|

Code of Federal Regulations (Last Updated: November 8, 2024) |

|

Title 10 - Energy |

|

Chapter II - Department of Energy |

|

SubChapter D - Energy Conservation |

|

Part 431 - Energy Efficiency Program for Certain Commercial and Industrial Equipment |

|

Subpart Y - Pumps |

Appendix C to Subpart Y of Part 431 - Uniform Test Method for the Measurement of Energy Efficiency of Dedicated-Purpose Pool Pumps

-

Appendix C to Subpart Y of Part 431 - Uniform Test Method for the Measurement of Energy Efficiency of Dedicated-Purpose Pool Pumps

Note:Any representations made on or after July 19, 2021, with respect to the energy use or efficiency of dedicated-purpose pool pumps subject to testing pursuant to 10 CFR 431.464(b) must be made in accordance with the results of testing pursuant to this appendix.

I. Test Procedure for Dedicated-Purpose Pool Pumps

A. General

A. 1 Test Method. To determine the weighted energy factor (WEF) for dedicated-purpose pool pumps, perform “wire-to-water” testing in accordance with HI 40.6-2014-B, except section 40.6.4.1, “Vertically suspended pumps”; section 40.6.4.2, “Submersible pumps”; section 40.6.5.3, “Test report”; section 40.6.5.5, “Test conditions”; section 40.6.5.5.2, “Speed of rotation during testing”; section 40.6.6.1, “Translation of test results to rated speed of rotation”; section 40.6.6.2, “Pump efficiency”; section 40.6.6.3, “Performance curve”; section A.7, “Testing at temperatures exceeding 30 °C (86 °F)”; and appendix B, “Reporting of test results”; (incorporated by reference, see § 431.463) with the modifications and additions as noted throughout the provisions below. Do not use the test points specified in section 40.6.5.5.1, “Test procedure” of HI 40.6-2014-B and instead use those test points specified in section D.3 of this appendix for the applicable dedicated-purpose pool pump variety and speed configuration. When determining overall efficiency, best efficiency point, or other applicable pump energy performance information, section 40.6.5.5.1, “Test procedure”; section 40.6.6.2, “Pump efficiency”; and section 40.6.6.3, “Performance curve” must be used, as applicable. For the purposes of applying this appendix, the term “volume per unit time,” as defined in section 40.6.2, “Terms and definitions,” of HI 40.6-2014-B shall be deemed to be synonymous with the term “flow rate” used throughout that standard and this appendix .

A. 2 Calculations and Rounding. All terms and quantities refer to values determined in accordance with the procedures set forth in this appendix for the rated pump. Perform all calculations using raw measured values without rounding. Round WEF, maximum head, vertical lift, and true priming time values to the tenths place (i.e., 0.1) and rated hydraulic horsepower to the thousandths place (i.e., 0.001). Round all other reported values to the hundredths place unless otherwise specified.

B. Measurement Equipment

B. 1 For the purposes of measuring flow rate, speed of rotation, temperature, and pump power output, the equipment specified in HI 40.6-2014-B Appendix C (incorporated by reference, see § 431.463) necessary to measure head, speed of rotation, flow rate, and temperature must be used and must comply with the stated accuracy requirements in HI 40.6-2014-B Table 40.6.3.2.3, except as specified in sections B.1.1 and B.1.2 of this appendix. When more than one instrument is used to measure a given parameter, the combined accuracy, calculated as the root sum of squares of individual instrument accuracies, must meet the specified accuracy requirements.

B. 1.1 Electrical measurement equipment for determining the driver power input to the motor or controls must be capable of measuring true root mean squared (RMS) current, true RMS voltage, and real power up to the 40th harmonic of fundamental supply source frequency, and have a combined accuracy of ±2.0 percent of the measured value at the fundamental supply source frequency.

B. 1.2 Instruments for measuring distance (e.g., height above the reference plane or water level) must be accurate to and have a resolution of at least ±0.1 inch.

B. 2 Calibration. Calibration requirements for instrumentation are specified in appendix D of HI 40.6-2014-B (incorporated by reference, see § 431.463). Historical calibration data may be used to justify time periods up to three times longer than those specified in table D.1 of HI 40.6-2014-B provided the supporting historical data shows maintenance of calibration of the given instrument up to the selected extended calibration interval on at least two unique occasions, based on the interval specified in HI 40.6-2014-B.

C. Test Conditions and Tolerances

C. 1 Pump Specifications. Conduct testing at full impeller diameter in accordance with the test conditions, stabilization requirements, and specifications of HI 40.6-2014-B section 40.6.3, “Pump efficiency testing”; section 40.6.4, “Considerations when determining the efficiency of a pump”; section 40.6.5.4 (including appendix A), “Test arrangements”; and section 40.6.5.5, “Test conditions” (incorporated by reference, see § 431.463).

C. 2 Power Supply Requirements. The following conditions also apply to the mains power supplied to the DPPP motor or controls, if any:

(1) Maintain the voltage within ±5 percent of the rated value of the motor,

(2) Maintain the frequency within ±1 percent of the rated value of the motor,

(3) Maintain the voltage unbalance of the power supply within ±3 percent of the value with which the motor was rated, and

(4) Maintain total harmonic distortion below 12 percent throughout the test.

C. 3 Test Conditions. Testing must be carried out with water that is between 50 and 107 °F with less than or equal to 15 nephelometric turbidity units (NTU).

C. 4 Tolerances. For waterfall pumps, multi-speed self-priming and non-self-priming pool filter pumps, and variable-speed self-priming and non-self-priming pool filter pumps all measured load points must be within ±2.5 percent of the specified head value and comply with any specified flow values or thresholds. For all other dedicated-purpose pool pumps, all measured load points must be within the greater of ±2.5 percent of the specified flow rate values or ±0.5 gpm and comply with any specified head values or thresholds.

D. Data Collection and Stabilization

D. 1 Damping Devices. Use of damping devices, as described in section 40.6.3.2.2 of HI 40.6-2014-B (incorporated by reference, see § 431.463), are only permitted to integrate up to the data collection interval used during testing.

D. 2 Stabilization. Record data at any tested load point only under stabilized conditions, as defined in HI 40.6-2014-B section 40.6.5.5.1 (incorporated by reference, see § 431.463), where a minimum of two measurements are used to determine stabilization.

D. 3 Test Points. Measure the flow rate in gpm, pump total head in ft, the driver power input in W, and the speed of rotation in rpm at each load point specified in Table 1 of this appendix for each DPPP variety and speed configuration:

Table 1 - Load Points (i) and Weights (wi) for Each DPPP Variety and Speed Configuration

DPPP varieties Speed configuration(s) Number of load points

(n)Load point

(i)Test points Flow rate

(Q) (GPM)Head

(H) (ft)Speed

(rpm)Self-Priming Pool Filter Pumps And Non-Self-Priming Pool Filter Pumps Single-speed dedicated-purpose pool pumps and all self-priming and non-self-priming pool filter pumps not meeting the definition of two-*, multi-, or variable-speed dedicated-purpose pool pump 1 High Qhigh (gpm) = Qmax__speed@C ** H = 0.0082 × Qhigh2 Maximum speed. Two-speed dedicated-purpose pool pumps * 2 Low Qlow (gpm) = Flow rate associated with specified head and speed that is not below:

• 31.1 gpm if rated hydraulic horsepower is >0.75 or

• 24.7 gpm if rated hydraulic horsepower is ≤0.75H = 0.0082 × Qlow2 Lowest speed capable of meeting the specified flow and head values, if any. *** High Qhigh (gpm) = Qmax__speed@C ** H = 0.0082 × Qlow2 Maximum speed. Multi-speed and variable-speed dedicated-purpose pool pumps 2 Low Qlow (gpm) =

• If rated hydraulic horsepower is >0.75, then Qlow ≥31.1 gpm

• If rated hydraulic horsepower is ≤0.75, then Qlow ≥24.7 gpmH = 0.0082 × Qlow2 Lowest speed capable of meeting the specified flow and head values. High Qhigh (gpm) ≥0.8 × Qmax__speed@C ** H = 0.0082 × Qhigh2 Lowest speed capable of meeting the specified flow and head values. Waterfall Pumps Single-speed dedicated-purpose pool pumps 1 High Qlow (gpm) = Flow corresponding to specified head 17.0 ft Maximum speed. Pressure Cleaner Booster Pumps Any 1 High 10.0 gpm ≥60.0 ft Lowest speed capable of meeting the specified flow and head values. E. Calculations

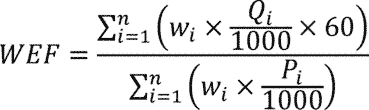

E. 1 Determination of Weighted Energy Factor. Determine the WEF as a ratio of the measured flow and driver power input to the dedicated-purpose pool pump in accordance with the following equation:

Where:

WEF = Weighted Energy Factor in kgal/kWh;

Wi = weighting factor at each load point i, as specified in section E.2 of this appendix;

Qi = flow at each load point i, in gpm;

Pi = driver power input to the motor (or controls, if present) at each load point i, in watts;

i = load point(s), defined uniquely for each DPPP variety and speed configuration as specified in section D.3 of this appendix; and

n = number of load point(s), defined uniquely for each DPPP variety and speed configuration as specified in section D.3 of this appendix.

E. 2 Weights. When determining WEF, apply the weights specified in Table 2 of this appendix for the applicable load points, DPPP varieties, and speed configurations:

Table 2 - Load Point Weights (wi)

DPPP varieties Speed configuration(s) Load point(s)

iLow flow High flow Self-Priming Pool Filter Pumps and Non-Self-Priming Pool Filter Pumps Single-speed dedicated-purpose pool pumps and all self-priming and non-self-priming pool filter pumps not meeting the definition of two-*, multi-, or variable-speed dedicated-purpose pool pump 1.0 Two-speed dedicated-purpose pool pumps * 0.80 0.20 Multi-speed and variable-speed dedicated-purpose pool pumps 0.80 0.20 Waterfall Pumps Single-speed dedicated-purpose pool pumps 1.0 Pressure Cleaner Booster Pump Any 1.0 E. 3 Determination of Horsepower and True Power Factor Metrics

E. 3.1 Determine the pump power output at any load point i using the following equation:

Where:

Pu,i = the measured pump power output at load point i of the tested pump, in hp;

Qi = the measured flow rate at load point i of the tested pump, in gpm;

Hi = pump total head at load point i of the tested pump, in ft; and

SG = the specific gravity of water at specified test conditions, which is equivalent to 1.00.

E. 3.1.1 Determine the rated hydraulic horsepower as the pump power output measured on the reference curve at maximum rotating speed and full impeller diameter for the rated pump.

E. 3.2 For dedicated-purpose pool pumps with single-phase AC motors or DC motors, determine the dedicated-purpose pool pump nominal motor horsepower as the product of the measured full load speed and torque, adjusted to the appropriate units, as shown in the following equation:

Where:

Pnm = the dedicated-purpose pool pump nominal total horsepower at full load, in hp;

T = output torque at full load, in lb-ft; and

n = the motor speed at full load, in rpm.

Full-load speed and torque shall be determined based on the maximum continuous duty motor power output rating allowable for the motor's nameplate ambient rating and insulation class.

E. 3.2.1 For single-phase AC motors, determine the measured speed and torque at full load according to either section E.3.2.1.1 or E.3.2.1.2 of this appendix.

E. 3.2.1.1 Use the procedures in section 3.2, “Tests with load”; section 4 “Testing facilities”; section 5.2 “Mechanical measurements”; section 5.3 “Temperature measurements”; and section 6 “Tests” of IEEE 114-2010 (incorporated by reference, see § 431.463), or

E. 3.2.1.2 Use the applicable procedures in section 5, “General test requirements” and section 6, “Tests” of CSA C747-2009 (RA 2014); except in section 6.4(b) the conversion factor shall be 5252, only measurements at full load are required in section 6.5, and section 6.6 shall be disregarded (incorporated by reference, see § 431.463).

E. 3.2.2 For DC motors, determine the measured speed and torque at full load according to either section E.3.2.2.1 or E.3.2.2.2 of this appendix.

E. 3.2.2.1 Use the procedures in section 3.1, “Instrument Selection Factors”; section 3.4 “Power Measurement”: Section 3.5 “Power Sources”; section 4.1.2 “Ambient Air”; section 4.1.4 “Direction of Rotation”; section 5.4.1 “Reference Conditions”; and section 5.4.3.2 “Dynomometer or Torquemeter Method” of IEEE 113-1985 (incorporated by reference, see § 431.463), or

E. 3.2.2.2 Use the applicable procedures in section 5, “General test requirements” and section 6, “Tests” of CSA C747-2009 (RA 2014); except in section 6.4(b) the conversion factor shall be 5252, only measurements at full load are required in section 6.5, and section 6.6 shall be disregarded (incorporated by reference, see § 431.463).

E. 3.3 For dedicated-purpose pool pumps with single-phase AC motors or DC motors, the dedicated-purpose pool pump service factor is equal to 1.0.

E. 3.4 Determine the dedicated-purpose pool pump motor total horsepower according to section E.3.4.1 of this appendix for dedicated-purpose pool pumps with single-phase AC motors or DC motors and section E.3.4.2 of this appendix for dedicated-purpose pool pumps with polyphase AC motors.

E. 3.4.1 For dedicated-purpose pool pumps with single-phase AC motors or DC motors, determine the dedicated-purpose pool pump motor total horsepower as the product of the dedicated-purpose pool pump nominal motor horsepower, determined in accordance with section E.3.2 of this appendix, and the dedicated-purpose pool pump service factor, determined in accordance with section E.3.3 of this appendix.

E. 3.4.2 For dedicated-purpose pool pumps with polyphase AC induction motors, determine the dedicated-purpose pool pump motor total horsepower as the product of the rated nominal motor horsepower and the rated service factor of the motor.

E. 3.5 Determine the true power factor at each applicable load point specified in Table 1 of this appendix for each DPPP variety and speed configuration as a ratio of driver power input to the motor (or controls, if present) (Pi), in watts, divided by the product of the voltage in volts and the current in amps at each load point i, as shown in the following equation:

Where:

PFi = true power factor at each load point i, dimensionless;

Pi = driver power input to the motor (or controls, if present) at each load point i, in watts;

Vi = voltage at each load point i, in volts;

Ii = current at each load point i, in amps; and

i = load point(s), defined uniquely for each DPPP variety and speed configuration as specified in section D.3 of this appendix.

E. 4 Determination of Maximum Head. Determine the maximum head for self-priming pool filter pumps, non-self-priming pool filter pumps, and waterfall pumps by measuring the head at maximum speed and the minimum flow rate at which the pump is designed to operate continuously or safely, where the minimum flow rate is assumed to be zero unless stated otherwise in the manufacturer literature.

F. Determination of Self-Priming Capability

F. 1 Test Method. Determine the vertical lift and true priming time of non-self-priming pool filter pumps and self-priming pool filter pumps that are not already certified as self-priming under NSF/ANSI 50-2015 (incorporated by reference, see § 431.463) by testing such pumps pursuant to section C.3 of appendix C of NSF/ANSI 50-2015, except for the modifications and exceptions listed in the following sections F.1.1 through F.1.5 of this appendix:

F. 1.1 Where section C.3.2, “Apparatus,” and section C.3.4, “Self-priming capability test method,” of NSF/ANSI 50-2015 (incorporated by reference, see § 431.463) state that the “suction line must be essentially as shown in annex C, figure C.1;” the phrase “essentially as shown in Annex C, figure C.1” means:

(1) The centerline of the pump impeller shaft is situated a vertical distance equivalent to the specified vertical lift (VL), calculated in accordance with section F.1.1.1. of this appendix, above the water level of a water tank of sufficient volume as to maintain a constant water surface level for the duration of the test;

(2) The pump draws water from the water tank with a riser pipe that extends below the water level a distance of at least 3 times the riser pipe diameter (i.e., 3 pipe diameters);

(3) The suction inlet of the pump is at least 5 pipe diameters from any obstructions, 90° bends, valves, or fittings; and

(4) The riser pipe is of the same pipe diameter as the pump suction inlet.

F. 1.1.1 The vertical lift (VL) must be normalized to 5.0 feet at an atmospheric pressure of 14.7 psia and a water density of 62.4 lb/ft3 in accordance with the following equation:

Where:

VL = vertical lift of the test apparatus from the waterline to the centerline of the pump impeller shaft, in ft;

ρtest = density of test fluid, in lb/ft3; and

Pabs,test = absolute barometric pressure of test apparatus location at centerline of pump impeller shaft, in psia.

F. 1.2 The equipment accuracy requirements specified in section B, “Measurement Equipment,” of this appendix also apply to this section F, as applicable.

F. 1.2.1 All measurements of head (gauge pressure), flow, and water temperature must be taken at the pump suction inlet and all head measurements must be normalized back to the centerline of the pump impeller shaft in accordance with section A.3.1.3.1 of HI 40.6-2014-B (incorporated by reference, see § 431.463).

F. 1.3 All tests must be conducted with clear water that meets the requirements adopted in section C.3 of this appendix.

F. 1.4 In section C.3.4, “Self-priming capability test method,” of NSF/ANSI 50-2015 (incorporated by reference, see § 431.463), “the elapsed time to steady discharge gauge reading or full discharge flow” is determined when the changes in head and flow, respectively, are within the tolerance values specified in table 40.6.3.2.2, “Permissible amplitude of fluctuation as a percentage of mean value of quantity being measured at any test point,” of HI 40.6-2014-B (incorporated by reference, see § 431.463). The measured priming time (MPT) is determined as the point in time when the stabilized load point is first achieved, not when stabilization is determined. In addition, the true priming time (TPT) is equivalent to the MPT.

F. 1.5 The maximum true priming time for each test run must not exceed 10.0 minutes. Disregard section C.3.5 of NSF/ANSI 50-2015 (incorporated by reference, see § 431.463).

G. Optional Testing and Calculations

G. 1 Replacement Dedicated-Purpose Pool Pump Motors. To determine the WEF for replacement DPPP motors, test each replacement DPPP motor paired with each dedicated-purpose pool pump bare pump for which the replacement DPPP motor is advertised to be paired, as stated in the manufacturer's literature for that replacement DPPP motor model, according to the testing and calculations described in sections A, B, C, D, and E of this appendix. Alternatively, each replacement DPPP motor may be tested with the most consumptive dedicated-purpose pool pump bare pump for which it is advertised to be paired, as stated in the manufacturer's literature for that replacement DPPP motor model. If a replacement DPPP motor is not advertised to be paired with any specific dedicated-purpose pool pump bare pumps, test with the most consumptive dedicated-purpose pool pump bare pump available.

[82 FR 36924, Aug. 7, 2017]