreign manufacturers.[10] Staff expects that the infant bouncer seats of 17 of these firms are already compliant with ASTM F2167 because the firms either: (1) Have their bouncers certified by the Juvenile Products Manufacturers Association (“JPMA”) (six firms); (2) claim compliance with the voluntary standard (ten firms); or (3) have been tested to the ASTM standard by CPSC staff (one firm).[11]

D. Reason for Agency Action and Legal Basis for the Proposed Rule

Section 104 of the CPSIA requires the CPSC to promulgate a mandatory standard for infant bouncer seats that is substantially the same as, or more stringent than, the voluntary standard if the Commission determines that a more stringent standard would further reduce the risk of injury associated with such products.

CPSC staff worked closely with ASTM to develop the revised requirements, test procedures, and warning labels that have been incorporated into ASTM F2167 since the rulemaking process started in January 2013 in an effort to reduce this risk. However, not all of staff's warning label recommendations were adopted into the most recent version of the voluntary standard, ASTM F2167-15. Therefore, the Commission proposes to incorporate by reference ASTM F2167-15, with the remaining modifications staff recommended to ASTM.

E. Requirements of the Proposed Rule

The Commission proposes adopting the voluntary ASTM standard for infant bouncer seats (ASTM F2167-15) with additional changes to the warning labels (in particular, the location of the fall hazard warning label) and a test to ensure the visibility of those labels on the product. A description of the current voluntary standard appears in section V of this preamble, and a description of the proposed modifications to the warning requirements appears in section VII of this preamble.

All firms would need to modify the text of their warnings for both the product and the instruction manual. The fall hazard warning would need to be re-located next to the child's head [12] and be visible when accessories are in use (such as a toy bar or an infant insert used for supporting a smaller child's upper body).

Staff discussed these changes with several ASTM members and supplier representatives. The possible economic impact of these changes on small business is discussed in Tab F of Staff's NPR Briefing Package and in section XI.G of this preamble.

F. Other Federal or State Rules

No federal rules duplicate, overlap, or conflict with the proposed rule.

G. Impact on Small Businesses

CPSC is aware of approximately 22 firms (large and small) currently marketing infant bouncer seats in the United States, 18 of which are domestic. Under U.S. Small Business Administration (“SBA”) guidelines, a manufacturer of infant bouncer seats is categorized as small if it has 500 or fewer employees, and importers and wholesalers are considered small if they have 100 or fewer employees. Our analysis is limited to domestic firms because SBA guidelines and definitions pertain to U.S.-based entities. Based on these guidelines, about 12 of the 22 firms are small—five domestic manufacturers and seven domestic importers. Additional unknown small domestic infant bouncer seats suppliers may be operating in the U.S. market.

1. Small Manufacturers

The economic impact of the proposed bouncer standard should be small for the five small domestic manufacturers, apart from third party testing costs. The Start Printed Page 63179bouncers of all of these firms already comply with the ASTM voluntary standard currently in effect for testing purposes (F2167-14). These firms are expected to remain compliant with the voluntary standard as it evolves, because they follow and, in at least three cases, actively participate in the standard development process. Therefore, compliance with the voluntary standard is part of an established business practice. ASTM F2167-15, the version the Commission proposes to incorporate, will be in effect by the time the mandatory standard becomes final and these firms are likely to be in compliance based on their history.

None of the small manufacturers typically includes more than four languages in their warnings (two firms use two languages; two firms use three languages; and one firm uses four languages). Based upon inspection of their products and the space available for the warnings, redesign should not be required for any of the bouncers supplied by the known small manufacturers. The firm using four languages might opt to redesign to give their product(s) a less cluttered appearance. However, discussions with a firm representative contacted by staff indicated that the firm was not concerned about the location of the warning labels.

Under section 14 of the CPSA, once the new infant bouncer seat requirements become effective, all manufacturers will be subject to the third party testing and certification requirements of the CPSA and the Commission's rule Testing and Labeling Pertaining to Product Certification at 16 CFR part 1107 (“the 1107 rule”). Third party testing will include any physical and mechanical test requirements specified in the final infant bouncer seats rule. Manufacturers and importers should already be conducting required lead testing for bouncers. Third party testing costs are in addition to the direct costs of meeting the infant bouncer seats standard.

All infant bouncer seats sold by U.S. manufacturers are currently tested to verify compliance with the ASTM standard, though not necessarily via third party. Thus, the impact to testing costs will be limited to the difference between the cost of third party tests and the cost of current testing regimes. As a frame of reference, suppliers have estimated that testing to the ASTM voluntary standard typically costs about $560-$800 per model sample. Based on an examination of firm revenues from recent Dun & Bradstreet or ReferenceUSAGov reports, the impact of third party testing to ASTM F2167-15 is unlikely to be economically significant for most small manufacturers (i.e., testing costs will be less than 1 percent of gross revenue). Although the Commission does not know how many samples will be needed to meet the “high degree of assurance” criterion required in the 1107 rule, over 24 units per model would be required to make testing costs to exceed one percent of gross revenue for the small manufacturer with the lowest gross revenue. One firm has a much larger number of infant bouncer models than the other small manufacturers, however, and its testing costs could exceed 1 percent of gross revenue if as few as seven units per model were required for testing. Note that this calculation assumes the rule would generate additional testing costs in the $560-$800 per model sample range. Given that all firms are conducting some testing already, this likely overestimates the impact of the rule with respect to testing costs. However, we do not know specifically how much the third party requirement adds to testing costs or precisely how many models are needed to meet the “high degree of assurance” criterion and cannot rule out a significant economic impact. We welcome comments regarding incremental costs due to third party testing (i.e., how much does moving from a voluntary to a mandatory third party testing regime add to testing costs, in total and on a per test basis). In addition, we seek comments regarding the accuracy of assuming that a “high degree of assurance” can be achieved with fewer than seven samples.

2. Small Importers

a. Small Importers With Compliant Infant Bouncer Seats

Five small importers of infant bouncer seats are currently in compliance with the voluntary standard and, based on prior compliance with the voluntary standard, would likely continue compliance as new versions of the voluntary standard are published. The bouncers supplied by these firms would, for the most part, only require modifications to meet the warning label changes.